Intro

Boost truck safety with 5 essential inspection tips, including vehicle maintenance, pre-trip checks, and driver training, to prevent accidents and ensure regulatory compliance.

Regular truck inspections are crucial for ensuring the safety and efficiency of trucks on the road. A well-maintained truck not only reduces the risk of accidents but also helps in preventing breakdowns, which can lead to significant delays and costs. Moreover, inspections play a vital role in complying with regulatory requirements, thereby avoiding potential fines and penalties. Given the importance of these inspections, it's essential to approach them with a comprehensive and systematic mindset.

Truck inspections involve a thorough examination of various components and systems to identify any signs of wear, damage, or malfunction. This process requires a combination of technical knowledge and attention to detail. Overlooking critical areas or failing to address issues promptly can have serious consequences, including increased maintenance costs, decreased vehicle performance, and compromised safety. Therefore, understanding the key aspects of truck inspections is vital for fleet managers, drivers, and maintenance personnel.

The process of inspecting a truck can seem daunting, especially for those new to the task. However, breaking it down into manageable steps and focusing on high-priority areas can make the process more efficient and effective. It's also important to leverage technology and resources available, such as inspection checklists and maintenance software, to streamline the process and ensure that no critical component is overlooked. By adopting a proactive approach to truck inspections, operators can significantly improve their fleet's reliability, reduce downtime, and enhance overall safety.

Pre-Trip Inspection Essentials

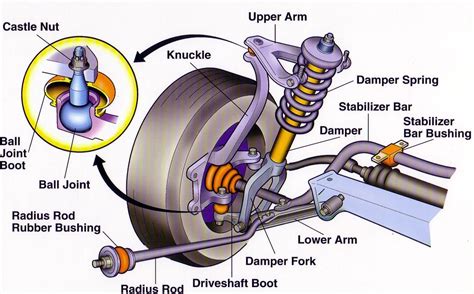

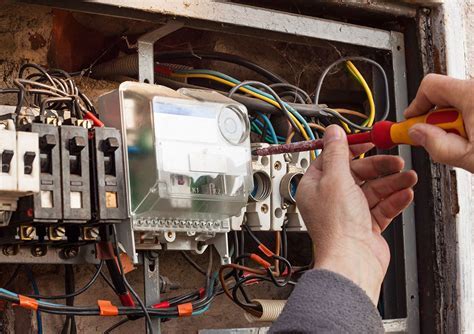

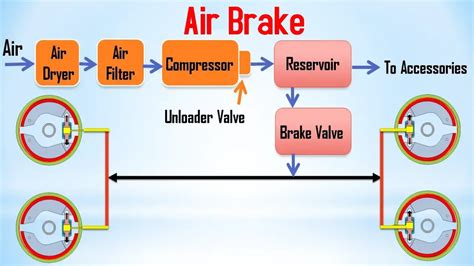

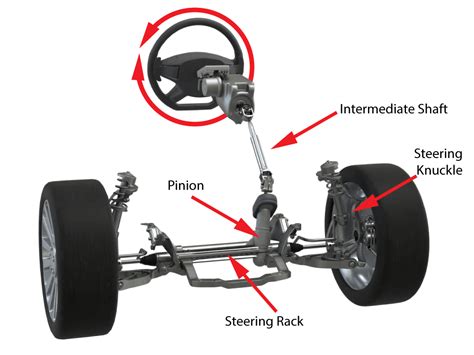

Pre-trip inspections are a critical component of truck safety and maintenance. These inspections are conducted before the truck embarks on a journey to ensure that it is roadworthy and compliant with all regulatory requirements. A key aspect of pre-trip inspections is the review of critical systems such as brakes, tires, and lighting. Drivers should also check for any signs of leaks, damage to the body and chassis, and ensure that all necessary documents and equipment are on board.

Key Components to Inspect

When performing a pre-trip inspection, it's essential to have a systematic approach to ensure that all critical components are examined. This includes: - **Tires:** Checking tread depth, looking for signs of uneven wear, and ensuring proper inflation. - **Brakes:** Inspecting brake pads, checking for leaks in the brake system, and testing brake performance. - **Lights and Reflectors:** Ensuring all lights, including headlights, taillights, and brake lights, are functioning properly, and that reflectors are clean and intact. - **Coupling Devices:** For combination vehicles, inspecting the condition and security of the coupling devices.Regular Maintenance Scheduling

Regular maintenance is the backbone of any effective truck inspection and maintenance program. It involves scheduling inspections and repairs at regular intervals, based on factors such as mileage, time, and usage patterns. This proactive approach helps in identifying and addressing potential issues before they become major problems. Regular maintenance also includes tasks such as oil changes, filter replacements, and adjustments to brakes and other systems.

Benefits of Scheduled Maintenance

The benefits of regular, scheduled maintenance are numerous and significant. They include: - **Reduced Breakdowns:** Regular checks and maintenance can identify and fix issues before they lead to breakdowns. - **Improved Safety:** By ensuring that all systems are functioning properly, scheduled maintenance enhances safety for the driver and other road users. - **Cost Savings:** Preventive maintenance can reduce repair costs in the long run by addressing issues early and preventing more severe problems from developing. - **Compliance:** Regular maintenance helps in complying with regulatory requirements, thereby avoiding fines and penalties.Technological Advancements in Truck Inspections

The advent of technology has significantly impacted the field of truck inspections, making the process more efficient, accurate, and comprehensive. Digital inspection tools and software allow for the creation of detailed, customizable inspection checklists, facilitate real-time reporting of defects, and enable the tracking of maintenance history. Additionally, technologies such as telematics and vehicle diagnostics provide valuable insights into vehicle performance and health, helping in the early detection of potential issues.

Integration of Technology

The integration of technology into truck inspection processes offers several advantages, including: - **Enhanced Accuracy:** Digital tools reduce the likelihood of human error, ensuring that inspections are thorough and accurate. - **Increased Efficiency:** Automated processes and real-time data access streamline inspections, reducing downtime and increasing productivity. - **Data-Driven Decisions:** The ability to analyze vehicle performance and maintenance data enables more informed decision-making regarding fleet management and maintenance scheduling.Driver Training and Awareness

Driver training and awareness are critical components of an effective truck inspection program. Drivers are often the first line of defense in identifying issues with the vehicle, as they are most familiar with its performance and any changes in its condition. Therefore, providing drivers with comprehensive training on how to conduct inspections, recognize potential problems, and report defects is essential.

Training Programs

Effective driver training programs should cover: - **Inspection Procedures:** Detailed guidance on how to perform pre-trip, en-route, and post-trip inspections. - **Defect Recognition:** Training on identifying common defects and understanding their implications for safety and compliance. - **Reporting and Follow-Up:** Procedures for reporting defects and ensuring that necessary repairs are made promptly.Regulatory Compliance and Standards

Regulatory compliance is a fundamental aspect of truck inspections, as non-compliance can result in severe penalties, fines, and even the suspension of operating authority. Regulatory bodies such as the Federal Motor Carrier Safety Administration (FMCSA) in the United States set standards for vehicle maintenance, inspection, and operation. Understanding and adhering to these regulations is crucial for fleet operators.

Key Regulations

Some of the key regulations and standards that truck operators must comply with include: - **Vehicle Inspection Regulations:** Requirements for the frequency and scope of vehicle inspections. - **Maintenance Standards:** Specifications for vehicle maintenance, including requirements for parts, repairs, and inspections. - **Driver Qualification Files:** Regulations regarding the maintenance of driver qualification files, including training, licensing, and medical certification.Gallery of Truck Inspection Images

Truck Inspection Image Gallery

What is the importance of regular truck inspections?

+Regular truck inspections are crucial for ensuring safety, preventing breakdowns, and complying with regulatory requirements. They help in identifying and addressing potential issues before they become major problems, thereby reducing maintenance costs, enhancing safety, and avoiding fines and penalties.

How often should truck inspections be conducted?

+The frequency of truck inspections can vary based on factors such as mileage, time, and usage patterns. Generally, pre-trip inspections are conducted before each trip, while regular maintenance inspections are scheduled at intervals specified by the manufacturer or regulatory bodies.

What are the key components to inspect during a truck inspection?

+Key components to inspect include tires, brakes, lighting and reflectors, coupling devices, and the vehicle's body and chassis. Additionally, inspections should cover critical systems such as the engine, transmission, and electrical systems.

In conclusion, truck inspections are a vital aspect of fleet management, playing a critical role in ensuring safety, efficiency, and compliance. By understanding the importance of inspections, leveraging technology, and adopting a proactive maintenance approach, fleet operators can significantly enhance their operations. Whether you're a seasoned fleet manager or just starting out, prioritizing truck inspections is key to achieving your operational goals and maintaining a safe, reliable fleet. We invite you to share your thoughts and experiences with truck inspections, and to explore further how these practices can benefit your operations. Your feedback and insights are invaluable in our ongoing effort to provide the most relevant and useful information to our readers.