Intro

Download 5 free forklift templates for warehouse management, including forklift inspection, operator certification, and maintenance schedules, to enhance safety and efficiency in logistics and material handling operations.

The importance of forklifts in various industries, including manufacturing, logistics, and construction, cannot be overstated. These powerful machines enable the efficient movement of heavy loads, reducing manual labor and increasing productivity. However, the safe and effective operation of forklifts requires careful planning, training, and management. One crucial aspect of forklift management is the use of templates to standardize and streamline operations. In this article, we will explore five free forklift templates that can help businesses improve their forklift-related processes.

Forklifts are complex machines that demand regular maintenance, operator training, and strict safety protocols. Neglecting these aspects can lead to accidents, damage to equipment, and decreased productivity. By utilizing forklift templates, companies can ensure that their forklift operations are well-organized, compliant with regulations, and focused on safety. These templates can be used for a variety of purposes, including operator training, maintenance scheduling, and accident reporting.

The use of forklift templates is not limited to large corporations; small and medium-sized enterprises can also benefit from implementing these tools. By standardizing forklift operations, businesses can reduce errors, improve communication among team members, and enhance overall efficiency. Moreover, forklift templates can be easily customized to meet the specific needs of each organization, making them a versatile and valuable resource for any company that relies on forklifts.

Introduction to Forklift Templates

Forklift templates are pre-designed documents that provide a structured format for managing various aspects of forklift operations. These templates can be used for creating operator training manuals, maintenance schedules, safety inspection checklists, and accident report forms. By using forklift templates, companies can ensure that their forklift operations are consistent, safe, and compliant with industry regulations.

Benefits of Using Forklift Templates

The benefits of using forklift templates are numerous. Some of the most significant advantages include: * Improved safety: Forklift templates help ensure that all safety protocols are followed, reducing the risk of accidents and injuries. * Increased efficiency: By standardizing forklift operations, companies can streamline their processes, reducing downtime and improving productivity. * Enhanced compliance: Forklift templates can help businesses comply with industry regulations and standards, reducing the risk of fines and penalties. * Better communication: Forklift templates provide a clear and consistent format for communication among team members, reducing errors and misunderstandings.5 Free Forklift Templates

Here are five free forklift templates that can help businesses improve their forklift-related processes:

- Forklift Operator Training Template: This template provides a structured format for creating operator training manuals, including sections for safety procedures, operating instructions, and maintenance requirements.

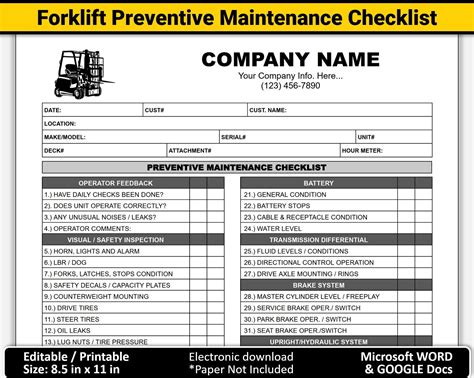

- Forklift Maintenance Schedule Template: This template helps companies schedule regular maintenance tasks, including daily, weekly, and monthly checks, to ensure that their forklifts are in good working condition.

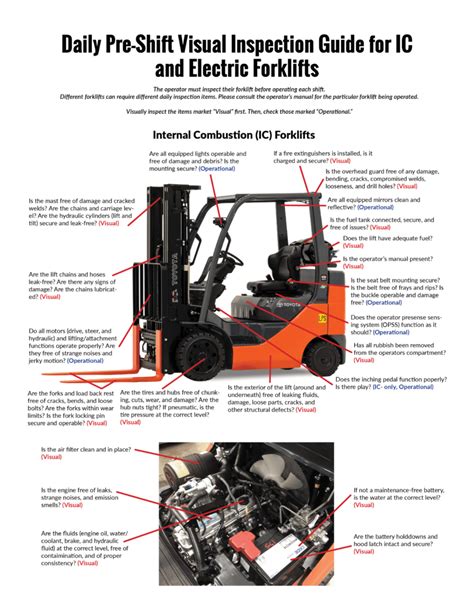

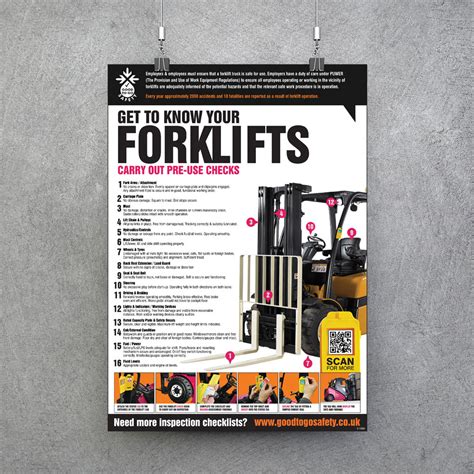

- Forklift Safety Inspection Checklist Template: This template provides a comprehensive checklist for safety inspections, including items such as tire condition, brake function, and hydraulic system performance.

- Forklift Accident Report Form Template: This template helps companies document and investigate accidents involving forklifts, including sections for incident description, witness statements, and corrective actions.

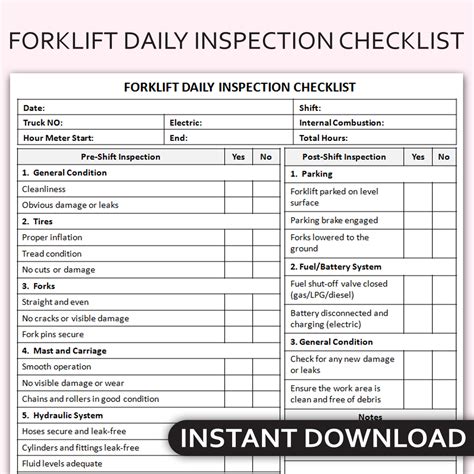

- Forklift Daily Inspection Template: This template provides a daily inspection checklist for forklift operators, including items such as fluid levels, tire pressure, and safety equipment.

How to Use Forklift Templates

Using forklift templates is straightforward. Here are the steps to follow: * Download the template: Choose the template that best suits your needs and download it to your computer. * Customize the template: Modify the template to meet your company's specific requirements, including adding your logo, company name, and relevant policies. * Fill out the template: Complete the template with the required information, such as operator names, forklift serial numbers, and maintenance schedules. * Review and update: Regularly review and update the template to ensure that it remains relevant and effective.Best Practices for Forklift Operation

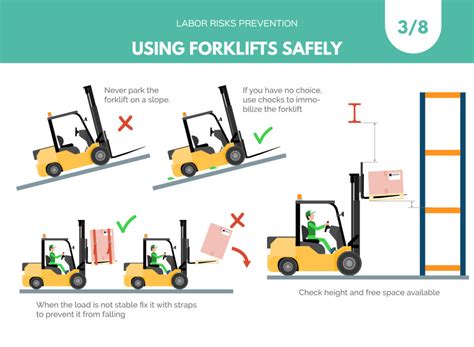

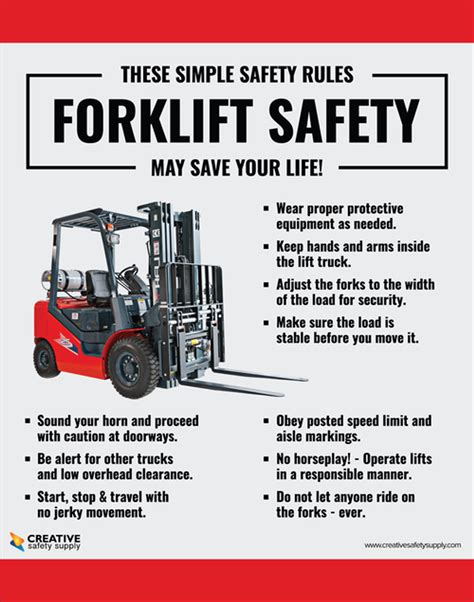

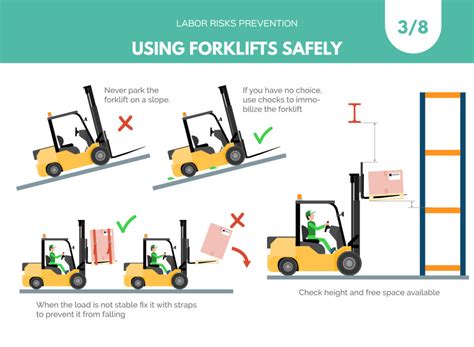

In addition to using forklift templates, companies should follow best practices for forklift operation. Some of the most important best practices include:

- Providing regular operator training: Ensure that all forklift operators receive comprehensive training on safety procedures, operating instructions, and maintenance requirements.

- Conducting regular safety inspections: Perform daily, weekly, and monthly safety inspections to identify and address potential hazards.

- Maintaining forklifts regularly: Schedule regular maintenance tasks, including daily, weekly, and monthly checks, to ensure that forklifts are in good working condition.

- Encouraging safe operating practices: Promote safe operating practices, such as wearing personal protective equipment, following traffic rules, and avoiding distractions.

Forklift Safety Tips

Here are some additional forklift safety tips: * Always wear personal protective equipment, including a hard hat, safety glasses, and steel-toed shoes. * Follow traffic rules, including yielding to pedestrians and other vehicles. * Avoid distractions, such as using a cell phone or eating while operating a forklift. * Keep a safe distance from other vehicles and pedestrians. * Use warning devices, such as horns and lights, to alert others of your presence.Forklift Maintenance and Repair

Regular maintenance and repair are essential for ensuring that forklifts operate safely and efficiently. Here are some tips for maintaining and repairing forklifts:

- Schedule regular maintenance tasks: Perform daily, weekly, and monthly checks to identify and address potential issues.

- Keep a maintenance log: Record all maintenance activities, including dates, times, and tasks performed.

- Use genuine parts: Replace worn or damaged parts with genuine components to ensure optimal performance and safety.

- Train maintenance personnel: Ensure that maintenance personnel receive comprehensive training on forklift maintenance and repair procedures.

Forklift Operator Training Programs

Forklift operator training programs are essential for ensuring that operators have the knowledge and skills necessary to operate forklifts safely and efficiently. Here are some tips for creating an effective forklift operator training program: * Develop a comprehensive training manual: Create a manual that covers all aspects of forklift operation, including safety procedures, operating instructions, and maintenance requirements. * Provide hands-on training: Offer hands-on training to give operators practical experience operating forklifts. * Use visual aids: Use visual aids, such as videos and diagrams, to help operators understand complex concepts. * Evaluate operator performance: Regularly evaluate operator performance to identify areas for improvement.Forklift Image Gallery

What is the importance of forklift templates in ensuring safe operation?

+Forklift templates play a crucial role in ensuring safe operation by providing a structured format for managing various aspects of forklift operations, including operator training, maintenance scheduling, and safety inspections.

How can I customize forklift templates to meet my company's specific needs?

+You can customize forklift templates by modifying the template to include your company's logo, policies, and procedures. You can also add or remove sections as needed to ensure that the template meets your company's specific requirements.

What are some best practices for forklift operation that I should follow?

+Some best practices for forklift operation include providing regular operator training, conducting regular safety inspections, maintaining forklifts regularly, and encouraging safe operating practices.

How often should I perform safety inspections on my forklifts?

+You should perform safety inspections on your forklifts daily, weekly, and monthly to identify and address potential hazards. You should also keep a record of all safety inspections to ensure that you can track any issues that may arise.

What are some common hazards associated with forklift operation?

+Some common hazards associated with forklift operation include accidents, injuries, and damage to equipment. You can minimize these hazards by following best practices for forklift operation, providing regular operator training, and conducting regular safety inspections.

In

Final Thoughts