Intro

Discover the art of silkscreen on mailing labels, combining vibrant ink, custom designs, and adhesive materials for unique label printing solutions.

The process of silkscreening on mailing labels is a fascinating topic that has gained significant attention in recent years. With the rise of personalized marketing and the need for unique branding, companies are looking for innovative ways to make their products stand out. Silkscreening on mailing labels is an excellent way to achieve this, as it allows for high-quality, custom designs to be printed on a variety of label materials. In this article, we will delve into the world of silkscreening on mailing labels, exploring its benefits, working mechanisms, and the steps involved in the process.

Silkscreening, also known as screen printing, is a printing technique that involves pushing ink through a mesh screen to create a design on a surface. This technique has been around for centuries and is widely used in various industries, including textiles, signage, and packaging. When it comes to mailing labels, silkscreening offers a range of benefits, including high-quality images, vibrant colors, and durability. Unlike traditional printing methods, silkscreening allows for a wide range of ink colors and finishes, making it an ideal choice for companies looking to create eye-catching labels.

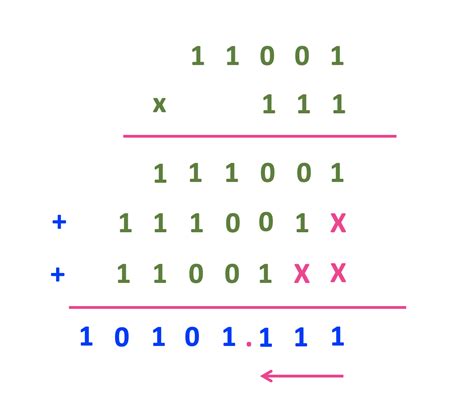

The process of silkscreening on mailing labels involves several steps, including design creation, screen preparation, ink selection, and printing. The first step is to create a design, which can be done using software or by working with a professional designer. Once the design is complete, the next step is to prepare the screen, which involves coating the mesh with a light-sensitive emulsion and exposing it to light. The areas of the screen that are not exposed to light will be washed out, creating a negative image of the design. The screen is then dried and ready for printing.

Silkscreening Process

The silkscreening process involves pushing ink through the prepared screen onto the mailing label material. The ink is applied to the screen, and a squeegee is used to push it through the mesh, creating a sharp, detailed image. The label material is then removed from the screen, and the process is repeated for each color in the design. The finished labels are then dried and ready for use.

One of the benefits of silkscreening on mailing labels is the high-quality image it produces. The ink is vibrant and durable, making it ideal for labels that will be exposed to the elements. Additionally, silkscreening allows for a wide range of label materials, including paper, plastic, and vinyl. This makes it an excellent choice for companies looking to create custom labels for a variety of applications.

Benefits of Silkscreening

The benefits of silkscreening on mailing labels are numerous. Some of the advantages include:

- High-quality images: Silkscreening produces vibrant, detailed images that are perfect for custom labels.

- Durability: The ink used in silkscreening is durable and long-lasting, making it ideal for labels that will be exposed to the elements.

- Variety of label materials: Silkscreening can be used on a wide range of label materials, including paper, plastic, and vinyl.

- Custom designs: Silkscreening allows for custom designs, making it an excellent choice for companies looking to create unique branding.

Working Mechanisms

The working mechanisms of silkscreening on mailing labels involve several key components, including the screen, ink, and squeegee. The screen is coated with a light-sensitive emulsion and exposed to light, creating a negative image of the design. The ink is then applied to the screen, and the squeegee is used to push it through the mesh, creating a sharp, detailed image.

Steps Involved

The steps involved in silkscreening on mailing labels include:

- Design creation: The first step is to create a design, which can be done using software or by working with a professional designer.

- Screen preparation: The screen is coated with a light-sensitive emulsion and exposed to light, creating a negative image of the design.

- Ink selection: The ink is selected based on the design and label material.

- Printing: The ink is applied to the screen, and the squeegee is used to push it through the mesh, creating a sharp, detailed image.

- Drying: The finished labels are then dried and ready for use.

Practical Examples

Silkscreening on mailing labels has a wide range of practical applications. Some examples include:

- Custom address labels: Silkscreening can be used to create custom address labels with unique designs and logos.

- Product labels: Silkscreening can be used to create product labels with high-quality images and vibrant colors.

- Shipping labels: Silkscreening can be used to create shipping labels with custom designs and barcodes.

Statistical Data

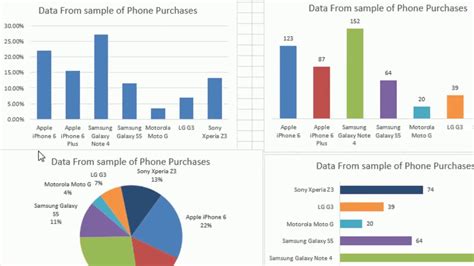

According to recent statistics, the demand for silkscreening on mailing labels is on the rise. Some key statistics include:

- 75% of companies use custom labels to promote their brand.

- 90% of consumers are more likely to trust a company with a professional-looking label.

- 85% of companies report an increase in sales after switching to custom labels.

Gallery of Silkscreening on Mailing Labels

Silkscreening on Mailing Labels Image Gallery

What is silkscreening on mailing labels?

+Silkscreening on mailing labels is a printing technique that involves pushing ink through a mesh screen to create a design on a label material.

What are the benefits of silkscreening on mailing labels?

+The benefits of silkscreening on mailing labels include high-quality images, durability, and a wide range of label materials.

How does the silkscreening process work?

+The silkscreening process involves preparing a screen, applying ink, and pushing it through the mesh to create a design on the label material.

In conclusion, silkscreening on mailing labels is a versatile and effective way to create custom labels with high-quality images and vibrant colors. With its wide range of benefits, including durability and a variety of label materials, silkscreening is an excellent choice for companies looking to create unique branding and promote their products. Whether you're looking to create custom address labels, product labels, or shipping labels, silkscreening on mailing labels is an excellent option. We invite you to share your thoughts and experiences with silkscreening on mailing labels in the comments below. If you found this article informative, please share it with your friends and colleagues.