Intro

Boost labeling efficiency with 5 Uline label tips, including organization, design, and application techniques, to optimize warehouse management, inventory control, and shipping processes.

The world of labeling and organization is a vast and complex one, with numerous tools and techniques available to help individuals and businesses keep their belongings and operations in order. Among the many options available, Uline labels have emerged as a popular choice for those seeking a reliable and efficient labeling solution. In this article, we will delve into the world of Uline labels, exploring their benefits, uses, and best practices for implementation.

Uline labels have become a staple in many industries, from shipping and logistics to retail and healthcare. Their versatility, durability, and ease of use have made them a go-to choice for organizations seeking to streamline their labeling processes. Whether you're looking to label packages, products, or equipment, Uline labels offer a range of benefits that can help you achieve your goals. From improving accuracy and efficiency to enhancing customer satisfaction and reducing costs, the advantages of using Uline labels are numerous and significant.

As we explore the world of Uline labels, it's essential to consider the various ways in which they can be used. From simple labeling tasks to complex organizational projects, Uline labels offer a range of possibilities for individuals and businesses seeking to improve their operations. Whether you're looking to label files, folders, or equipment, or seeking to create a comprehensive labeling system for your organization, Uline labels provide a reliable and efficient solution. With their ease of use, durability, and versatility, it's no wonder that Uline labels have become a popular choice for those seeking to streamline their labeling processes.

Understanding Uline Labels

Benefits of Uline Labels

The benefits of using Uline labels are numerous and significant. Some of the most notable advantages include: * Improved accuracy and efficiency: Uline labels provide a quick and easy way to label packages, products, and equipment, reducing the risk of errors and improving overall efficiency. * Enhanced customer satisfaction: With Uline labels, individuals and businesses can provide clear and accurate labeling, enhancing customer satisfaction and reducing the risk of misunderstandings. * Reduced costs: Uline labels are a cost-effective labeling solution, providing a range of benefits at a lower cost than traditional labeling methods. * Increased productivity: With Uline labels, individuals and businesses can streamline their labeling processes, freeing up time and resources for more important tasks.Uline Label Tips and Tricks

Common Uline Label Mistakes

While Uline labels are a reliable and efficient labeling solution, there are a few common mistakes to avoid. Some of the most notable include: * Using the wrong label size or shape: Using the wrong label size or shape can lead to inaccurate or inefficient labeling, reducing the effectiveness of your Uline labels. * Failing to follow proper labeling procedures: Failing to follow proper labeling procedures can lead to non-compliance with regulations and industry standards, reducing the effectiveness of your Uline labels. * Not testing your labels: Failing to test your Uline labels can lead to inaccurate or inefficient labeling, reducing the effectiveness of your labeling solution.Uline Label Best Practices

Uline Label Troubleshooting

While Uline labels are a reliable and efficient labeling solution, there may be times when issues arise. Some common issues include: * Labels not printing correctly: If your Uline labels are not printing correctly, it may be due to a problem with your label printer or applicator. * Labels not adhering properly: If your Uline labels are not adhering properly, it may be due to a problem with the label material or the surface to which they are being applied. * Labels not scanning correctly: If your Uline labels are not scanning correctly, it may be due to a problem with the label format or content.Uline Label Applications

Uline Label Materials

Uline labels are available in a range of materials, each with its own unique benefits and characteristics. Some of the most notable include: * Paper labels: Paper labels are a cost-effective and versatile labeling solution, suitable for a range of applications. * Plastic labels: Plastic labels are a durable and long-lasting labeling solution, suitable for applications where labels will be exposed to harsh environments. * Vinyl labels: Vinyl labels are a flexible and versatile labeling solution, suitable for applications where labels will be exposed to moisture or extreme temperatures.Uline Label Printing

Uline Label Design

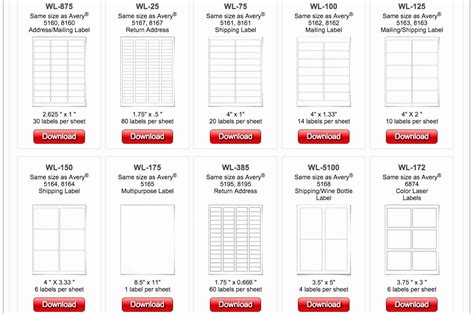

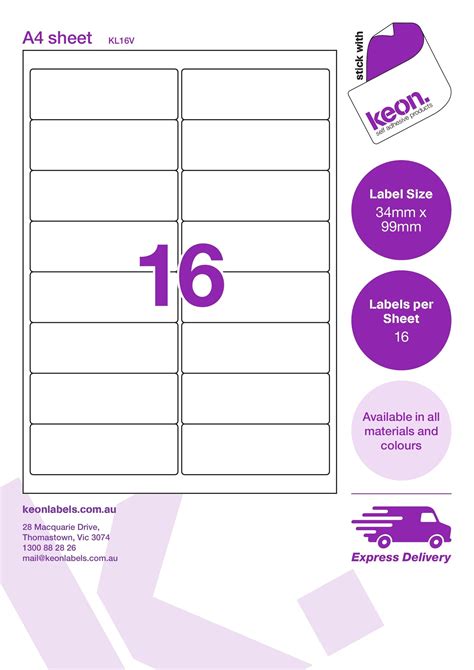

The design of your Uline labels is critical to their effectiveness. Some of the most notable considerations include: * Label size and shape: The size and shape of your Uline labels will depend on the specific application and the equipment or surface to which they will be applied. * Label format and content: The format and content of your Uline labels will depend on the specific application and the regulations and industry standards that apply. * Label material and color: The material and color of your Uline labels will depend on the specific application and the environment in which they will be used.Uline Label Image Gallery

What are Uline labels used for?

+Uline labels are used for a range of applications, from shipping and logistics to retail and healthcare. They provide clear and accurate labeling for packages, products, and equipment.

What are the benefits of using Uline labels?

+The benefits of using Uline labels include improved accuracy and efficiency, enhanced customer satisfaction, reduced costs, and increased productivity.

How do I choose the right Uline label for my needs?

+To choose the right Uline label for your needs, consider the specific application, the equipment or surface to which the label will be applied, and the regulations and industry standards that apply.

Can I print my own Uline labels?

+Yes, you can print your own Uline labels using a range of methods, from thermal transfer printing to inkjet printing.

What is the best way to apply Uline labels?

+The best way to apply Uline labels will depend on the specific application and the equipment or surface to which the label will be applied. It's essential to follow proper labeling procedures to ensure accurate and efficient labeling.

In conclusion, Uline labels are a reliable and efficient labeling solution that can help individuals and businesses improve their operations. By following the tips and best practices outlined in this article, you can get the most out of your Uline labels and achieve your labeling goals. Whether you're looking to label packages, products, or equipment, Uline labels provide a range of benefits that can help you streamline your labeling processes and improve overall efficiency. We invite you to share your experiences with Uline labels and provide feedback on this article. Your input will help us improve our content and provide more valuable information to our readers.