Intro

Unlock efficiency with 5 Ways VSM Template, streamlining value stream mapping, process optimization, and lean manufacturing, boosting productivity and reducing waste.

The importance of effective visualization and management tools cannot be overstated in today's fast-paced business environment. One such tool that has gained popularity is the VSM (Value Stream Mapping) template. VSM is a lean management method used to analyze and improve the flow of materials and information within a process. It helps organizations identify waste, optimize processes, and improve overall efficiency. In this article, we will explore five ways a VSM template can benefit your organization and provide a comprehensive guide on how to implement it.

The use of VSM templates has become increasingly widespread across various industries, from manufacturing to healthcare. This is due to its ability to provide a clear and concise visual representation of complex processes, making it easier to identify areas for improvement. By utilizing a VSM template, organizations can streamline their operations, reduce waste, and improve customer satisfaction. Whether you are a seasoned lean practitioner or just starting to explore the world of process improvement, this article will provide you with valuable insights into the benefits and applications of VSM templates.

In today's competitive business landscape, organizations must continually strive to improve their processes and stay ahead of the curve. The VSM template offers a powerful tool for achieving this goal. By providing a structured approach to process analysis and improvement, it enables organizations to identify and eliminate waste, optimize workflows, and improve overall efficiency. In the following sections, we will delve deeper into the benefits and applications of VSM templates, exploring five key ways they can benefit your organization.

Introduction to VSM Templates

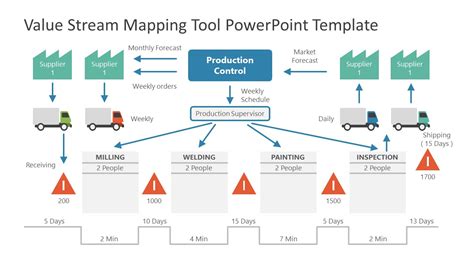

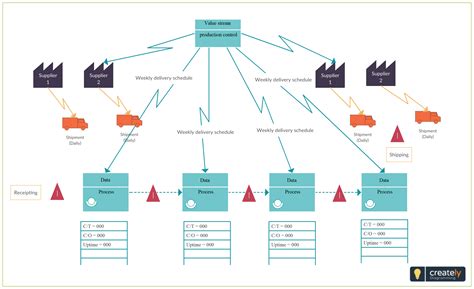

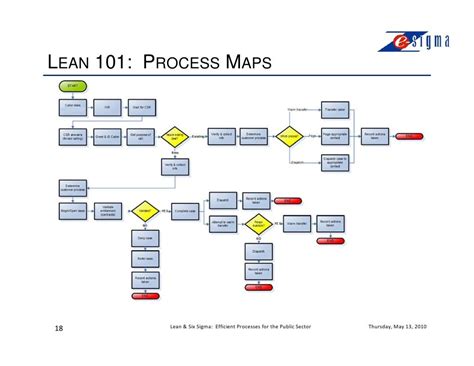

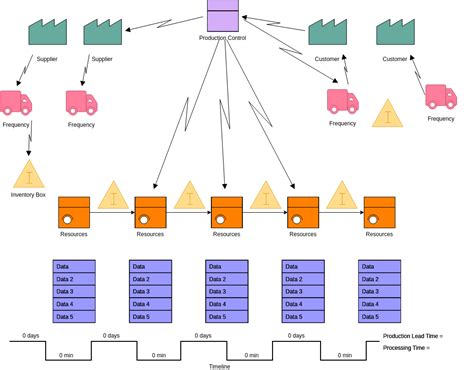

A VSM template is a visual representation of a process or system, used to identify and analyze the flow of materials and information. It is typically created using a combination of symbols, diagrams, and charts to illustrate the various stages of a process, from raw materials to delivery of the final product. The template is designed to provide a clear and concise overview of the process, making it easier to identify areas for improvement.

Benefits of Using VSM Templates

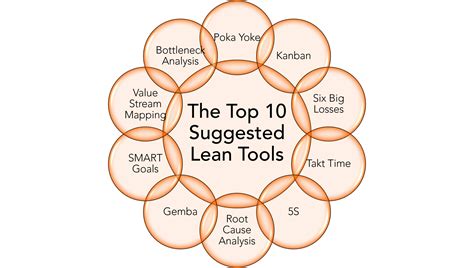

The benefits of using VSM templates are numerous. Some of the key advantages include:

- Improved process efficiency: By identifying and eliminating waste, organizations can streamline their operations and improve overall efficiency.

- Enhanced customer satisfaction: By optimizing processes and reducing waste, organizations can improve the quality and delivery of their products or services, leading to increased customer satisfaction.

- Increased productivity: By streamlining processes and eliminating waste, organizations can free up resources and improve productivity.

- Reduced costs: By identifying and eliminating waste, organizations can reduce costs and improve profitability.

- Improved communication: VSM templates provide a clear and concise visual representation of complex processes, making it easier for teams to communicate and collaborate.

5 Ways to Use VSM Templates

There are several ways to use VSM templates, depending on the specific needs and goals of your organization. Here are five key ways to utilize VSM templates:

- Process analysis: Use VSM templates to analyze and map out complex processes, identifying areas for improvement and opportunities to eliminate waste.

- Process improvement: Use VSM templates to identify and prioritize areas for improvement, and to develop and implement process improvements.

- Communication and collaboration: Use VSM templates to provide a clear and concise visual representation of complex processes, making it easier for teams to communicate and collaborate.

- Training and education: Use VSM templates to educate and train employees on lean principles and process improvement methodologies.

- Performance measurement: Use VSM templates to measure and track performance, identifying areas for improvement and opportunities to optimize processes.

Implementing VSM Templates in Your Organization

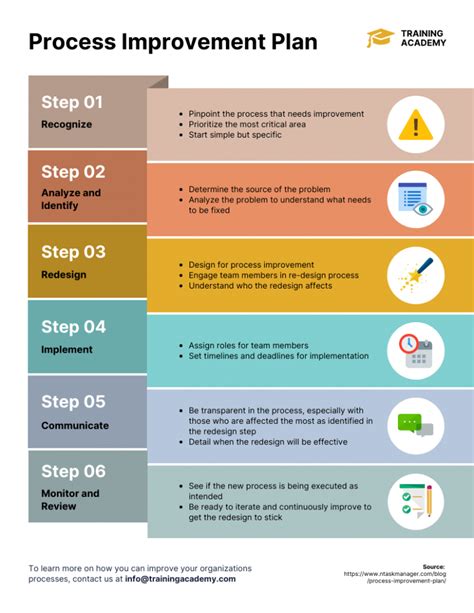

Implementing VSM templates in your organization requires a structured approach. Here are some steps to follow:

- Identify the process or system to be mapped: Determine which process or system to focus on, and gather relevant data and information.

- Gather a cross-functional team: Assemble a team of employees from various departments and levels to participate in the mapping process.

- Create the VSM template: Use a combination of symbols, diagrams, and charts to create a visual representation of the process or system.

- Analyze and identify areas for improvement: Use the VSM template to identify areas for improvement and opportunities to eliminate waste.

- Develop and implement process improvements: Prioritize areas for improvement and develop and implement process improvements.

Best Practices for Using VSM Templates

To get the most out of VSM templates, it's essential to follow best practices. Here are some tips:

- Keep it simple: Avoid using complex symbols or diagrams that may be difficult to understand.

- Focus on the process: Keep the focus on the process or system being mapped, rather than individual tasks or activities.

- Involve the team: Encourage participation and input from employees at all levels and departments.

- Continuously improve: Regularly review and update the VSM template to reflect changes and improvements to the process or system.

Common Challenges and Solutions

When implementing VSM templates, organizations may encounter common challenges. Here are some solutions:

- Resistance to change: Encourage employee participation and input, and provide training and education on lean principles and process improvement methodologies.

- Lack of data: Gather relevant data and information, and use metrics and benchmarks to measure and track performance.

- Limited resources: Prioritize areas for improvement and focus on high-impact changes.

Gallery of VSM Templates

VSM Templates Image Gallery

What is a VSM template?

+A VSM template is a visual representation of a process or system, used to identify and analyze the flow of materials and information.

How do I create a VSM template?

+To create a VSM template, gather relevant data and information, and use a combination of symbols, diagrams, and charts to illustrate the various stages of a process.

What are the benefits of using VSM templates?

+The benefits of using VSM templates include improved process efficiency, enhanced customer satisfaction, increased productivity, reduced costs, and improved communication.

In conclusion, VSM templates offer a powerful tool for process analysis and improvement. By providing a clear and concise visual representation of complex processes, they enable organizations to identify and eliminate waste, optimize workflows, and improve overall efficiency. Whether you are a seasoned lean practitioner or just starting to explore the world of process improvement, this article has provided you with valuable insights into the benefits and applications of VSM templates. We invite you to share your thoughts and experiences with VSM templates in the comments below, and to explore our other resources on lean management and process improvement.