Intro

Discover how heat transfer sheets work with 5 innovative methods, utilizing thermal printing, sublimation, and conduction techniques for efficient heat transfer, perfect for custom designs and textiles.

Heat transfer sheets have become an essential tool in various industries, including fashion, sports, and advertising. These sheets allow for the easy application of designs, logos, and text onto different materials, such as fabrics, plastics, and metals. The process of heat transfer involves the use of heat and pressure to transfer the design from the sheet onto the desired material. In this article, we will explore the five ways heat transfer sheets work and their applications.

The importance of heat transfer sheets lies in their ability to provide a quick and efficient way to customize various products. With the rise of personalization and branding, businesses and individuals are looking for ways to stand out from the crowd. Heat transfer sheets offer a cost-effective and versatile solution for achieving this goal. Whether it's creating custom t-shirts, signage, or promotional products, heat transfer sheets have become an indispensable tool.

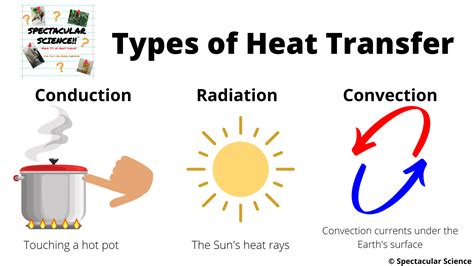

The process of heat transfer is based on the principle of sublimation, where the ink on the sheet turns into a gas when heated, allowing it to penetrate the material and create a permanent bond. This process requires a combination of heat, pressure, and time to ensure a successful transfer. The type of material being used, the design itself, and the equipment available will all impact the outcome of the heat transfer process. Understanding how heat transfer sheets work is crucial for achieving professional-looking results and ensuring the durability of the design.

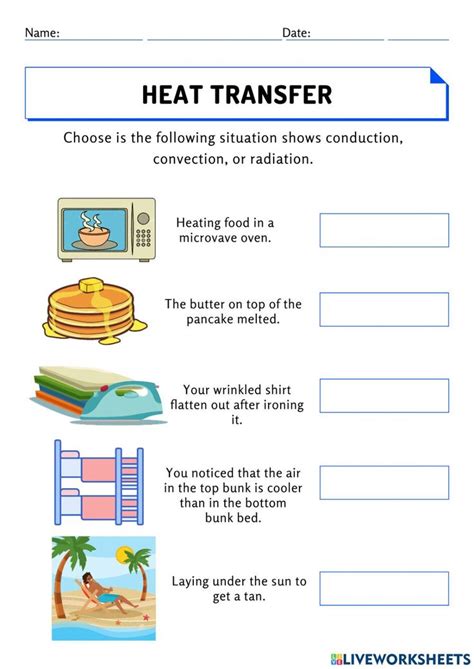

Introduction to Heat Transfer Sheets

Heat transfer sheets are a type of paper or film coated with a heat-activated adhesive and ink. The sheets are designed to be used with a heat press, which applies the necessary heat and pressure to transfer the design onto the material. The sheets come in various sizes, shapes, and colors, making them suitable for a wide range of applications. From custom apparel to signage and packaging, heat transfer sheets have become a popular choice for businesses and individuals looking to create professional-looking products.

How Heat Transfer Sheets Work

The process of heat transfer involves several key steps. First, the design is printed onto the heat transfer sheet using a special ink that is designed to sublimate when heated. The sheet is then placed onto the material, and the heat press is applied. The heat press applies a combination of heat and pressure, causing the ink to sublimate and penetrate the material. The pressure ensures that the design is evenly applied and that the ink is fully transferred. The result is a permanent bond between the design and the material.

Key Factors Affecting Heat Transfer

Several factors can affect the outcome of the heat transfer process. These include:

- The type of material being used: Different materials require different temperatures, pressures, and times to achieve a successful transfer.

- The design itself: The complexity and size of the design will impact the transfer process.

- The equipment available: The type and quality of the heat press, as well as the heat transfer sheet, will affect the outcome.

- The temperature and pressure: The correct temperature and pressure must be applied to ensure a successful transfer.

Applications of Heat Transfer Sheets

Heat transfer sheets have a wide range of applications across various industries. Some of the most common uses include:

- Custom apparel: Heat transfer sheets are used to create custom t-shirts, hoodies, and other clothing items.

- Signage: Heat transfer sheets are used to create custom signs, banners, and decals.

- Packaging: Heat transfer sheets are used to create custom packaging, including labels and stickers.

- Promotional products: Heat transfer sheets are used to create custom promotional products, such as water bottles, mugs, and phone cases.

Benefits of Heat Transfer Sheets

Heat transfer sheets offer several benefits, including:

- Cost-effectiveness: Heat transfer sheets are a cost-effective way to customize products.

- Versatility: Heat transfer sheets can be used on a wide range of materials.

- Durability: The designs created with heat transfer sheets are permanent and long-lasting.

- Ease of use: Heat transfer sheets are easy to use, requiring minimal equipment and training.

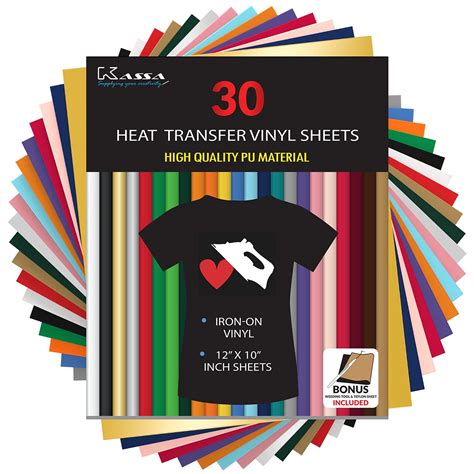

Types of Heat Transfer Sheets

There are several types of heat transfer sheets available, each with its own unique characteristics and applications. Some of the most common types include:

- Vinyl heat transfer sheets: These sheets are made from a flexible vinyl material and are suitable for use on fabrics, plastics, and metals.

- Polyester heat transfer sheets: These sheets are made from a durable polyester material and are suitable for use on fabrics, plastics, and metals.

- Cotton heat transfer sheets: These sheets are made from a cotton material and are suitable for use on fabrics, particularly cotton and cotton blends.

Choosing the Right Heat Transfer Sheet

Choosing the right heat transfer sheet depends on the specific application and material being used. Factors to consider include:

- The type of material: Different materials require different types of heat transfer sheets.

- The design: The complexity and size of the design will impact the choice of heat transfer sheet.

- The equipment available: The type and quality of the heat press will affect the choice of heat transfer sheet.

Best Practices for Using Heat Transfer Sheets

To achieve professional-looking results with heat transfer sheets, it's essential to follow best practices. These include:

- Using high-quality heat transfer sheets and equipment.

- Following the manufacturer's instructions for temperature, pressure, and time.

- Testing the heat transfer sheet on a small area before applying it to the final product.

- Using a heat press with a digital temperature control to ensure accurate temperature settings.

Troubleshooting Common Issues

Common issues that can arise when using heat transfer sheets include:

- Incomplete transfer: This can be caused by insufficient heat, pressure, or time.

- Peeling or flaking: This can be caused by using the wrong type of heat transfer sheet or equipment.

- Color fading: This can be caused by using low-quality heat transfer sheets or equipment.

Heat Transfer Sheets Image Gallery

What is the best type of heat transfer sheet for custom apparel?

+The best type of heat transfer sheet for custom apparel depends on the type of fabric being used. For cotton and cotton blends, a cotton heat transfer sheet is recommended. For polyester and polyester blends, a polyester heat transfer sheet is recommended.

How do I choose the right heat press for my heat transfer sheets?

+When choosing a heat press, consider the size and type of heat transfer sheets you will be using. A heat press with a digital temperature control and a large platens is recommended for large and complex designs.

What is the difference between vinyl and polyester heat transfer sheets?

+Vinyl heat transfer sheets are made from a flexible vinyl material and are suitable for use on fabrics, plastics, and metals. Polyester heat transfer sheets are made from a durable polyester material and are suitable for use on fabrics, plastics, and metals. The choice between vinyl and polyester heat transfer sheets depends on the specific application and material being used.

In conclusion, heat transfer sheets are a versatile and cost-effective way to customize various products. By understanding how heat transfer sheets work and following best practices, businesses and individuals can achieve professional-looking results and create high-quality products. Whether it's custom apparel, signage, packaging, or promotional products, heat transfer sheets have become an essential tool in various industries. We invite you to share your experiences and tips for using heat transfer sheets in the comments below. Additionally, if you have any questions or need further guidance, don't hesitate to reach out.