Intro

Boost forklift safety with 5 essential inspection tips, including pre-operational checks, daily maintenance, and operator training to prevent accidents and ensure warehouse efficiency, optimizing logistics and material handling operations.

Regular forklift inspections are crucial for maintaining a safe and efficient workplace. Forklifts are complex machines that require careful attention to ensure they operate properly and do not pose a risk to operators or surrounding personnel. Neglecting forklift maintenance can lead to accidents, downtime, and increased costs. In this article, we will discuss the importance of forklift inspections and provide valuable tips for conducting thorough checks.

Forklift inspections are a vital part of any warehouse or manufacturing operation. They help identify potential issues before they become major problems, reducing the risk of accidents and minimizing downtime. A well-maintained forklift is not only safer but also more efficient, allowing operators to work more productively and effectively. By prioritizing forklift inspections, businesses can protect their employees, equipment, and bottom line.

Effective forklift inspections require a combination of technical knowledge, attention to detail, and a systematic approach. It's essential to have a clear understanding of the forklift's components, operating procedures, and safety protocols. By following a structured inspection process, operators and maintenance personnel can ensure that all critical systems are functioning correctly and identify potential issues before they become major problems. In the following sections, we will delve into the key aspects of forklift inspections and provide practical tips for conducting thorough checks.

Forklift Inspection Overview

A forklift inspection is a comprehensive check of the vehicle's systems, components, and operating conditions. It's essential to inspect the forklift before each use, as well as on a regular schedule, to ensure that it remains in good working condition. The inspection process typically involves a visual examination, functional tests, and a review of the forklift's maintenance history. By identifying potential issues early, operators and maintenance personnel can take corrective action, preventing accidents and reducing downtime.

Pre-Operational Checks

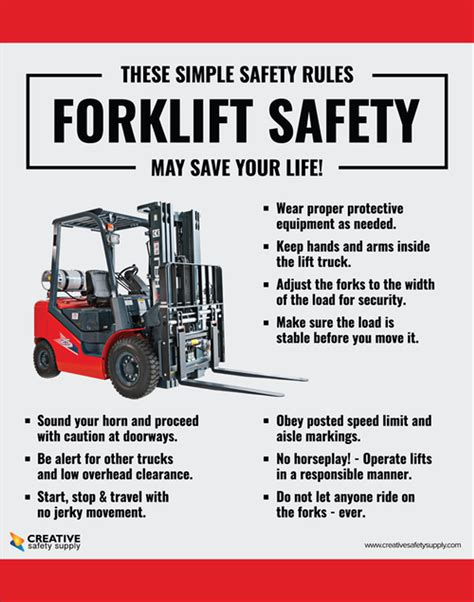

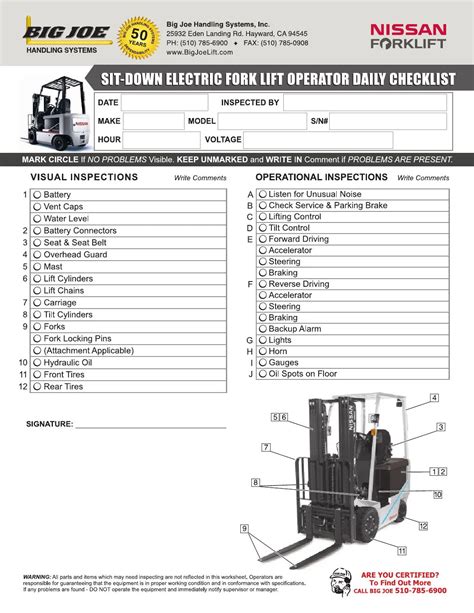

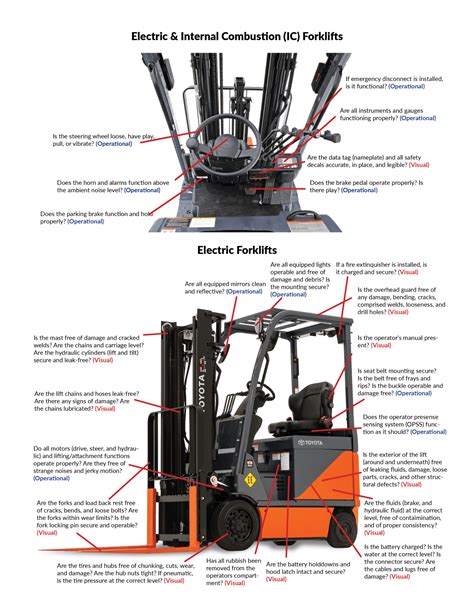

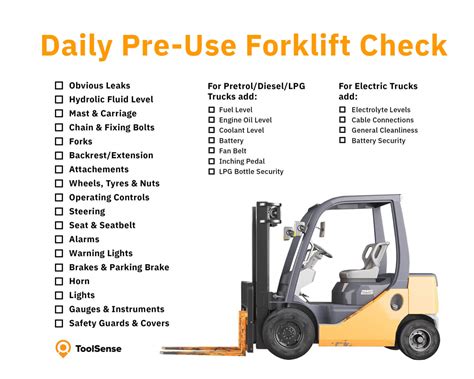

Pre-operational checks are a critical part of the forklift inspection process. These checks involve a visual examination of the forklift's components, including the tires, brakes, hydraulic system, and electrical system. Operators should also test the forklift's controls, including the steering, brakes, and lift mechanisms. By conducting thorough pre-operational checks, operators can ensure that the forklift is safe to operate and identify potential issues before they become major problems.Forklift Safety Features

Forklift safety features are designed to protect operators and surrounding personnel from accidents. These features include warning devices, such as horns and lights, as well as protective structures, like overhead guards and operator compartments. Regular inspections of these safety features are essential to ensure that they are functioning correctly and providing adequate protection. By prioritizing forklift safety, businesses can reduce the risk of accidents and create a safer working environment.

Regular Maintenance

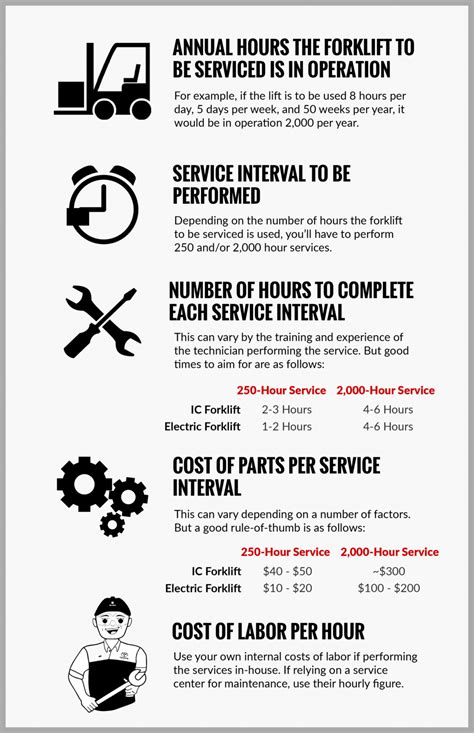

Regular maintenance is critical for extending the life of the forklift and preventing breakdowns. This includes routine tasks, such as oil changes, filter replacements, and tire rotations. Operators and maintenance personnel should also perform more complex tasks, like hydraulic system checks and electrical system tests, on a regular schedule. By staying on top of maintenance, businesses can reduce downtime, minimize repair costs, and optimize forklift performance.Forklift Operator Training

Forklift operator training is essential for ensuring that operators have the knowledge and skills necessary to operate the forklift safely and efficiently. This training should include a combination of classroom instruction and hands-on practice, covering topics like forklift operation, safety procedures, and maintenance protocols. By providing operators with comprehensive training, businesses can reduce the risk of accidents, improve productivity, and create a safer working environment.

Inspection Frequency

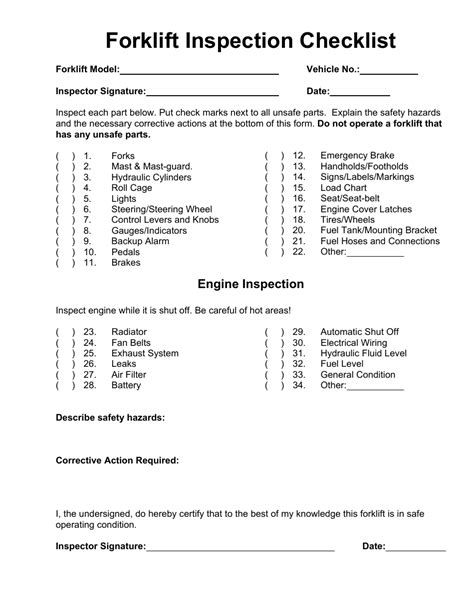

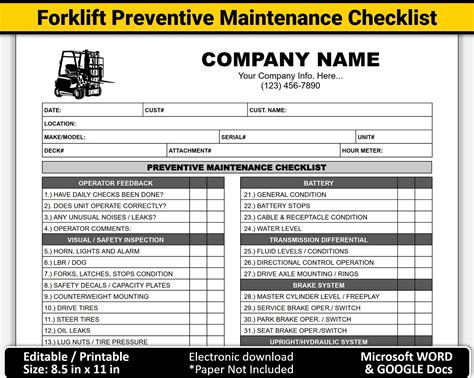

The frequency of forklift inspections depends on various factors, including the forklift's usage, operating conditions, and maintenance history. As a general rule, forklifts should be inspected daily, with more comprehensive checks performed on a weekly, monthly, and annual basis. By following a regular inspection schedule, operators and maintenance personnel can identify potential issues before they become major problems, reducing downtime and minimizing repair costs.Forklift Inspection Checklist

A forklift inspection checklist is a valuable tool for ensuring that all critical systems and components are inspected regularly. This checklist should include items like tire condition, brake function, hydraulic system performance, and electrical system operation. By using a comprehensive checklist, operators and maintenance personnel can streamline the inspection process, reduce the risk of oversights, and ensure that the forklift remains in good working condition.

Documentation and Record-Keeping

Documentation and record-keeping are essential for tracking forklift inspections, maintenance, and repairs. This includes maintaining accurate records of inspection dates, maintenance tasks, and repair work. By keeping detailed records, businesses can demonstrate compliance with regulatory requirements, track forklift performance, and identify areas for improvement.Forklift Maintenance Costs

Forklift maintenance costs can be significant, but regular inspections and maintenance can help minimize these expenses. By identifying potential issues early, businesses can prevent costly repairs, reduce downtime, and optimize forklift performance. Additionally, regular maintenance can help extend the life of the forklift, reducing the need for premature replacements and associated costs.

Best Practices for Forklift Inspections

Best practices for forklift inspections include following a structured inspection process, using a comprehensive checklist, and documenting all findings and maintenance tasks. Operators and maintenance personnel should also prioritize forklift safety, stay up-to-date with regulatory requirements, and continuously monitor forklift performance. By adopting these best practices, businesses can create a safer working environment, reduce downtime, and optimize forklift efficiency.Forklift Inspection Tips

Here are five forklift inspection tips to help you conduct thorough checks:

- Check the tires for wear, damage, and proper inflation

- Test the brakes to ensure they are functioning correctly

- Inspect the hydraulic system for leaks, damage, and proper function

- Check the electrical system for damage, wear, and proper function

- Review the forklift's maintenance history to identify potential issues

Common Forklift Inspection Mistakes

Common forklift inspection mistakes include failing to follow a structured inspection process, neglecting to document findings and maintenance tasks, and ignoring potential issues. Operators and maintenance personnel should also avoid relying solely on visual inspections, as some issues may not be visible to the naked eye. By being aware of these common mistakes, businesses can take steps to prevent them and ensure that their forklifts remain in good working condition.Forklift Inspection Image Gallery

What is the importance of forklift inspections?

+Forklift inspections are crucial for maintaining a safe and efficient workplace. They help identify potential issues before they become major problems, reducing the risk of accidents and minimizing downtime.

How often should forklifts be inspected?

+The frequency of forklift inspections depends on various factors, including the forklift's usage, operating conditions, and maintenance history. As a general rule, forklifts should be inspected daily, with more comprehensive checks performed on a weekly, monthly, and annual basis.

What are the common forklift inspection mistakes?

+Common forklift inspection mistakes include failing to follow a structured inspection process, neglecting to document findings and maintenance tasks, and ignoring potential issues. Operators and maintenance personnel should also avoid relying solely on visual inspections, as some issues may not be visible to the naked eye.

How can forklift inspections be optimized?

+Forklift inspections can be optimized by following a structured inspection process, using a comprehensive checklist, and documenting all findings and maintenance tasks. Operators and maintenance personnel should also prioritize forklift safety, stay up-to-date with regulatory requirements, and continuously monitor forklift performance.

What are the benefits of regular forklift inspections?

+The benefits of regular forklift inspections include reduced downtime, minimized repair costs, and optimized forklift performance. Regular inspections also help identify potential issues before they become major problems, reducing the risk of accidents and creating a safer working environment.

In