Intro

Boost efficiency with 5 Lean Templates, streamlining processes via agile methodologies, lean management, and continuous improvement techniques.

The concept of lean templates has gained significant attention in recent years, particularly in the realm of product development, manufacturing, and business operations. At its core, lean thinking is about maximizing value for customers while minimizing waste and optimizing processes. In this context, lean templates serve as essential tools for organizations seeking to streamline their workflows, enhance productivity, and improve overall efficiency.

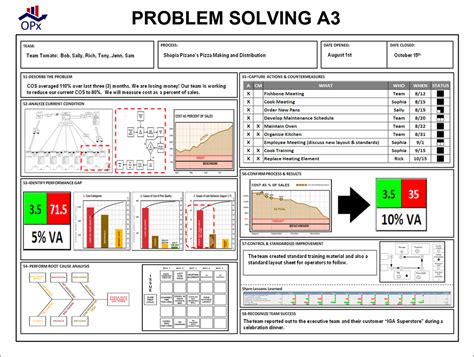

The importance of lean templates cannot be overstated. They provide a structured approach to problem-solving, allowing teams to identify areas of inefficiency, analyze root causes, and implement targeted improvements. By leveraging lean templates, organizations can reduce waste, lower costs, and enhance customer satisfaction. Moreover, these templates facilitate a culture of continuous improvement, encouraging employees to think critically and creatively about process optimization.

In today's fast-paced business environment, the ability to adapt and innovate quickly is crucial for success. Lean templates offer a valuable framework for achieving this goal. By standardizing processes and eliminating non-value-added activities, organizations can respond more effectively to changing market conditions, customer needs, and competitive pressures. Furthermore, lean templates help to foster a collaborative work environment, where cross-functional teams can work together to drive improvement initiatives and share best practices.

Introduction to Lean Templates

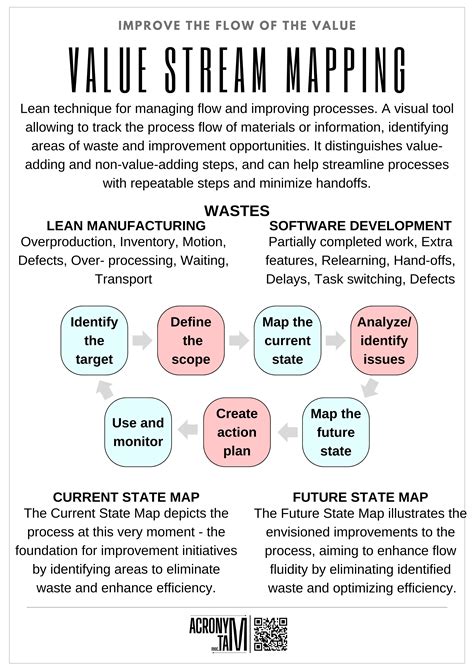

Lean templates are pre-designed documents or spreadsheets that guide users through a specific process or methodology. They are typically used to support lean principles, such as value stream mapping, root cause analysis, and continuous improvement. By utilizing lean templates, organizations can save time, reduce errors, and improve the overall quality of their processes.

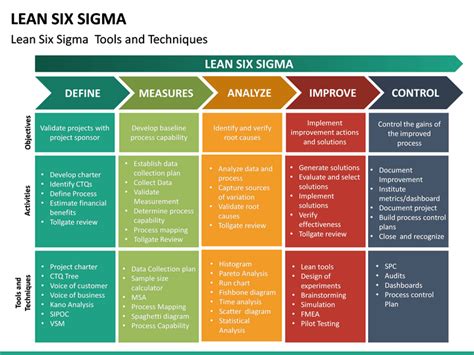

Types of Lean Templates

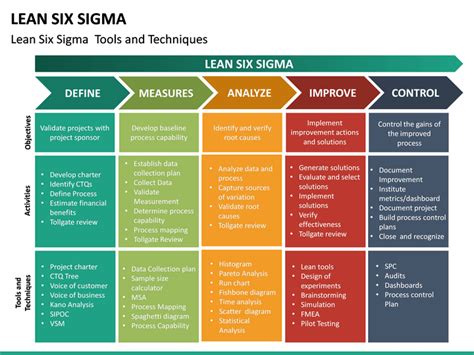

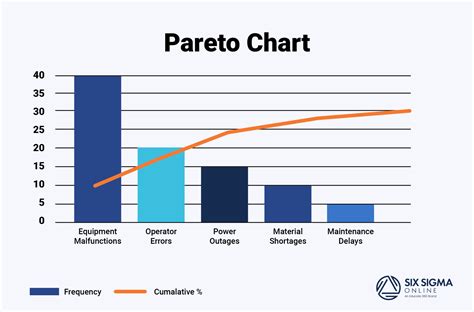

There are various types of lean templates available, each serving a distinct purpose. Some common examples include: * Value stream mapping templates: Used to visualize and analyze the flow of materials and information across a value stream. * Root cause analysis templates: Employed to identify and address the underlying causes of problems or defects. * Kaizen templates: Designed to facilitate continuous improvement initiatives and track progress over time. * Pareto analysis templates: Used to identify and prioritize problems based on their frequency and impact. * Fishbone diagram templates: Applied to visualize and organize the possible causes of a problem.Benefits of Lean Templates

The benefits of lean templates are numerous and well-documented. Some of the most significant advantages include:

- Improved efficiency: Lean templates help to streamline processes, reduce waste, and optimize resource allocation.

- Enhanced productivity: By standardizing processes and eliminating non-value-added activities, organizations can increase productivity and output.

- Better decision-making: Lean templates provide a structured approach to problem-solving, enabling teams to make informed, data-driven decisions.

- Increased customer satisfaction: By focusing on value-added activities and eliminating waste, organizations can improve the quality and timeliness of their products or services.

- Cost savings: Lean templates help to reduce waste, lower costs, and improve overall profitability.

Implementing Lean Templates

Implementing lean templates requires a structured approach. The following steps can help organizations to get started: 1. Identify areas for improvement: Use value stream mapping or other lean methodologies to identify areas where processes can be improved. 2. Select the right template: Choose a lean template that aligns with the specific needs and goals of the organization. 3. Customize the template: Tailor the template to fit the unique requirements of the organization and the specific process being improved. 4. Train employees: Provide training and support to ensure that employees understand how to use the lean template effectively. 5. Monitor and evaluate: Continuously monitor and evaluate the effectiveness of the lean template, making adjustments as needed.Common Lean Templates

Some common lean templates include:

- Value stream mapping templates: Used to visualize and analyze the flow of materials and information across a value stream.

- Spaghetti diagrams: Employed to visualize and improve the flow of materials and information across a process.

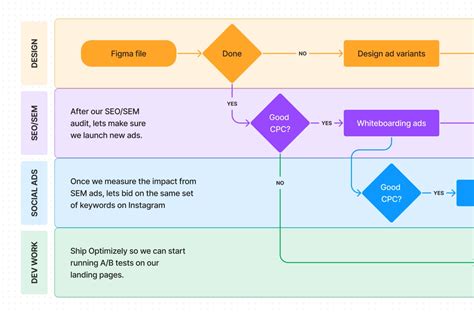

- Swimlane diagrams: Used to visualize and improve the flow of work across multiple departments or functions.

- Kaizen templates: Designed to facilitate continuous improvement initiatives and track progress over time.

- Pareto analysis templates: Used to identify and prioritize problems based on their frequency and impact.

Best Practices for Using Lean Templates

To get the most out of lean templates, organizations should follow best practices such as: * Customize templates to fit specific needs and goals. * Provide training and support to ensure effective use. * Continuously monitor and evaluate the effectiveness of templates. * Encourage employee engagement and participation in the improvement process. * Focus on value-added activities and eliminate waste.Lean Template Examples

Some examples of lean templates in action include:

- A manufacturing company using a value stream mapping template to identify and eliminate waste in its production process.

- A healthcare organization using a root cause analysis template to identify and address the underlying causes of patient safety issues.

- A software development company using a Kaizen template to facilitate continuous improvement initiatives and track progress over time.

- A retail company using a Pareto analysis template to identify and prioritize inventory management issues.

Challenges and Limitations

While lean templates can be highly effective, there are also challenges and limitations to consider. Some of the most common challenges include: * Resistance to change: Employees may resist the introduction of new templates and processes. * Lack of training: Employees may not have the necessary skills or knowledge to use lean templates effectively. * Inadequate resources: Organizations may not have the necessary resources or budget to implement and maintain lean templates. * Inability to scale: Lean templates may not be scalable to larger or more complex organizations.Future of Lean Templates

The future of lean templates is likely to involve increased digitization and automation. Some potential trends and developments include:

- Cloud-based lean templates: Allowing for greater accessibility and collaboration.

- Artificial intelligence-powered lean templates: Enabling real-time analysis and decision-making.

- Mobile lean templates: Enabling employees to access and use templates on-the-go.

- Integrated lean templates: Allowing for seamless integration with other business systems and processes.

Conclusion and Next Steps

In conclusion, lean templates are powerful tools for organizations seeking to improve efficiency, productivity, and customer satisfaction. By understanding the benefits, types, and best practices for using lean templates, organizations can unlock significant value and drive continuous improvement. To get started, organizations should identify areas for improvement, select the right template, and provide training and support to employees. With the right approach and mindset, lean templates can help organizations to achieve their goals and stay competitive in today's fast-paced business environment.Lean Templates Image Gallery

What is a lean template?

+A lean template is a pre-designed document or spreadsheet that guides users through a specific process or methodology, typically used to support lean principles such as value stream mapping, root cause analysis, and continuous improvement.

What are the benefits of using lean templates?

+The benefits of using lean templates include improved efficiency, enhanced productivity, better decision-making, increased customer satisfaction, and cost savings.

How do I implement lean templates in my organization?

+To implement lean templates, identify areas for improvement, select the right template, customize the template to fit your specific needs, provide training and support to employees, and continuously monitor and evaluate the effectiveness of the template.

What are some common lean templates?

+Some common lean templates include value stream mapping templates, root cause analysis templates, Kaizen templates, Pareto analysis templates, and spaghetti diagrams.

How can I get started with lean templates?

+To get started with lean templates, identify areas for improvement, select the right template, and provide training and support to employees. You can also consult with lean experts or seek guidance from online resources and tutorials.

We hope this article has provided you with a comprehensive understanding of lean templates and their applications. If you have any further questions or would like to share your experiences with lean templates, please don't hesitate to comment below. Additionally, if you found this article helpful, please feel free to share it with your colleagues and friends. By working together, we can drive continuous improvement and achieve our goals in today's fast-paced business environment.