Intro

Streamline vehicle checks with 5 Dot Inspection Forms, utilizing digital inspection tools and mobile apps for efficient vehicle assessments, improving safety and compliance with regulatory standards.

The importance of regular inspections cannot be overstated, especially in industries where safety and compliance are paramount. One tool that has gained popularity in recent years is the 5-dot inspection form. This simple yet effective method allows inspectors to quickly and easily assess the condition of equipment, vehicles, or facilities, and identify potential issues before they become major problems. In this article, we will delve into the world of 5-dot inspection forms, exploring their benefits, working mechanisms, and steps for implementation.

The use of 5-dot inspection forms has become increasingly widespread, and for good reason. By providing a standardized and systematic approach to inspections, these forms help to ensure that nothing is overlooked, and that all necessary checks are performed. This, in turn, can help to prevent accidents, reduce downtime, and improve overall efficiency. Whether you are a seasoned inspector or just starting out, understanding the ins and outs of 5-dot inspection forms is essential for success.

In today's fast-paced and highly regulated environment, the need for effective inspection tools has never been greater. With the rise of new technologies and increasingly complex systems, the potential for errors and oversights has increased exponentially. This is where 5-dot inspection forms come in – providing a simple, yet powerful solution for inspectors and organizations alike. By leveraging the benefits of these forms, businesses can improve safety, reduce costs, and enhance overall performance.

Introduction to 5-Dot Inspection Forms

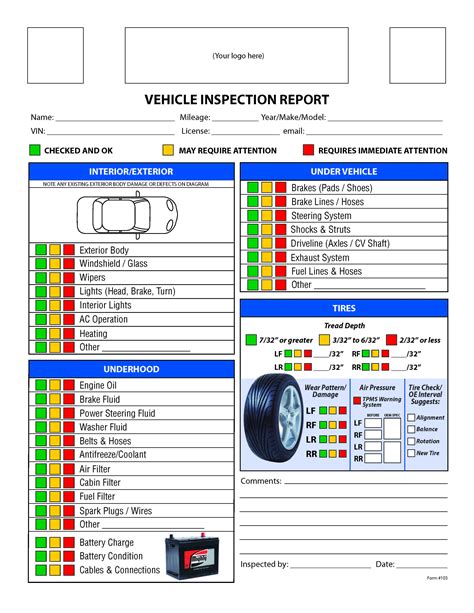

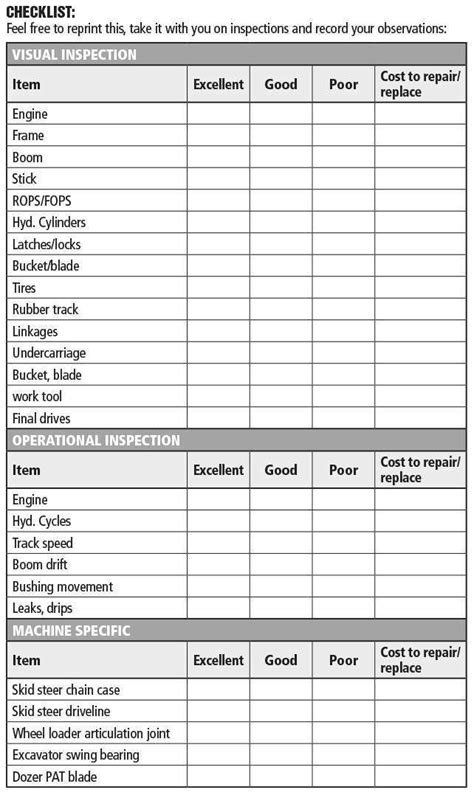

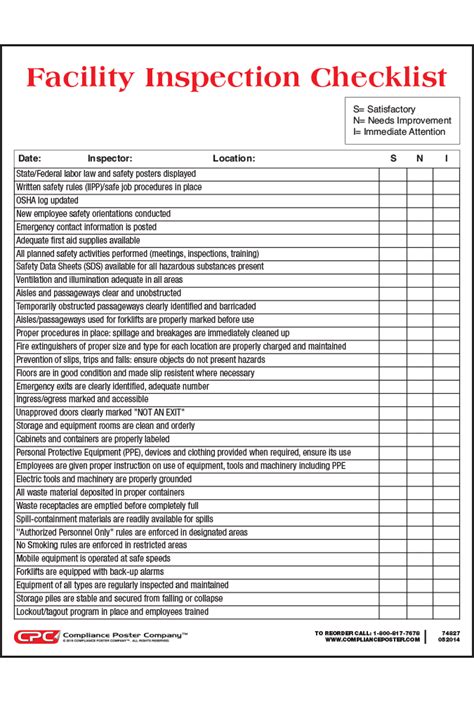

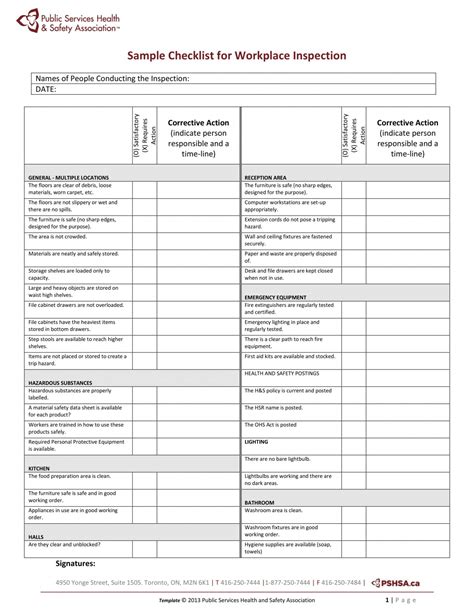

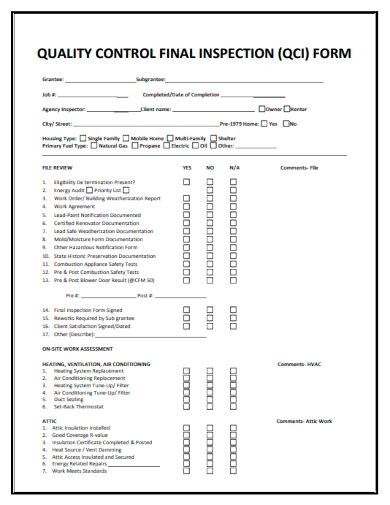

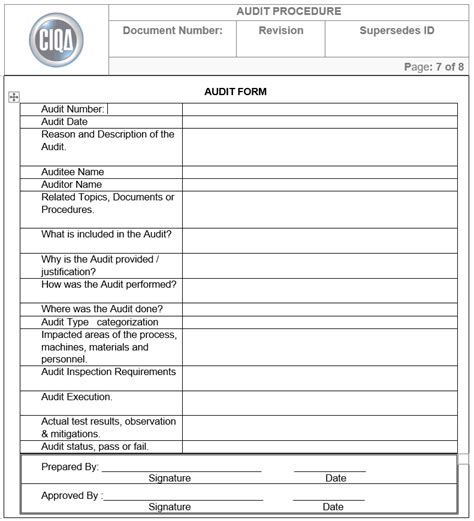

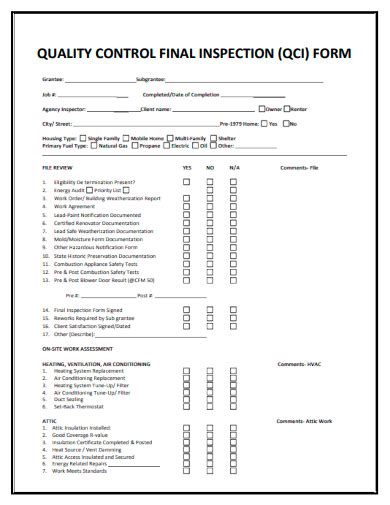

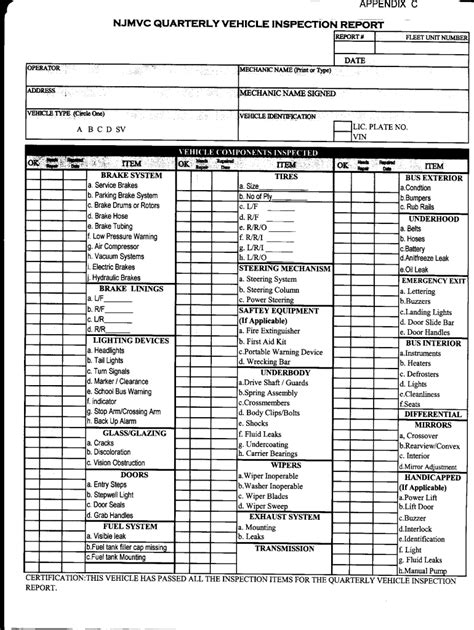

A 5-dot inspection form is a type of checklist used to evaluate the condition of equipment, vehicles, or facilities. The form typically consists of a series of questions or statements, each with a corresponding set of dots (usually five) that indicate the level of compliance or condition. Inspectors can then use these forms to quickly and easily assess the status of the item being inspected, and identify any potential issues or areas for improvement.

Benefits of 5-Dot Inspection Forms

The benefits of using 5-dot inspection forms are numerous. Some of the most significant advantages include:

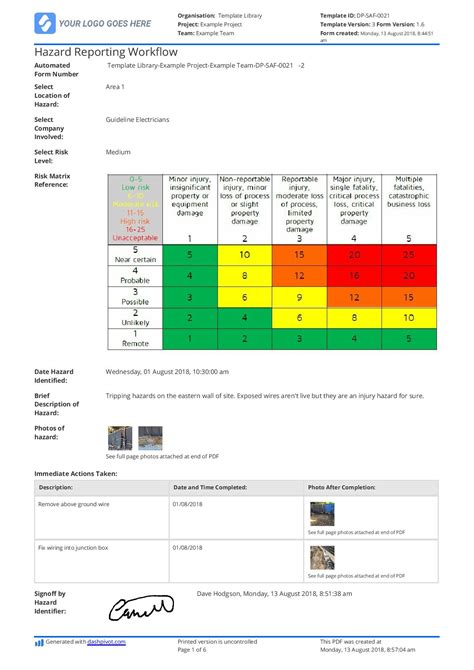

- Improved safety: By identifying potential hazards and issues before they become major problems, 5-dot inspection forms can help to prevent accidents and reduce the risk of injury or damage.

- Increased efficiency: These forms provide a standardized and systematic approach to inspections, helping to ensure that all necessary checks are performed quickly and easily.

- Enhanced compliance: 5-dot inspection forms can help organizations to demonstrate compliance with regulatory requirements and industry standards.

- Reduced costs: By identifying and addressing potential issues early on, businesses can avoid costly repairs and downtime.

Working Mechanisms of 5-Dot Inspection Forms

So, how do 5-dot inspection forms work? The process is relatively straightforward. Inspectors begin by reviewing the form and assessing the condition of the item being inspected. They then use the dots to indicate the level of compliance or condition, with each dot corresponding to a specific rating or score. The ratings can be customized to suit the specific needs of the organization, but common examples include:

- 5 dots: Excellent condition, no issues or defects.

- 4 dots: Good condition, minor issues or defects.

- 3 dots: Fair condition, noticeable issues or defects.

- 2 dots: Poor condition, significant issues or defects.

- 1 dot: Critical condition, major issues or defects that require immediate attention.

Steps for Implementing 5-Dot Inspection Forms

Implementing 5-dot inspection forms is a relatively simple process. Here are the steps to follow:

- Identify the items to be inspected: Determine which equipment, vehicles, or facilities will be subject to the 5-dot inspection process.

- Develop the inspection form: Create a customized 5-dot inspection form that meets the specific needs of your organization.

- Train inspectors: Ensure that all inspectors understand the 5-dot inspection process and how to use the forms effectively.

- Conduct inspections: Begin conducting regular inspections using the 5-dot forms, and review the results to identify areas for improvement.

- Review and revise: Continuously review and revise the 5-dot inspection process to ensure that it remains effective and efficient.

Best Practices for Using 5-Dot Inspection Forms

To get the most out of 5-dot inspection forms, it's essential to follow best practices. Here are some tips to keep in mind:

- Use a standardized format: Ensure that all 5-dot inspection forms follow a consistent format, making it easier to compare results and track progress.

- Provide clear instructions: Make sure that inspectors understand how to use the forms and what each dot rating means.

- Conduct regular inspections: Regular inspections help to identify potential issues before they become major problems.

- Review and act on results: Take action on the results of the inspections, addressing any issues or defects that are identified.

Common Applications of 5-Dot Inspection Forms

5-dot inspection forms have a wide range of applications, including:

- Vehicle inspections: 5-dot forms can be used to inspect vehicles, identifying any issues or defects that need to be addressed.

- Equipment inspections: These forms can be used to inspect equipment, such as machinery or tools, to ensure that it is in good working condition.

- Facility inspections: 5-dot forms can be used to inspect facilities, such as buildings or warehouses, to identify any safety hazards or areas for improvement.

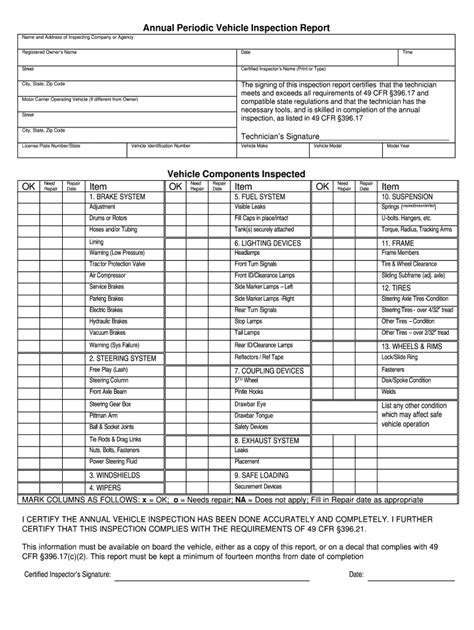

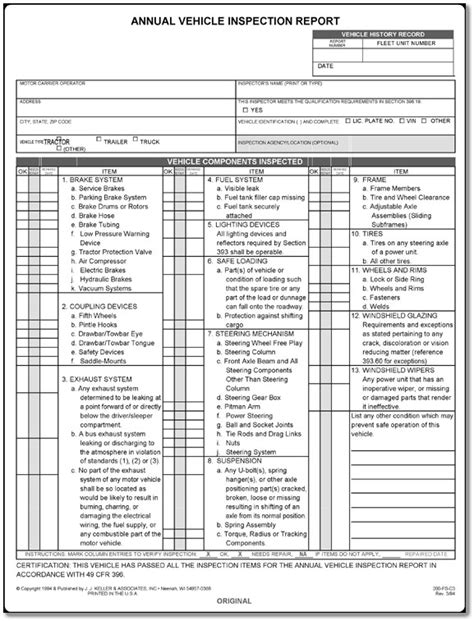

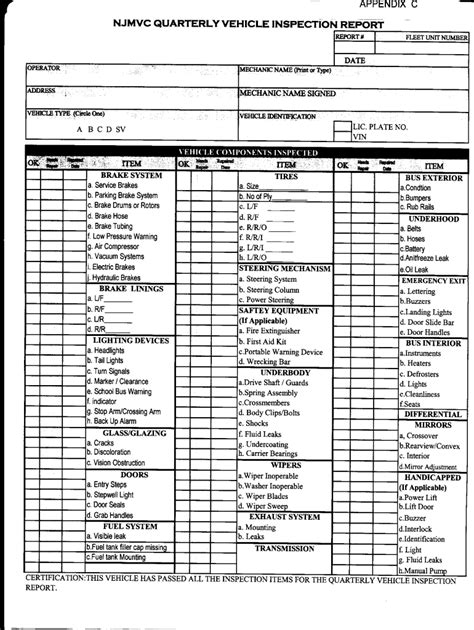

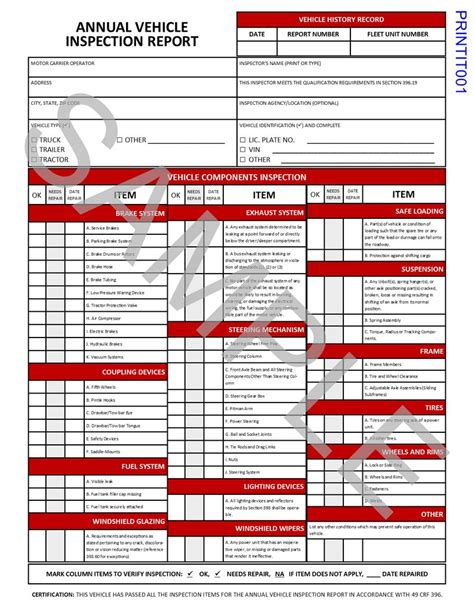

Gallery of 5-Dot Inspection Forms

5-Dot Inspection Forms Image Gallery

What is a 5-dot inspection form?

+A 5-dot inspection form is a type of checklist used to evaluate the condition of equipment, vehicles, or facilities. The form typically consists of a series of questions or statements, each with a corresponding set of dots (usually five) that indicate the level of compliance or condition.

How do I implement 5-dot inspection forms in my organization?

+To implement 5-dot inspection forms, identify the items to be inspected, develop a customized form, train inspectors, conduct regular inspections, and review and revise the process as needed.

What are the benefits of using 5-dot inspection forms?

+The benefits of using 5-dot inspection forms include improved safety, increased efficiency, enhanced compliance, and reduced costs. These forms help to identify potential issues before they become major problems, reducing the risk of accidents and downtime.

Can 5-dot inspection forms be customized to meet the specific needs of my organization?

+Yes, 5-dot inspection forms can be customized to meet the specific needs of your organization. The form can be tailored to include the specific items, questions, and ratings that are relevant to your business.

How often should I conduct 5-dot inspections?

+The frequency of 5-dot inspections will depend on the specific needs of your organization and the items being inspected. Regular inspections should be conducted to ensure that potential issues are identified and addressed in a timely manner.

In

Final Thoughts

we hope that this article has provided you with a comprehensive understanding of 5-dot inspection forms and their applications. By leveraging the benefits of these forms, businesses can improve safety, reduce costs, and enhance overall performance. Whether you are a seasoned inspector or just starting out, we encourage you to explore the world of 5-dot inspection forms and discover the difference they can make in your organization. If you have any questions or comments, please don't hesitate to reach out. Share this article with your colleagues and friends, and let's work together to create a safer and more efficient work environment.