Intro

Discover expert 3D printable BJD tips for doll-making, including resin printing, ball-joint assembly, and customization techniques for unique ball-jointed dolls.

The world of 3D printing has opened up new possibilities for hobbyists and collectors of Ball-Jointed Dolls (BJDs). With the ability to create customized and intricate designs, 3D printing has become an exciting medium for BJD enthusiasts. However, working with 3D printed BJDs can be challenging, especially for those new to the hobby. In this article, we will delve into the world of 3D printable BJDs, exploring the benefits, challenges, and tips for working with these unique dolls.

The rise of 3D printing has democratized the creation of BJDs, allowing artists and hobbyists to design and print their own dolls. This has led to a proliferation of unique and customized BJDs, each with its own distinct character and style. For collectors, 3D printed BJDs offer a new level of exclusivity and rarity, as each doll can be tailored to individual tastes and preferences. Whether you're a seasoned collector or just starting out, 3D printed BJDs are an exciting development in the world of doll collecting.

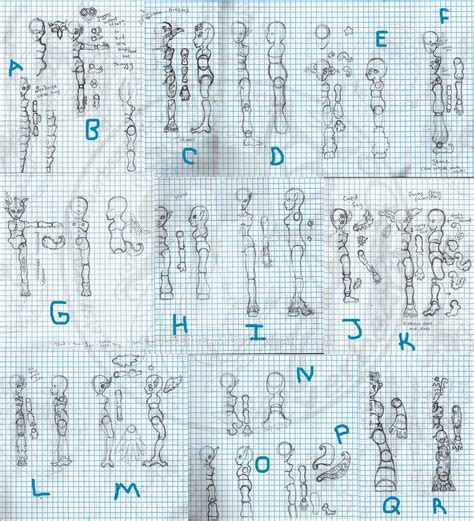

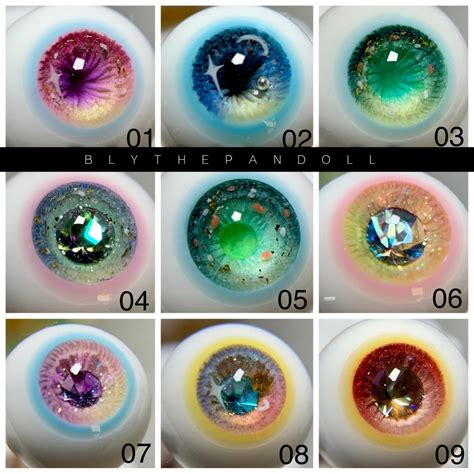

One of the primary advantages of 3D printed BJDs is the level of customization they offer. With traditional BJDs, collectors are limited to the designs and styles created by manufacturers. In contrast, 3D printed BJDs can be designed and printed to meet individual specifications, allowing collectors to create truly one-of-a-kind dolls. This level of customization has led to a thriving community of BJD enthusiasts, who share and collaborate on designs, tips, and techniques for working with 3D printed dolls.

Introduction to 3D Printable BJDs

Benefits of 3D Printed BJDs

The benefits of 3D printed BJDs are numerous, ranging from customization options to cost-effectiveness. Some of the key advantages include: * Customization: 3D printed BJDs can be designed and printed to meet individual specifications, allowing for a level of exclusivity and rarity. * Cost-effectiveness: 3D printing can be more cost-effective than traditional manufacturing methods, making it possible to create high-quality BJDs at a lower cost. * Community involvement: The 3D printed BJD community is active and collaborative, with many enthusiasts sharing designs, tips, and techniques online.Designing 3D Printable BJDs

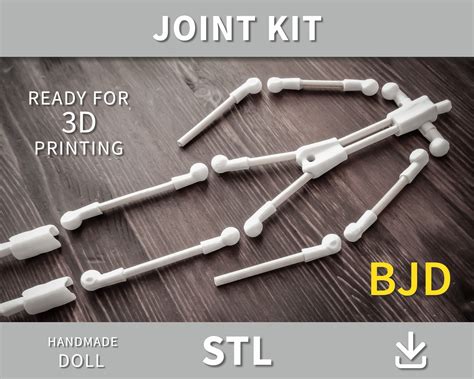

Printing 3D Printable BJDs

Once you've designed your 3D printed BJD, it's time to print it. This involves selecting the right printing material, setting up your printer, and monitoring the printing process. Some popular printing materials for 3D printed BJDs include: * PLA: A biodegradable and eco-friendly material that is easy to print with. * ABS: A strong and durable material that is ideal for creating detailed and intricate designs. * Resin: A high-resolution material that is perfect for creating small and delicate parts.Post-Printing Processing

Tips and Tricks

Here are some additional tips and tricks for working with 3D printed BJDs: * Join online communities: Joining online communities can help you connect with other enthusiasts, share designs, and learn new techniques. * Experiment with different materials: Don't be afraid to experiment with different printing materials and techniques to achieve unique effects. * Keep it fun: Most importantly, remember to keep it fun and enjoy the process of creating and customizing your 3D printed BJDs.Common Challenges

Overcoming Challenges

To overcome these challenges, it's essential to be patient, persistent, and willing to learn. Here are some tips for overcoming common challenges: * Research and troubleshooting: Research and troubleshoot printing errors to identify the cause and find a solution. * Practice and experimentation: Practice and experiment with different printing materials, techniques, and designs to achieve the desired results. * Seek community support: Seek support from online communities and forums to connect with other enthusiasts and learn from their experiences.Gallery of 3D Printable BJDs

3D Printable BJDs Image Gallery

Frequently Asked Questions

What is a 3D printable BJD?

+A 3D printable BJD is a Ball-Jointed Doll that is designed and printed using 3D printing technology.

What are the benefits of 3D printed BJDs?

+The benefits of 3D printed BJDs include customization options, cost-effectiveness, and community involvement.

How do I design a 3D printable BJD?

+To design a 3D printable BJD, you'll need to use 3D modeling software and consider factors such as joint mobility, proportion, and aesthetics.

What are some common challenges when working with 3D printed BJDs?

+Common challenges when working with 3D printed BJDs include printing errors, joint mobility issues, and achieving a smooth and even finish.

How can I overcome common challenges when working with 3D printed BJDs?

+To overcome common challenges, it's essential to be patient, persistent, and willing to learn. Research and troubleshooting, practice and experimentation, and seeking community support can also help.

In conclusion, 3D printable BJDs offer a unique and exciting opportunity for hobbyists and collectors to create and customize their own dolls. With the right knowledge, skills, and techniques, you can overcome common challenges and achieve professional-looking results. Whether you're a seasoned collector or just starting out, we hope this article has provided you with valuable insights and tips for working with 3D printed BJDs. Don't hesitate to share your experiences, ask questions, or showcase your creations in the comments below. Happy crafting!