Intro

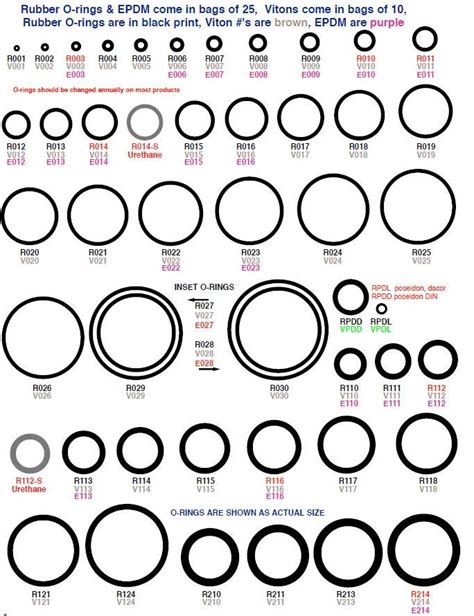

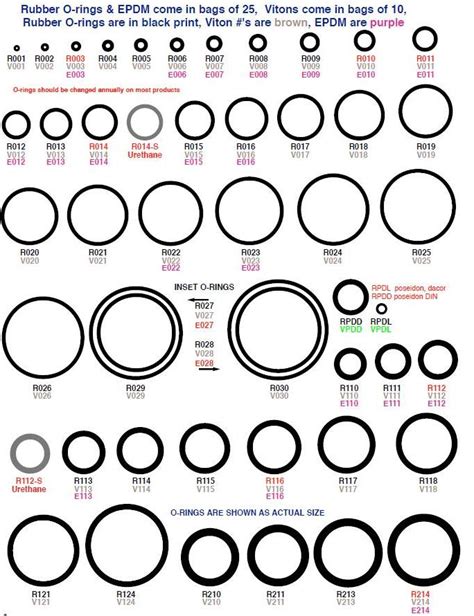

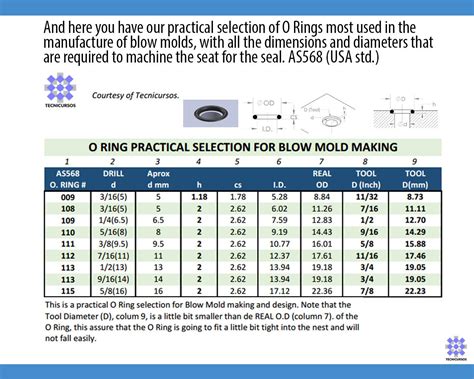

Get the ultimate Printable O Ring Size Chart, featuring precise measurements and dimensions for various O ring seals, gaskets, and rings, including standard and metric sizes, to ensure a perfect fit and seal in your engineering projects.

The importance of having a reliable and accurate O ring size chart cannot be overstated, especially in industries where precision and consistency are crucial. O rings are a fundamental component in many mechanical systems, serving as seals to prevent the leakage of fluids or gases. Their effectiveness is directly tied to their size and material properties, making a printable O ring size chart an indispensable tool for engineers, technicians, and manufacturers. This article aims to delve into the world of O rings, exploring their applications, the significance of sizing, and how a printable size chart can streamline operations and ensure the integrity of mechanical systems.

In various sectors, including automotive, aerospace, and industrial manufacturing, O rings play a pivotal role in maintaining the operational efficiency and safety of equipment. Their versatility and effectiveness in sealing applications have made them a staple in design and engineering. However, the success of an O ring in its intended application hinges on its compatibility with the specific requirements of the system it is meant to seal. This is where the importance of sizing comes into play. An O ring that is too small may not seal effectively, leading to leaks and potential system failures, while one that is too large may not fit properly, causing similar issues.

The challenge of finding the right O ring size can be daunting, given the vast array of sizes and materials available. This complexity necessitates a comprehensive and easily accessible reference tool, such as a printable O ring size chart. Such a chart provides a quick and reliable means of identifying the correct O ring size for a particular application, thereby reducing the risk of incorrect sizing and the consequent failures or inefficiencies. Moreover, having a printable version of this chart allows for its use in a variety of settings, from design offices to factory floors, enhancing collaboration and ensuring consistency across different teams and projects.

Understanding O Ring Sizes

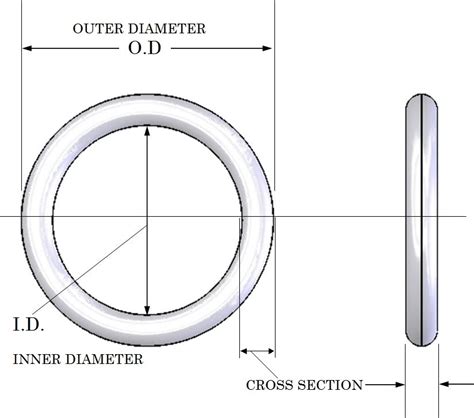

To fully appreciate the utility of a printable O ring size chart, it's essential to understand how O ring sizes are measured and categorized. O rings are typically defined by their inner diameter (ID) and cross-sectional diameter (CS). The ID is the diameter of the hole in the center of the O ring, while the CS refers to the thickness of the O ring. These dimensions are critical because they determine the O ring's sealing capability and its compatibility with the housing or groove it is meant to fit into.

In addition to size, the material of the O ring is also a crucial factor. Different materials offer varying degrees of resistance to temperature, chemicals, and abrasion, making the selection of the right material as important as selecting the right size. Common materials include nitrile (NBR), silicone (VMQ), and fluorocarbon (FKM), each with its unique properties and applications.

Benefits of a Printable O Ring Size Chart

A printable O ring size chart offers several benefits, including convenience, accuracy, and efficiency. By having a physical copy of the chart, professionals can quickly reference O ring sizes without needing to access digital databases or rely on memory. This convenience is particularly valuable in fast-paced environments where time is of the essence.

Moreover, a printable chart can be easily shared among team members or distributed across different departments, ensuring that everyone is on the same page regarding O ring specifications. This uniformity helps in reducing errors and improving the overall quality of work.

Applications of O Rings

The applications of O rings are diverse and widespread, reflecting their versatility and effectiveness as sealing solutions. They are found in engines, gearboxes, cylinders, and valves, among other components, serving to prevent fluid or gas leaks. In the automotive sector, for example, O rings are used in the engine, transmission, and braking systems. Their reliability in high-pressure and high-temperature environments makes them indispensable in these applications.How to Use a Printable O Ring Size Chart

Utilizing a printable O ring size chart is straightforward. The chart typically lists the inner diameter and cross-sectional diameter of various O ring sizes, along with information on their material and any relevant standards or specifications they meet. To find the correct O ring size, one would measure the inner diameter of the groove or housing where the O ring will be placed and then consult the chart to find the corresponding O ring size.

It's also important to consider the material of the O ring based on the application's requirements. For instance, if the O ring will be exposed to high temperatures or certain chemicals, a material with appropriate resistance properties should be chosen.

Steps to Select the Right O Ring

Selecting the right O ring involves several steps: - **Identify the Application**: Determine the environment and conditions under which the O ring will operate. - **Measure the Groove**: Accurately measure the inner diameter and cross-sectional diameter of the groove. - **Consult the Chart**: Use the measurements to find the corresponding O ring size on the chart. - **Choose the Material**: Select a material that is compatible with the application's requirements. - **Verify Standards**: Ensure the O ring meets relevant industry standards for its intended use.Common Challenges and Solutions

One of the common challenges faced when working with O rings is ensuring they are properly seated and functioning as intended. Incorrect sizing or material selection can lead to premature failure, leakage, or other operational issues. To mitigate these risks, it's essential to follow precise measurement and selection protocols, and to consult a reliable printable O ring size chart.

Another challenge is the degradation of O ring materials over time due to exposure to harsh environments. Regular inspection and maintenance can help identify potential issues before they become critical. Additionally, selecting materials with enhanced durability and resistance can prolong the lifespan of the O ring.

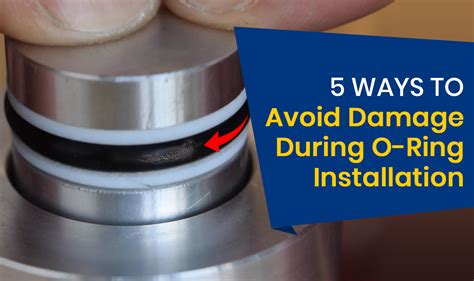

Best Practices for O Ring Installation

Best practices for installing O rings include: - **Cleanliness**: Ensure the groove and surrounding area are free from dirt and debris. - **Lubrication**: Apply a suitable lubricant to reduce friction and facilitate installation. - **Handling**: Handle O rings with care to avoid damaging them. - **Inspection**: Regularly inspect O rings for signs of wear or degradation.Future Developments and Innovations

The field of O ring technology is continually evolving, with advancements in materials science and manufacturing processes leading to the development of more durable, versatile, and efficient O rings. Innovations such as novel materials with enhanced chemical resistance, and advancements in 3D printing technology that allow for the creation of complex O ring geometries, are expected to expand the applications and capabilities of O rings in the future.

Moreover, the integration of digital technologies, such as AI and IoT, into O ring manufacturing and application is likely to improve predictive maintenance, reduce downtime, and enhance overall system performance.

Emerging Trends in O Ring Technology

Emerging trends include: - **Advanced Materials**: Development of new materials with improved properties. - **Digitalization**: Integration of digital technologies into O ring manufacturing and application. - **Sustainability**: Focus on environmentally friendly materials and production processes.Printable O Ring Size Chart Image Gallery

What is the purpose of an O ring size chart?

+An O ring size chart is used to identify the correct size of an O ring for a specific application, ensuring proper fit and function.

How do I measure an O ring size?

+O ring size is measured by its inner diameter (ID) and cross-sectional diameter (CS). Accurate measurement is crucial for selecting the right O ring.

What factors affect O ring performance?

+Factors such as material, size, temperature, and pressure can significantly affect O ring performance and lifespan.

How often should O rings be replaced?

+O rings should be replaced as part of regular maintenance or when signs of wear or damage are observed to prevent system failures.

Can O rings be used in extreme temperatures?

+Yes, certain O ring materials are designed for use in extreme temperatures, but the specific conditions and material limitations must be considered.

In conclusion, a printable O ring size chart is an essential resource for anyone working with O rings, offering a convenient, accurate, and efficient way to select the right O ring for the job. By understanding the importance of O ring sizing, the benefits of a printable chart, and how to use it effectively, professionals can enhance their work quality, reduce errors, and contribute to the reliability and performance of mechanical systems. Whether you're an engineer, technician, or manufacturer, having access to comprehensive and reliable information on O rings can make a significant difference in your projects and operations. We invite you to share your experiences, ask questions, or provide feedback on the use of printable O ring size charts in your field, helping to foster a community of knowledge and innovation.