Intro

Safeguard your workplace with our Eyewash Station Inspection Checklist Printable, ensuring compliance and proper maintenance of emergency eyewash equipment, eye wash stations, and safety showers.

The importance of a well-maintained eyewash station cannot be overstated, particularly in workplaces where employees are exposed to hazardous substances. Regular inspections are crucial to ensure that these stations are functioning properly and can provide effective emergency eye care when needed. An eyewash station inspection checklist is a valuable tool for facilities managers, safety officers, and employees to guarantee compliance with regulatory standards and to prevent injuries. This article will delve into the significance of eyewash stations, the components of a comprehensive inspection checklist, and the steps to follow for a thorough inspection.

In many industries, such as manufacturing, construction, and laboratories, workers are at risk of chemical splashes or other eye hazards. The Occupational Safety and Health Administration (OSHA) requires that eyewash stations be installed and maintained in areas where workers are exposed to injurious corrosive materials. However, simply having an eyewash station is not enough; it must be regularly inspected to ensure it is in good working condition. This is where an eyewash station inspection checklist comes into play, providing a systematic approach to evaluating the readiness and functionality of these critical safety devices.

The use of an eyewash station inspection checklist printable can streamline the process, making it easier for individuals to conduct inspections without overlooking critical components. These checklists typically cover aspects such as the location of the eyewash station, its accessibility, the condition of the equipment, and whether it meets the required flow rate and temperature standards. By utilizing such a checklist, workplaces can enhance their safety protocols, reduce the risk of eye injuries, and demonstrate their commitment to providing a safe working environment.

Introduction to Eyewash Stations

Eyewash stations are emergency devices designed to flush out chemicals, dust, or other foreign materials from the eyes. They are a critical component of workplace safety in environments where hazardous substances are present. The primary purpose of an eyewash station is to provide a quick and effective means of rinsing the eyes to prevent or minimize injury. There are different types of eyewash stations, including wall-mounted, pedestal-mounted, and portable units, each designed to suit various workplace settings and needs.

Importance of Regular Inspections

Regular inspections of eyewash stations are vital for several reasons. Firstly, they help ensure that the equipment is in good working condition and can be relied upon in emergency situations. Secondly, inspections can identify any maintenance needs, such as cleaning or replacing parts, which can prevent equipment failure. Lastly, regular inspections demonstrate a proactive approach to safety, which can boost employee confidence and contribute to a positive safety culture within the organization.

Components of an Eyewash Station Inspection Checklist

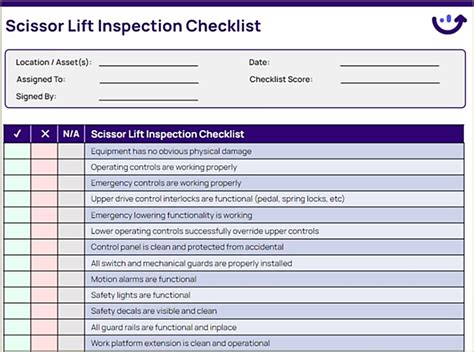

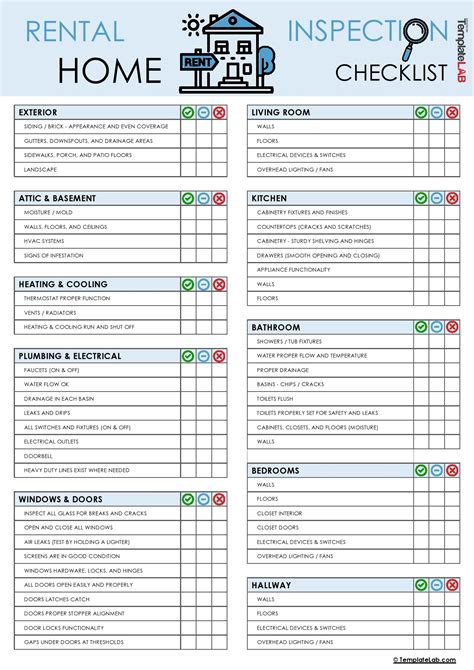

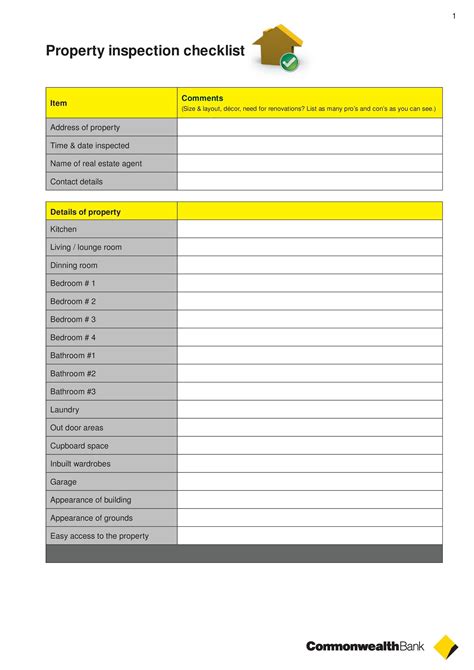

A comprehensive eyewash station inspection checklist should cover several key areas:

- Location and Accessibility: The station should be easily accessible, located in an area that is immediately accessible to employees who work with hazardous substances, and should not be obstructed by any obstacles.

- Equipment Condition: The inspection should verify that all parts of the eyewash station are in good condition, with no signs of damage, rust, or corrosion.

- Flow Rate: The eyewash station should provide a flow rate of 0.4 gallons per minute (gpm) for a minimum of 15 minutes, as per ANSI standards.

- Temperature: The water temperature should be between 60°F and 100°F (15.5°C and 37.7°C) to avoid causing further injury.

- Testing and Maintenance Records: Records of regular testing and maintenance should be up to date, indicating that the station has been properly inspected and maintained.

Steps for Conducting an Inspection

Conducting an eyewash station inspection involves several steps:

- Visual Inspection: Begin by visually examining the eyewash station for any signs of damage or wear.

- Activate the Station: Turn on the eyewash station to check the flow rate and ensure that it operates smoothly.

- Check the Water Temperature: Verify that the water temperature is within the acceptable range.

- Inspect the Drainage: Ensure that the drainage system functions properly to prevent water from accumulating.

- Review Maintenance Records: Check the maintenance and testing records to ensure compliance with regulatory standards.

Benefits of Using an Inspection Checklist

Utilizing an eyewash station inspection checklist offers several benefits:

- Ensures Compliance: It helps organizations comply with OSHA and ANSI standards.

- Enhances Safety: Regular inspections can identify and rectify potential issues before they lead to accidents.

- Streamlines Maintenance: It provides a systematic approach to maintenance, ensuring that all aspects of the eyewash station are regularly checked and maintained.

- Promotes a Safety Culture: Demonstrates a commitment to employee safety and well-being.

Gallery of Eyewash Stations

Eyewash Station Image Gallery

Frequently Asked Questions

What is the purpose of an eyewash station inspection checklist?

+The purpose of an eyewash station inspection checklist is to ensure that eyewash stations are properly maintained and functioning correctly to provide emergency eye care in workplaces where hazardous substances are present.

How often should eyewash stations be inspected?

+Eyewash stations should be inspected weekly to ensure they are in good working condition and meet the required standards.

What are the key components of an eyewash station inspection checklist?

+The key components include location and accessibility, equipment condition, flow rate, temperature, and review of maintenance records.

Why is it important to maintain eyewash stations?

+Maintaining eyewash stations is crucial for preventing eye injuries and ensuring compliance with safety regulations and standards.

Can an eyewash station inspection checklist be customized?

+Yes, an eyewash station inspection checklist can be customized to fit the specific needs and requirements of a workplace.

In conclusion, an eyewash station inspection checklist is a vital tool for ensuring the safety and well-being of employees in workplaces where hazardous substances are present. By understanding the importance of eyewash stations, the components of a comprehensive inspection checklist, and the steps for conducting an inspection, organizations can proactively manage safety risks and comply with regulatory standards. We invite readers to share their experiences with eyewash station inspections and to explore how implementing a rigorous inspection checklist can enhance their workplace safety culture. Feel free to comment below or share this article with others who might benefit from this information.