Intro

Discover 5 Spectra Flange Sizes, including dimensions, types, and applications, to enhance pipe fittings, tubing, and plumbing systems with precision engineering and leak-free connections.

The importance of understanding Spectra flange sizes cannot be overstated, particularly in industries where precision and accuracy are paramount. Spectra, a leading manufacturer of high-quality piping components, offers a range of flange sizes to cater to diverse application requirements. Flanges are essential components in piping systems, serving as connectors for pipes, valves, pumps, and other equipment. They ensure the integrity and safety of the system by providing a secure and leak-tight connection. In this article, we will delve into the specifics of Spectra flange sizes, exploring their dimensions, applications, and the factors to consider when selecting the appropriate flange size for a particular project.

The selection of the correct flange size is crucial for the efficient operation of a piping system. Incorrect flange sizing can lead to leaks, reduced system performance, and potentially catastrophic failures. Therefore, it is essential to have a comprehensive understanding of the available Spectra flange sizes and their corresponding applications. Spectra flanges are designed to meet or exceed industry standards, ensuring reliability and durability in demanding environments. By choosing the right flange size, engineers and technicians can ensure the optimal performance of their piping systems, minimize downtime, and reduce maintenance costs.

Spectra flanges are available in a variety of sizes, ranging from small diameters for low-pressure applications to large diameters for high-pressure and high-temperature applications. Each flange size is carefully engineered to meet specific performance criteria, taking into account factors such as pressure rating, material compatibility, and corrosion resistance. Whether it's for a chemical processing plant, an oil refinery, or a power generation facility, Spectra offers a flange size that can meet the unique demands of the application. In the following sections, we will explore the different Spectra flange sizes, their characteristics, and the considerations for selecting the most suitable flange for a given project.

Introduction to Spectra Flange Sizes

Understanding Flange Dimensions

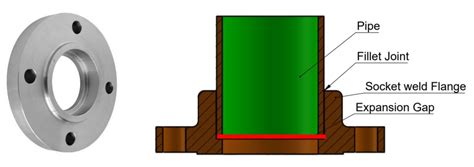

To appreciate the significance of Spectra flange sizes, it's essential to understand the various dimensions that define a flange. These include: - Outside diameter: The diameter of the flange, measured across its outer edges. - Inside diameter: The diameter of the bore, which corresponds to the inside diameter of the pipe. - Thickness: The thickness of the flange, which affects its strength and durability. - Bolt circle diameter: The diameter of the circle on which the bolt holes are evenly spaced. - Bolt hole diameter: The diameter of the holes for the bolts that secure the flange to the piping component.Applications of Spectra Flange Sizes

Material Selection

The material of the flange is another critical factor, as it must be compatible with the fluid being transported and the operating conditions of the system. Spectra offers flanges in various materials, such as: - Stainless steel: For corrosion resistance and high strength. - Carbon steel: For general-purpose applications where cost-effectiveness is a priority. - Exotic alloys: For highly corrosive or extreme temperature environments.Selection Criteria for Spectra Flange Sizes

Standards and Specifications

Spectra flanges are designed to meet or exceed various industry standards and specifications, such as ASME (American Society of Mechanical Engineers), API (American Petroleum Institute), and DIN (Deutsches Institut für Normung). Compliance with these standards ensures that the flanges are manufactured to precise tolerances and can withstand the rigors of demanding applications.Installation and Maintenance of Spectra Flanges

Troubleshooting Common Issues

Common issues with Spectra flanges, such as leaks or corrosion, can often be traced back to improper installation, inadequate maintenance, or the use of incorrect materials. Troubleshooting these issues involves identifying the root cause and taking corrective action, which may include replacing the flange, adjusting the bolt torque, or applying a corrosion-resistant coating.Gallery of Spectra Flange Sizes

Spectra Flange Image Gallery

Frequently Asked Questions

What are the most common Spectra flange sizes?

+The most common Spectra flange sizes range from 1/2 inch to 24 inches, with larger sizes available for specialized applications.

How do I select the right Spectra flange size for my application?

+Consider factors such as pressure rating, temperature rating, material compatibility, and corrosion resistance to select the most suitable Spectra flange size for your application.

What materials are Spectra flanges available in?

+Spectra flanges are available in various materials, including stainless steel, carbon steel, and exotic alloys, to meet different application requirements.

In conclusion, understanding Spectra flange sizes is crucial for the successful design, installation, and operation of piping systems across various industries. By considering the factors outlined in this article and selecting the appropriate flange size, engineers and technicians can ensure the reliability, safety, and efficiency of their systems. We invite readers to share their experiences with Spectra flanges and to ask any questions they may have regarding the selection and application of these critical components. Whether you are involved in the design, procurement, or maintenance of piping systems, the information provided here aims to serve as a valuable resource in your work with Spectra flanges.