Intro

The use of laser technology has revolutionized various industries, including woodworking, metalworking, and construction. One of the most significant innovations in this field is the laser templator, a device that uses a laser beam to project a template or design onto a workpiece. This technology has greatly improved the accuracy and efficiency of various processes, from cutting and drilling to assembly and quality control. In this article, we will explore five ways a laser templator can benefit your work, whether you are a professional contractor, a hobbyist, or a business owner.

The importance of precision and accuracy cannot be overstated in industries where measurements and cuts need to be exact. Traditional methods of templating, such as using physical templates or manual measurements, can be time-consuming and prone to errors. The introduction of the laser templator has addressed these issues by providing a fast, accurate, and flexible way to project templates and designs onto various materials. This technology is not only limited to professional settings but can also be highly beneficial for DIY projects and small-scale manufacturing.

The versatility of laser templators makes them an invaluable tool across different sectors. From woodworking, where intricate designs and precise cuts are essential, to metal fabrication, where accuracy in cutting and drilling is crucial, the applications of laser templators are diverse. Moreover, in construction and renovation projects, laser templators can be used to ensure that fittings, fixtures, and other components are accurately positioned and aligned. The ease of use, coupled with the high degree of precision it offers, makes the laser templator an attractive option for both beginners and seasoned professionals.

Introduction to Laser Templators

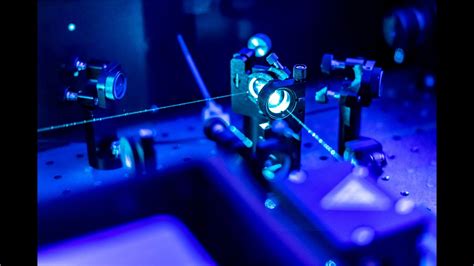

Laser templators work by projecting a laser beam onto a surface, creating a precise template or design that can be used as a guide for various operations such as cutting, drilling, or assembly. This technology is based on the principle of laser projection, where the laser beam is controlled and manipulated to create the desired pattern or template. The device can be programmed with specific designs or templates, allowing for a high degree of customization and flexibility.

The benefits of using a laser templator are numerous. It enhances precision, reducing errors and the need for rework. It also increases efficiency by speeding up the templating process, allowing for more work to be done in less time. Additionally, laser templators can improve safety by minimizing the risk of accidents caused by incorrect measurements or cuts. For businesses, the use of laser templators can lead to cost savings by reducing waste and improving productivity.

Applications of Laser Templators

Laser templators have a wide range of applications across different industries. In woodworking, they are used for creating intricate designs and patterns on wood, ensuring precise cuts and joints. In metal fabrication, laser templators are essential for accurately cutting and drilling metals, which is critical for the structural integrity and safety of the final product. In construction, these devices are used for ensuring that components such as pipes, ducts, and electrical wiring are precisely positioned and aligned.

The use of laser templators is not limited to these industries. They can also be found in sign making, where precise cuts and designs are necessary for creating professional-looking signs. In the manufacturing sector, laser templators can be used for quality control, ensuring that products meet specific standards and dimensions. The flexibility and accuracy of laser templators make them a valuable asset for any business or individual involved in manufacturing or construction.

Benefits of Laser Templators

The benefits of laser templators can be summarized into several key points. Firstly, they offer high precision, which is essential for achieving accurate cuts, drills, and assemblies. This precision not only improves the quality of the work but also reduces the need for rework, saving time and resources. Secondly, laser templators enhance efficiency by speeding up the templating process, allowing for more projects to be completed in less time. This increased productivity can lead to higher profits for businesses and more satisfaction for DIY enthusiasts.

Thirdly, laser templators improve safety by reducing the risk of accidents caused by incorrect measurements or cuts. In industries where safety is paramount, such as construction and manufacturing, the use of laser templators can significantly minimize risks. Finally, laser templators offer flexibility and customization, allowing users to create complex designs and patterns with ease. This feature is particularly beneficial for businesses that need to produce customized products or for hobbyists working on unique projects.

How to Choose the Right Laser Templator

Choosing the right laser templator depends on several factors, including the intended use, the type of materials to be worked with, and the level of precision required. For woodworking and sign making, a laser templator with high resolution and the ability to project intricate designs may be necessary. For metal fabrication and construction, a device with a strong and stable laser beam that can project templates onto large surfaces may be more appropriate.

The cost of the laser templator is also an important consideration. Devices with advanced features and higher precision tend to be more expensive. However, the long-term benefits of increased accuracy, efficiency, and safety can justify the initial investment. Additionally, the ease of use and the availability of customer support should be considered, especially for those who are new to using laser templators.

Future of Laser Templators

The future of laser templators looks promising, with advancements in technology expected to improve their precision, efficiency, and usability. One of the trends is the integration of laser templators with other technologies, such as CNC machines and 3D printers, to create fully automated production lines. This integration can further enhance productivity and accuracy, making laser templators an indispensable tool in modern manufacturing.

Another area of development is in the software used to program and control laser templators. More sophisticated software can allow for the creation of complex designs and patterns, as well as real-time adjustments and corrections. This can open up new possibilities for customization and innovation, particularly in industries where unique and intricate designs are highly valued.

Laser Templator Image Gallery

What is a laser templator and how does it work?

+A laser templator is a device that uses a laser beam to project a template or design onto a workpiece. It works by controlling and manipulating the laser beam to create the desired pattern or template, allowing for precise cuts, drills, and assemblies.

What are the benefits of using a laser templator?

+The benefits of using a laser templator include high precision, increased efficiency, improved safety, and the ability to create complex designs and patterns with ease. It also reduces the need for rework, saving time and resources.

How do I choose the right laser templator for my needs?

+Choosing the right laser templator depends on several factors, including the intended use, the type of materials to be worked with, and the level of precision required. Consider the cost, ease of use, and the availability of customer support when making your decision.

In conclusion, laser templators are powerful tools that offer a range of benefits, from precision and efficiency to safety and customization. Whether you are a professional contractor, a hobbyist, or a business owner, incorporating a laser templator into your workflow can significantly improve the quality and speed of your work. As technology continues to evolve, we can expect to see even more advanced features and applications of laser templators, further revolutionizing the way we work with materials. If you have any thoughts or questions about laser templators, feel free to share them in the comments below. Your feedback and insights are invaluable, and we look forward to hearing from you.