Intro

Boost label printing with 5 expert tips, covering label design, material selection, and printer settings, for high-quality stickers, tags, and decals, using techniques like die-cutting and laminating.

The importance of label printing cannot be overstated, as it plays a crucial role in various industries such as packaging, shipping, and marketing. Labels are used to convey vital information about a product, provide instructions, and create brand awareness. With the advancement of technology, label printing has become more efficient and cost-effective. However, to achieve high-quality labels, it is essential to follow certain tips and best practices. In this article, we will explore five label printing tips that can help you produce professional-looking labels that meet your needs.

Label printing is a complex process that involves several factors, including the type of label, printing technology, and design. Whether you are printing labels for a small business or a large corporation, it is crucial to understand the basics of label printing to avoid common mistakes. One of the most significant advantages of label printing is its versatility, as it can be used for various applications, including product labeling, shipping labels, and marketing materials. By following the right tips and techniques, you can create labels that are not only visually appealing but also durable and long-lasting.

The benefits of label printing are numerous, and it is an essential aspect of any business that requires labeling. From food packaging to pharmaceuticals, labels play a critical role in providing vital information about a product. With the rise of e-commerce, label printing has become even more important, as it helps to ensure that products are shipped correctly and efficiently. Moreover, labels can be used to create brand awareness and differentiate a product from its competitors. By investing in high-quality label printing, businesses can improve their overall brand image and increase customer satisfaction.

Understanding Label Printing Basics

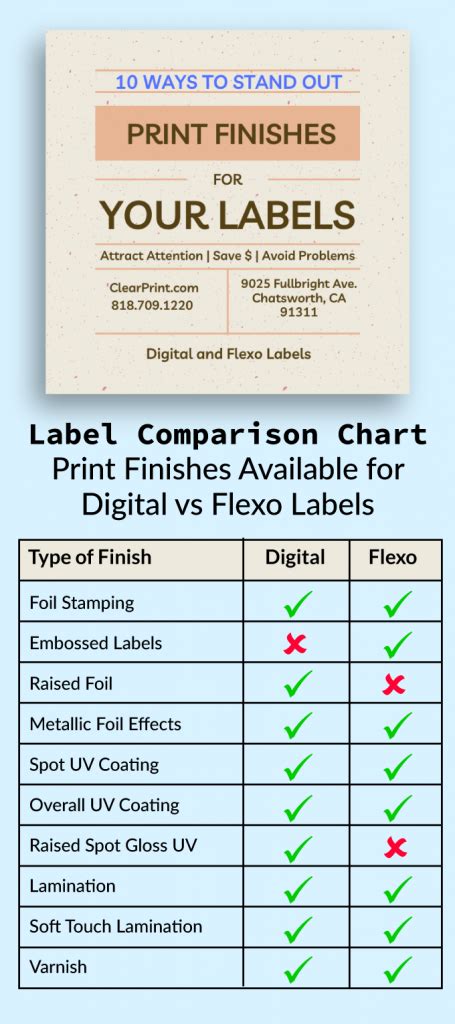

Before we dive into the tips, it is essential to understand the basics of label printing. Label printing involves several factors, including the type of label, printing technology, and design. There are various types of labels, including paper labels, vinyl labels, and foil labels, each with its unique characteristics and advantages. The printing technology used can also vary, including inkjet, laser, and flexographic printing. Understanding the basics of label printing is crucial to produce high-quality labels that meet your needs.

Choosing the Right Label Material

Choosing the right label material is critical to ensure that your labels are durable and long-lasting. The type of material used can vary depending on the application, including paper, vinyl, and foil. Paper labels are the most common type of label and are suitable for most applications. Vinyl labels, on the other hand, are more durable and resistant to water and chemicals. Foil labels are often used for high-end products and can add a touch of luxury to your packaging.

Factors to Consider When Choosing Label Material

When choosing a label material, there are several factors to consider, including: * Durability: How long do you want your labels to last? * Adhesive: What type of adhesive do you need? * Environment: Will your labels be exposed to water, chemicals, or extreme temperatures? * Aesthetics: What color and finish do you want your labels to have?Designing Effective Labels

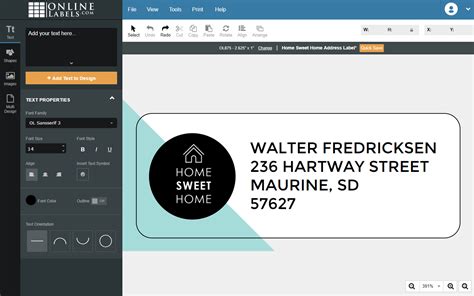

Designing effective labels is crucial to convey the right message and create brand awareness. A well-designed label can help to differentiate your product from its competitors and create a lasting impression on your customers. When designing labels, it is essential to consider several factors, including the size, shape, color, and font. The label should be easy to read and understand, and the design should be consistent with your brand image.

Best Practices for Label Design

When designing labels, there are several best practices to follow, including: * Keep it simple: Avoid clutter and keep your design simple and concise. * Use high-quality images: Use high-quality images that are relevant to your product or brand. * Choose the right font: Choose a font that is easy to read and consistent with your brand image. * Use color effectively: Use color to create contrast and make your label stand out.Printing Labels with High-Quality Images

Printing labels with high-quality images is essential to create a professional-looking label. The quality of the image can vary depending on the printing technology used, including inkjet, laser, and flexographic printing. Inkjet printing is suitable for most applications and can produce high-quality images with vibrant colors. Laser printing, on the other hand, is more suitable for high-volume printing and can produce high-quality text and images.

Tips for Printing High-Quality Labels

When printing labels, there are several tips to follow, including: * Use high-quality paper: Use high-quality paper that is suitable for label printing. * Adjust the print settings: Adjust the print settings to ensure that your labels are printed with high-quality images. * Use the right ink: Use the right ink that is suitable for your printing technology.Label Finishing and Lamination

Label finishing and lamination are essential to protect your labels from damage and extend their lifespan. Label finishing involves several processes, including cutting, trimming, and folding. Lamination, on the other hand, involves applying a thin layer of plastic to the label to protect it from water, chemicals, and extreme temperatures.

Benefits of Label Finishing and Lamination

Label finishing and lamination offer several benefits, including: * Durability: Labels are more resistant to damage and can last longer. * Protection: Labels are protected from water, chemicals, and extreme temperatures. * Aesthetics: Labels can have a glossy or matte finish, depending on the lamination used.Label Printing Image Gallery

What is the best label material for outdoor use?

+Vinyl labels are the best option for outdoor use, as they are durable and resistant to water and chemicals.

How do I design effective labels?

+To design effective labels, keep it simple, use high-quality images, choose the right font, and use color effectively.

What is the difference between inkjet and laser printing?

+Inkjet printing is suitable for most applications and can produce high-quality images with vibrant colors, while laser printing is more suitable for high-volume printing and can produce high-quality text and images.

Do I need to laminate my labels?

+Yes, lamination can protect your labels from damage and extend their lifespan, making them more durable and resistant to water, chemicals, and extreme temperatures.

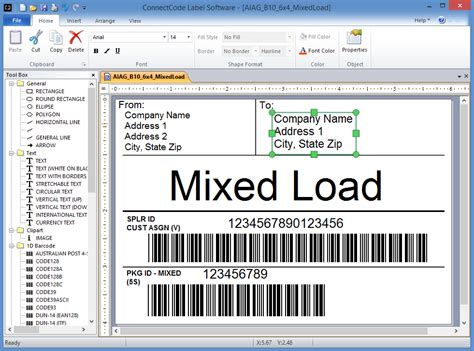

What is the best label printing software?

+The best label printing software depends on your specific needs and requirements, but popular options include Adobe Illustrator, CorelDRAW, and LabelWorks.

In conclusion, label printing is a complex process that requires careful consideration of several factors, including the type of label, printing technology, and design. By following the five label printing tips outlined in this article, you can produce high-quality labels that meet your needs and create a professional image for your business. Remember to choose the right label material, design effective labels, print labels with high-quality images, finish and laminate your labels, and use the right label printing software. With these tips and best practices, you can create labels that are not only visually appealing but also durable and long-lasting. We hope you found this article informative and helpful. If you have any questions or comments, please feel free to share them with us.