Intro

Streamline crane maintenance with a comprehensive Crane Inspection Printable Checklist, covering safety protocols, wire rope inspection, and equipment verification to ensure operational efficiency and compliance.

The importance of regular crane inspections cannot be overstated. Cranes are complex machines that play a critical role in various industries, including construction, manufacturing, and shipping. However, they can also pose significant risks to workers and the general public if not properly maintained. A crane inspection printable checklist is an essential tool for ensuring that cranes are in good working condition and compliant with relevant safety standards. In this article, we will discuss the benefits of using a crane inspection printable checklist, its components, and how it can be used to improve crane safety.

Regular crane inspections are crucial for identifying potential hazards and preventing accidents. A crane inspection printable checklist provides a systematic approach to inspecting cranes, ensuring that all critical components are examined and evaluated. This checklist can be used by crane operators, maintenance personnel, and safety inspectors to verify that cranes are in compliance with industry standards and regulations. By using a crane inspection printable checklist, individuals can ensure that cranes are safe to operate, reducing the risk of accidents and injuries.

The use of a crane inspection printable checklist also promotes consistency and accuracy in the inspection process. It helps to ensure that all necessary checks are performed, and that nothing is overlooked. This is particularly important in industries where cranes are used extensively, such as construction and manufacturing. By using a standardized checklist, individuals can ensure that cranes are inspected thoroughly, reducing the risk of human error and improving overall safety.

Benefits of a Crane Inspection Printable Checklist

A crane inspection printable checklist offers numerous benefits, including improved safety, increased efficiency, and reduced costs. By using a checklist, individuals can ensure that cranes are inspected regularly, reducing the risk of accidents and injuries. This, in turn, can lead to cost savings, as the cost of repairing or replacing damaged equipment can be substantial. Additionally, a crane inspection printable checklist can help to improve productivity, as cranes that are in good working condition can operate more efficiently.

Some of the key benefits of a crane inspection printable checklist include:

- Improved safety: A crane inspection printable checklist helps to identify potential hazards and prevent accidents.

- Increased efficiency: By using a checklist, individuals can ensure that cranes are inspected regularly, reducing downtime and improving productivity.

- Reduced costs: A crane inspection printable checklist can help to reduce costs associated with repairing or replacing damaged equipment.

- Enhanced compliance: A checklist can help to ensure that cranes are in compliance with industry standards and regulations.

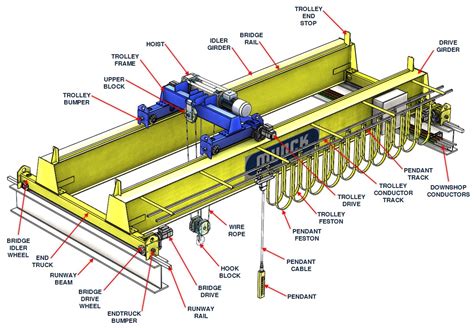

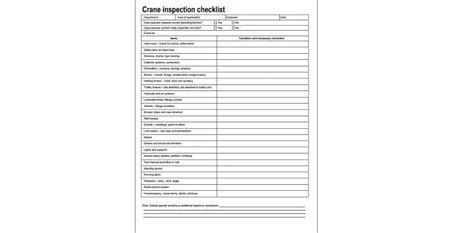

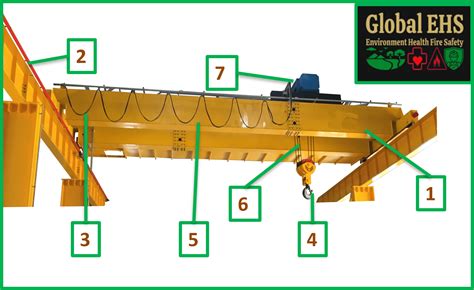

Components of a Crane Inspection Printable Checklist

A crane inspection printable checklist typically includes a range of components, such as:

- Pre-operational checks: These checks are performed before the crane is used, to ensure that it is in good working condition.

- Operational checks: These checks are performed during operation, to ensure that the crane is functioning properly.

- Post-operational checks: These checks are performed after the crane is used, to ensure that it is properly shut down and secured.

- Weekly and monthly checks: These checks are performed on a regular basis, to ensure that the crane is properly maintained.

Some of the key components of a crane inspection printable checklist include:

- Wire rope inspection: This involves inspecting the wire rope for signs of wear or damage.

- Sheave and drum inspection: This involves inspecting the sheaves and drums for signs of wear or damage.

- Brake inspection: This involves inspecting the brakes to ensure that they are functioning properly.

- Hydraulic system inspection: This involves inspecting the hydraulic system to ensure that it is functioning properly.

How to Use a Crane Inspection Printable Checklist

Using a crane inspection printable checklist is relatively straightforward. The following steps can be followed:

- Obtain a copy of the checklist: This can be downloaded from the internet or obtained from a reputable supplier.

- Review the checklist: Before using the checklist, review it to ensure that it is comprehensive and covers all necessary components.

- Perform the inspection: Use the checklist to perform the inspection, ensuring that all necessary checks are performed.

- Record the results: Record the results of the inspection, including any defects or issues that are identified.

- Take corrective action: Take corrective action to address any defects or issues that are identified during the inspection.

Some tips for using a crane inspection printable checklist include:

- Ensure that the checklist is comprehensive and covers all necessary components.

- Use the checklist regularly, to ensure that the crane is properly maintained.

- Record the results of the inspection, including any defects or issues that are identified.

- Take corrective action to address any defects or issues that are identified during the inspection.

Best Practices for Crane Inspection

There are several best practices that can be followed to ensure that crane inspections are performed effectively. These include:

- Ensuring that the inspection is performed by a qualified individual.

- Using a comprehensive checklist to ensure that all necessary components are inspected.

- Recording the results of the inspection, including any defects or issues that are identified.

- Taking corrective action to address any defects or issues that are identified during the inspection.

Some additional best practices for crane inspection include:

- Ensuring that the crane is properly maintained, to prevent defects and issues from arising.

- Using proper lockout/tagout procedures, to ensure that the crane is properly shut down and secured during maintenance.

- Ensuring that all personnel are properly trained, to ensure that they are aware of the risks associated with crane operation and maintenance.

Common Crane Inspection Mistakes

There are several common mistakes that can be made during crane inspections. These include:

- Failing to use a comprehensive checklist, to ensure that all necessary components are inspected.

- Failing to record the results of the inspection, including any defects or issues that are identified.

- Failing to take corrective action to address any defects or issues that are identified during the inspection.

Some additional common crane inspection mistakes include:

- Failing to ensure that the inspection is performed by a qualified individual.

- Failing to use proper lockout/tagout procedures, to ensure that the crane is properly shut down and secured during maintenance.

- Failing to ensure that all personnel are properly trained, to ensure that they are aware of the risks associated with crane operation and maintenance.

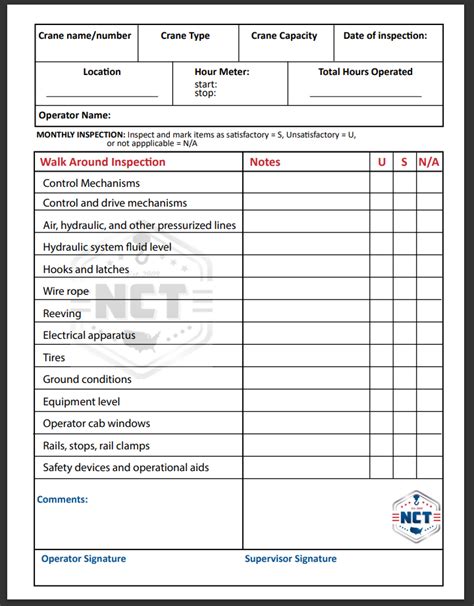

Crane Inspection Frequency

The frequency of crane inspections depends on several factors, including the type of crane, its usage, and the industry in which it is used. In general, cranes should be inspected regularly, to ensure that they are properly maintained and safe to operate.

Some common crane inspection frequencies include:

- Daily inspections: These are performed before the crane is used, to ensure that it is in good working condition.

- Weekly inspections: These are performed on a weekly basis, to ensure that the crane is properly maintained.

- Monthly inspections: These are performed on a monthly basis, to ensure that the crane is properly maintained.

- Annual inspections: These are performed on an annual basis, to ensure that the crane is properly maintained and compliant with industry standards and regulations.

Crane Inspection Tools and Equipment

There are several tools and equipment that can be used to perform crane inspections. These include:

- Visual inspection equipment, such as binoculars and cameras.

- Measuring equipment, such as tape measures and calipers.

- Testing equipment, such as load testing devices.

- Safety equipment, such as hard hats and safety glasses.

Some additional crane inspection tools and equipment include:

- Wire rope inspection equipment, such as wire rope lubricators and cleaners.

- Sheave and drum inspection equipment, such as sheave and drum gauges.

- Brake inspection equipment, such as brake test devices.

- Hydraulic system inspection equipment, such as hydraulic pressure test devices.

Gallery of Crane Inspection

Crane Inspection Image Gallery

What is a crane inspection printable checklist?

+A crane inspection printable checklist is a document that outlines the necessary steps to inspect a crane, ensuring that it is in good working condition and compliant with industry standards and regulations.

Why is it important to use a crane inspection printable checklist?

+Using a crane inspection printable checklist is important because it helps to ensure that cranes are properly maintained, reducing the risk of accidents and injuries. It also helps to ensure that cranes are compliant with industry standards and regulations, reducing the risk of fines and penalties.

How often should a crane be inspected?

+The frequency of crane inspections depends on several factors, including the type of crane, its usage, and the industry in which it is used. In general, cranes should be inspected regularly, to ensure that they are properly maintained and safe to operate.

In summary, a crane inspection printable checklist is a valuable tool for ensuring that cranes are properly maintained and safe to operate. By using a comprehensive checklist, individuals can ensure that all necessary components are inspected, reducing the risk of accidents and injuries. We encourage readers to share their experiences with crane inspections and to ask any questions they may have about the topic. Additionally, we invite readers to explore our other articles on crane safety and maintenance, to learn more about how to keep cranes in good working condition.