Intro

Download a free preventive maintenance template in Excel to streamline schedules, track equipment, and reduce downtime with predictive maintenance, routine inspections, and inventory management.

Preventive maintenance is a crucial aspect of ensuring the longevity and efficiency of equipment, machinery, and other assets. It involves regular checks and maintenance tasks to prevent breakdowns, reduce downtime, and optimize performance. In today's fast-paced industrial and commercial environments, having a well-structured preventive maintenance schedule is essential for minimizing costs, enhancing safety, and maintaining productivity.

The importance of preventive maintenance cannot be overstated. It not only helps in identifying potential issues before they become major problems but also ensures that equipment operates at its optimal level. This, in turn, can lead to significant cost savings by reducing the need for repairs, minimizing downtime, and extending the lifespan of assets. Furthermore, preventive maintenance plays a critical role in enhancing workplace safety by identifying and mitigating potential hazards associated with faulty or malfunctioning equipment.

In managing preventive maintenance, having the right tools and resources is vital. One of the most effective tools for organizing and scheduling maintenance tasks is a preventive maintenance template in Excel. Excel templates offer a structured format for planning, tracking, and analyzing maintenance activities. They can be customized to fit the specific needs of an organization, allowing for the inclusion of detailed schedules, task lists, and performance metrics. By utilizing a preventive maintenance template, businesses can streamline their maintenance operations, improve compliance with regulatory requirements, and make data-driven decisions to optimize their maintenance strategies.

Benefits of Preventive Maintenance

The benefits of preventive maintenance are multifaceted and can have a significant impact on the overall efficiency and profitability of an organization. Some of the key advantages include:

- Reduced Downtime: By identifying and addressing potential issues before they cause equipment failure, businesses can minimize downtime and ensure continuous operation.

- Cost Savings: Preventive maintenance can lead to substantial cost savings by reducing the need for costly repairs, minimizing the replacement of parts, and lowering energy consumption.

- Improved Safety: Regular maintenance helps in identifying and mitigating safety hazards, thereby reducing the risk of accidents and ensuring a safer working environment.

- Extended Equipment Lifespan: Proper maintenance can significantly extend the lifespan of equipment and assets, delaying the need for replacements and reducing capital expenditures.

- Enhanced Product Quality: Well-maintained equipment is more likely to produce high-quality products, reducing waste and the need for rework.

Creating a Preventive Maintenance Schedule

Creating an effective preventive maintenance schedule involves several steps, including:

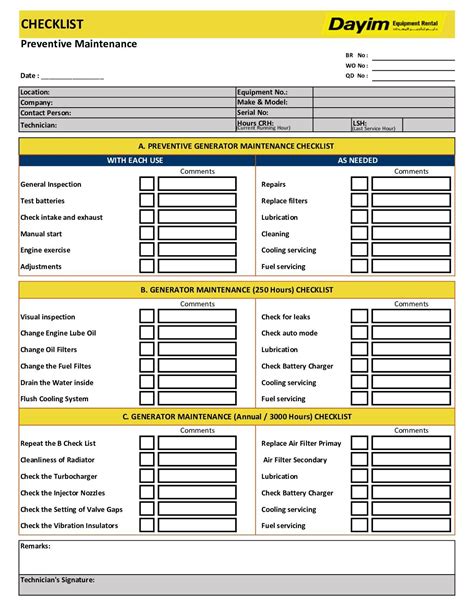

- Asset Identification: Identify all equipment and assets that require maintenance.

- Task Definition: Determine the specific maintenance tasks needed for each asset.

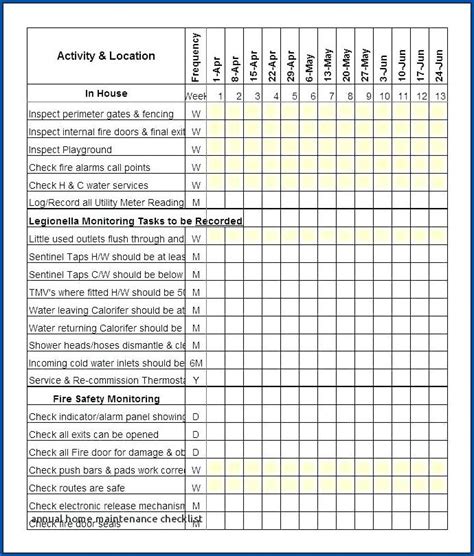

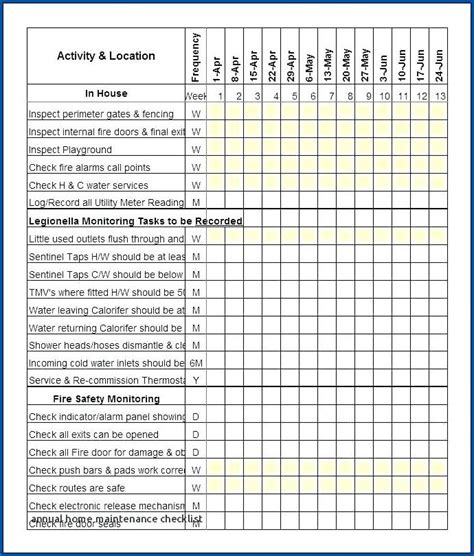

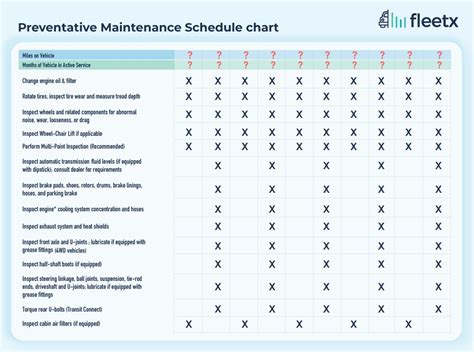

- Frequency Determination: Decide on the frequency of each maintenance task based on manufacturer recommendations, usage, and historical data.

- Resource Allocation: Allocate necessary resources, including personnel, parts, and tools.

- Schedule Creation: Create a schedule that outlines all maintenance tasks, frequencies, and responsible personnel.

- Monitoring and Adjustment: Continuously monitor the effectiveness of the schedule and make adjustments as necessary.

Using a Preventive Maintenance Template in Excel

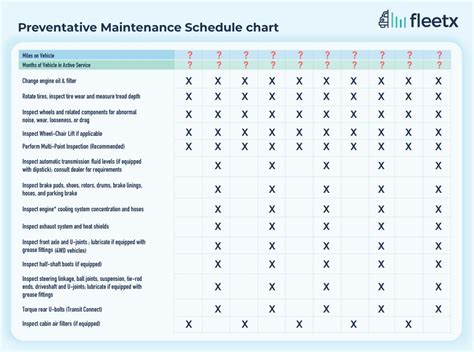

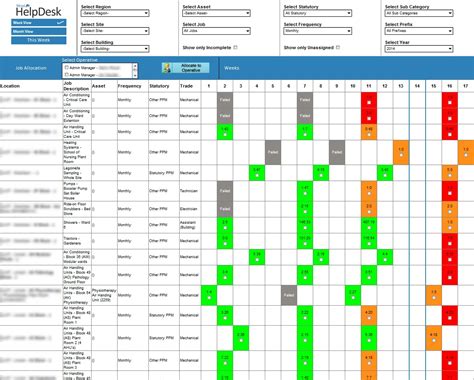

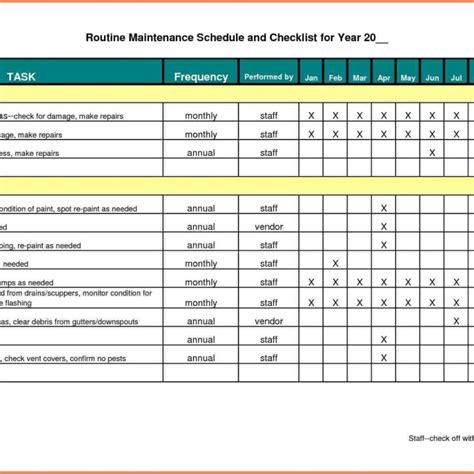

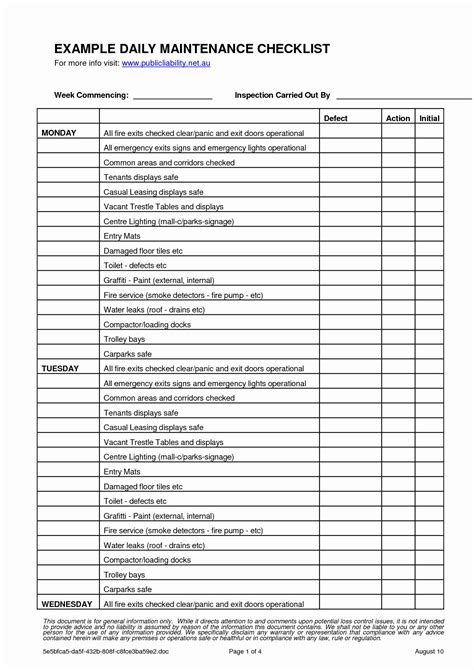

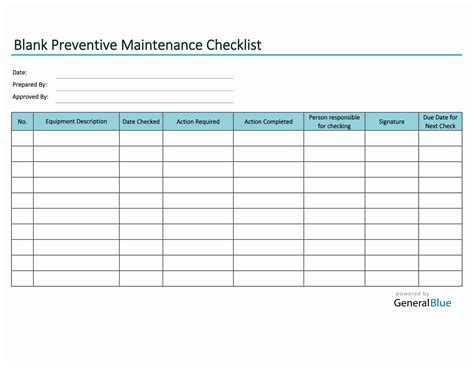

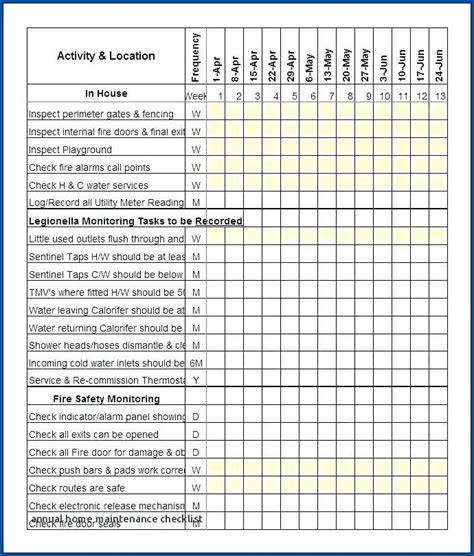

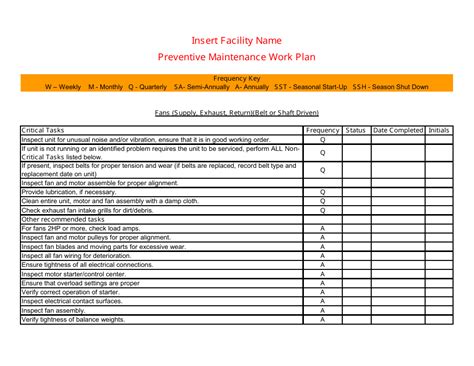

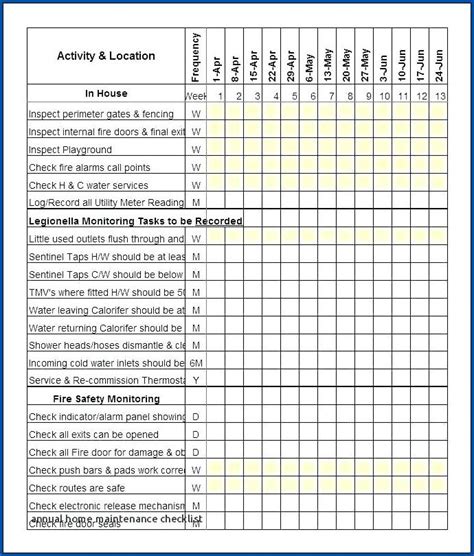

A preventive maintenance template in Excel can be a powerful tool for managing maintenance activities. These templates typically include:

- Asset Lists: Spreadsheets for listing all equipment and assets.

- Maintenance Schedules: Calendars or tables for scheduling maintenance tasks.

- Task Lists: Detailed lists of maintenance tasks to be performed.

- Performance Metrics: Sections for tracking and analyzing maintenance performance.

To use a preventive maintenance template effectively:

- Customize the Template: Adapt the template to fit your organization's specific needs.

- Enter Asset Information: Populate the template with your equipment and asset data.

- Schedule Maintenance: Use the template to schedule maintenance tasks based on your defined frequencies.

- Track Progress: Regularly update the template to reflect completed tasks and any issues encountered.

- Analyze Performance: Utilize the template's analytical capabilities to assess the effectiveness of your maintenance program and identify areas for improvement.

Free Preventive Maintenance Template Excel Download

For businesses and individuals looking to implement a preventive maintenance program, downloading a free preventive maintenance template in Excel can be a great starting point. These templates are readily available online and can be customized to suit specific maintenance needs. When selecting a template, consider the following factors:

- Complexity: Choose a template that matches your level of familiarity with Excel and your maintenance management needs.

- Customizability: Opt for a template that can be easily adapted to your organization's structure and requirements.

- Features: Select a template that includes the features you need, such as scheduling, task management, and performance tracking.

Implementing Preventive Maintenance

Implementing a preventive maintenance program requires a structured approach:

- Training Personnel: Ensure that maintenance staff are trained on the new procedures and the use of the Excel template.

- Initial Assessment: Conduct an initial assessment of all assets to identify any immediate maintenance needs.

- Schedule Activation: Activate the maintenance schedule, ensuring that all tasks are assigned and tracked.

- Continuous Monitoring: Regularly review the effectiveness of the maintenance program and make adjustments as necessary.

- Feedback Loop: Establish a feedback mechanism to capture insights from maintenance personnel and other stakeholders, using this information to refine the program.

Gallery of Preventive Maintenance Templates

Preventive Maintenance Templates Gallery

Frequently Asked Questions

What is preventive maintenance?

+Preventive maintenance refers to the regular maintenance tasks performed on equipment and assets to prevent breakdowns, reduce downtime, and optimize performance.

Why is preventive maintenance important?

+Preventive maintenance is important because it helps in reducing costs, enhancing safety, minimizing downtime, and extending the lifespan of equipment and assets.

How can I create a preventive maintenance schedule?

+To create a preventive maintenance schedule, identify your assets, define necessary tasks, determine task frequencies, allocate resources, and use a template or software to schedule and track maintenance.

What are the benefits of using a preventive maintenance template in Excel?

+The benefits include streamlined maintenance operations, improved compliance, enhanced tracking and analysis capabilities, and the ability to make data-driven decisions to optimize maintenance strategies.

Where can I find a free preventive maintenance template in Excel?

+Free preventive maintenance templates in Excel can be found online through a variety of sources, including maintenance management websites, Excel template repositories, and industry-specific forums.

In conclusion, preventive maintenance is a vital component of any successful maintenance strategy, offering numerous benefits that can significantly impact an organization's efficiency, safety, and bottom line. By understanding the importance of preventive maintenance, creating an effective schedule, and utilizing tools like Excel templates, businesses can ensure their equipment and assets operate at optimal levels, minimizing downtime and maximizing productivity. Whether you're looking to implement a preventive maintenance program for the first time or seeking to enhance your existing strategies, the insights and resources provided here can serve as a valuable guide on your journey to maintenance excellence. We invite you to share your experiences, ask questions, and explore the world of preventive maintenance further, as together, we can achieve greater reliability, efficiency, and success in our maintenance endeavors.