Intro

Discover the ultimate Printable Sublimation Vinyl Guide, featuring heat transfer techniques, sublimation printing tips, and vinyl application methods for custom designs, DIY projects, and craft ideas.

The world of crafting and DIY projects has experienced a significant surge in popularity over the years, with many individuals seeking unique and personalized items for their homes, gifts, and personal use. One technique that has gained considerable attention is sublimation printing, which allows for the creation of vibrant, full-color designs on various materials. At the heart of this process is printable sublimation vinyl, a versatile and user-friendly material that has opened up new avenues for crafters and small business owners alike. Understanding the ins and outs of printable sublimation vinyl is crucial for anyone looking to dive into this creative and potentially lucrative world.

Sublimation printing itself is a process where sublimation ink is printed onto a material, typically coated with a special polymer, and then heated to transfer the ink into the material, creating a permanent, photo-quality image. Printable sublimation vinyl serves as an intermediary in this process, allowing for the easy transfer of designs onto a wide range of substrates, from ceramics and glass to fabric and wood. The appeal of printable sublimation vinyl lies in its ease of use, flexibility, and the high-quality results it produces, making it an ideal choice for both beginners and experienced crafters.

The importance of printable sublimation vinyl in the crafting and DIY community cannot be overstated. It has democratized access to professional-grade printing techniques, enabling individuals to produce custom products that were once the exclusive domain of large manufacturing operations. This shift has not only empowered hobbyists to explore their creativity but has also provided a pathway for entrepreneurs to establish small businesses, catering to the growing demand for personalized and unique items. Whether it's custom phone cases, personalized mugs, or bespoke clothing, printable sublimation vinyl has become an indispensable tool in the pursuit of creative expression and economic opportunity.

Introduction to Printable Sublimation Vinyl

Printable sublimation vinyl is specifically designed to work with sublimation inks, allowing users to print their designs onto the vinyl, which can then be applied to a substrate and heat-pressed to achieve the final product. This vinyl is usually coated with a layer that facilitates the sublimation process, ensuring that the ink fully transfers to the target material without fading or distortion. The quality of the vinyl can significantly impact the outcome of the sublimation process, with higher-quality vinyls offering better ink absorption and transfer rates.

Benefits of Using Printable Sublimation Vinyl

The benefits of incorporating printable sublimation vinyl into one's crafting or business repertoire are numerous. For starters, it offers an unparalleled level of customization, allowing for the creation of intricate designs and patterns that can be applied to a wide variety of materials. This versatility, combined with the relative ease of use, makes printable sublimation vinyl an attractive option for those looking to produce unique items without the need for extensive technical knowledge or expensive equipment.Furthermore, the use of printable sublimation vinyl can significantly reduce production costs, especially for small batches or one-off items. Traditional manufacturing methods often require large minimum order quantities, making them less viable for individuals or small businesses. In contrast, printable sublimation vinyl enables the production of custom items in any quantity, from a single unit to larger batches, without a substantial increase in costs.

Working with Printable Sublimation Vinyl

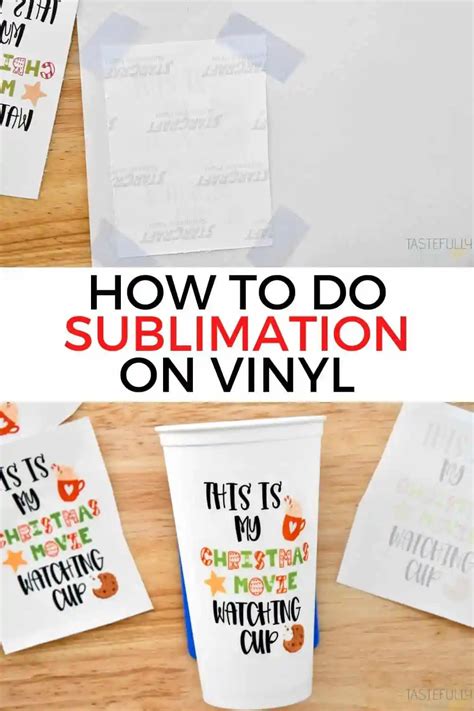

To get started with printable sublimation vinyl, one needs a few basic pieces of equipment, including a sublimation printer, a heat press, and the vinyl itself. The process begins with designing the desired image or pattern using software compatible with the sublimation printer. Once the design is ready, it's printed onto the printable sublimation vinyl using sublimation inks. The next step involves cutting the vinyl to the desired shape or size, which can be done using a craft cutter or scissors, depending on the complexity of the design.

After preparing the vinyl, it's applied to the chosen substrate. This could be a ceramic mug, a piece of fabric, or any other material compatible with the sublimation process. The key to a successful transfer is ensuring that the vinyl is properly aligned and smoothly applied to avoid air bubbles or wrinkles. Finally, the substrate with the applied vinyl is placed in a heat press, where the combination of heat and pressure facilitates the sublimation of the ink into the material, resulting in a durable, full-color image.

Steps for Successful Sublimation with Vinyl

For a successful sublimation process using printable vinyl, follow these steps: - **Design and Print**: Ensure your design is mirrored if necessary and printed with sublimation ink on the printable sublimation vinyl. - **Cut the Vinyl**: Use a craft cutter or scissors to cut out the design, leaving a small margin around the edges if necessary. - **Apply to Substrate**: Smoothly apply the cut vinyl to the substrate, ensuring there are no air bubbles or wrinkles. - **Heat Press**: Place the substrate in a heat press at the appropriate temperature and pressure. The exact settings can vary depending on the substrate and the vinyl used. - **Peel and Inspect**: After the heat press cycle is complete, allow the substrate to cool before peeling off the vinyl. Inspect the result to ensure the image is vibrant and fully transferred.Choosing the Right Printable Sublimation Vinyl

Selecting the appropriate printable sublimation vinyl for a project is crucial for achieving the desired outcome. The market offers a variety of vinyl types, each with its own characteristics, advantages, and best-use scenarios. Some vinyls are designed for specific substrates, such as fabric or rigid materials, and choosing the wrong type can lead to suboptimal results, including poor ink transfer, fading, or the vinyl not adhering properly to the substrate.

When choosing a printable sublimation vinyl, consider the following factors:

- Substrate Compatibility: Ensure the vinyl is compatible with the material you're working with.

- Ink Absorption: Look for vinyls with good ink absorption rates for vibrant colors.

- Adhesion: The vinyl should adhere well to the substrate without leaving residue upon removal.

- Durability: Consider the intended use of the final product and choose a vinyl that offers the necessary durability.

Tips for Working with Different Substrates

Different substrates require slightly different approaches when working with printable sublimation vinyl: - **Fabrics**: Use a vinyl specifically designed for fabrics and ensure the fabric is made from a material that can withstand the sublimation process, such as polyester. - **Ceramics and Glass**: These substrates often require a higher temperature and pressure during the sublimation process. - **Wood and Metal**: Specialized vinyls and coatings may be necessary to achieve a good bond between the sublimation ink and these materials.Common Challenges and Solutions

Like any crafting or printing technique, working with printable sublimation vinyl can present some challenges. Common issues include poor ink transfer, vinyl that doesn't adhere well to the substrate, or designs that fade quickly. To overcome these challenges, it's essential to follow the manufacturer's instructions for both the vinyl and the sublimation ink, ensure the substrate is properly prepared, and adjust the heat press settings as needed.

Additionally, maintaining the sublimation printer and heat press in good working condition, using high-quality materials, and experimenting with different settings and techniques can help in achieving consistent, high-quality results.

Best Practices for Maintenance and Troubleshooting

- **Regularly Clean the Printer**: Prevent clogged heads and ensure consistent ink flow. - **Calibrate the Heat Press**: Regular calibration ensures accurate temperature and pressure readings. - **Test Settings**: Always test sublimation settings on a small, inconspicuous area first.Conclusion and Future Directions

The world of printable sublimation vinyl is continually evolving, with advancements in technology and materials opening up new possibilities for crafters and businesses. As the demand for personalized and unique products continues to grow, the importance of printable sublimation vinyl in meeting this demand cannot be overstated. Whether you're a seasoned crafter looking to expand your repertoire or an entrepreneur seeking to capitalize on the trend towards customization, understanding and mastering the use of printable sublimation vinyl is a valuable skill that can unlock a world of creative and economic possibilities.

Final Thoughts on Printable Sublimation Vinyl

In conclusion, printable sublimation vinyl represents a powerful tool in the realm of crafting and DIY projects, offering a unique blend of versatility, ease of use, and high-quality results. By understanding the basics of sublimation printing, selecting the right materials, and following best practices, individuals can unlock the full potential of printable sublimation vinyl, creating stunning, professional-grade products that meet the growing demand for customization and personalization.Printable Sublimation Vinyl Image Gallery

What is printable sublimation vinyl used for?

+Printable sublimation vinyl is used for creating custom designs and images on various substrates such as fabrics, ceramics, glass, and more through the sublimation printing process.

How do I choose the right printable sublimation vinyl for my project?

+Choosing the right vinyl involves considering the substrate you're working with, the desired durability of the final product, and the specific requirements of your sublimation printer and heat press.

What are some common challenges when working with printable sublimation vinyl?

+Common challenges include poor ink transfer, vinyl that doesn't adhere well to the substrate, and designs that fade quickly. These can often be addressed by adjusting the heat press settings, ensuring proper substrate preparation, and using high-quality materials.

We invite you to share your experiences and tips for working with printable sublimation vinyl in the comments below. Whether you're a seasoned pro or just starting out, your insights can help others navigate the world of sublimation printing and unlock its full creative potential. Don't forget to share this article with anyone who might be interested in exploring the exciting possibilities offered by printable sublimation vinyl. Together, let's dive into the vibrant world of sublimation printing and discover the endless opportunities it has to offer.