Intro

Boost equipment lifespan with 5 preventive maintenance tips, including routine inspections, scheduled repairs, and proactive replacements, to minimize downtime and optimize performance, ensuring reliability and efficiency in machinery operations and maintenance strategies.

Preventive maintenance is a crucial aspect of ensuring the longevity and efficiency of equipment, machinery, and even vehicles. By incorporating regular maintenance checks and tasks into your routine, you can significantly reduce the risk of unexpected breakdowns, minimize downtime, and save on costly repairs. In today's fast-paced world, it's easy to overlook the importance of preventive maintenance, but the benefits it offers are undeniable. Whether you're a business owner looking to optimize your operations or an individual seeking to prolong the life of your personal assets, preventive maintenance is an investment worth considering. As we delve into the world of preventive maintenance, it's essential to understand the various ways it can be applied to different aspects of our lives, from industrial settings to personal belongings.

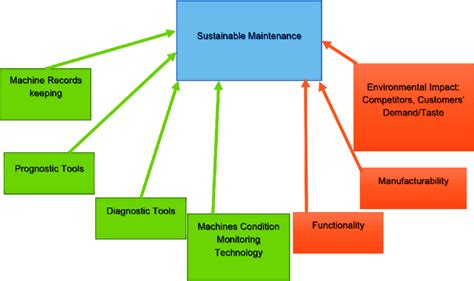

Regular maintenance checks can help identify potential issues before they become major problems, allowing for prompt action to be taken. This proactive approach not only saves time and money but also enhances safety and reduces the risk of accidents. In industries where equipment and machinery are integral to daily operations, preventive maintenance is particularly vital. By staying on top of maintenance schedules, businesses can ensure continuous production, meet deadlines, and maintain a competitive edge. Moreover, preventive maintenance can also contribute to environmental sustainability by reducing waste, conserving energy, and promoting the use of eco-friendly practices. As the importance of preventive maintenance becomes increasingly apparent, it's time to explore some practical tips for implementing it in your daily life.

Introduction to Preventive Maintenance

Benefits of Preventive Maintenance

Preventive Maintenance Tips

Implementing Preventive Maintenance

Common Preventive Maintenance Mistakes

Best Practices for Preventive Maintenance

Preventive Maintenance and Safety

Preventive Maintenance and Environmental Sustainability

Gallery of Preventive Maintenance Images

Preventive Maintenance Image Gallery

What is preventive maintenance?

+Preventive maintenance refers to the regular maintenance activities performed to prevent equipment and machinery from failing or malfunctioning.

Why is preventive maintenance important?

+Preventive maintenance is important because it helps reduce downtime, increases efficiency, and saves costs. It also enhances safety and environmental sustainability.

How can I implement preventive maintenance?

+To implement preventive maintenance, you need to develop a maintenance schedule, train personnel, and use high-quality materials and replacement parts. You should also continuously monitor performance and adjust the maintenance schedule as needed.

What are the benefits of preventive maintenance?

+The benefits of preventive maintenance include reduced downtime, increased efficiency, lower maintenance and repair costs, improved safety, and enhanced environmental sustainability.

How can I ensure the effectiveness of preventive maintenance?

+To ensure the effectiveness of preventive maintenance, you need to follow best practices, such as developing a comprehensive maintenance schedule, using high-quality materials and replacement parts, and continuously monitoring performance.

As we conclude our exploration of preventive maintenance, it's essential to recognize the significance of this practice in ensuring the longevity and efficiency of equipment, machinery, and vehicles. By incorporating regular maintenance checks and tasks into your routine, you can enjoy numerous benefits, from reduced downtime and increased productivity to improved safety and environmental sustainability. Whether you're a business owner or an individual, preventive maintenance is an investment worth considering. We invite you to share your thoughts and experiences with preventive maintenance in the comments section below. Feel free to ask questions or provide feedback, and don't forget to share this article with others who may benefit from the information. Together, we can promote a culture of preventive maintenance and enjoy the many benefits it has to offer.