Intro

Track equipment upkeep with a free maintenance log Excel template, simplifying asset management, preventive maintenance, and repair scheduling for efficient equipment lifecycle management.

Maintaining equipment is crucial for ensuring the smooth operation of any business or organization. Effective maintenance helps prevent equipment failures, reduces downtime, and saves costs. One of the key tools in equipment maintenance is a maintenance log, which tracks and records all maintenance activities performed on equipment. For those looking for a straightforward and efficient way to manage their equipment maintenance, using a free equipment maintenance log Excel template can be highly beneficial.

Equipment maintenance involves regular checks, repairs, and replacements of parts to ensure that machinery and equipment are in good working condition. It is a preventive measure that helps in identifying potential issues before they become major problems. A well-organized maintenance schedule can significantly reduce the risk of equipment failure, thereby minimizing production losses and ensuring the safety of operators.

Using an Excel template for equipment maintenance logging offers several advantages. It is easy to use, even for those without extensive experience in maintenance management. Excel templates are highly customizable, allowing users to tailor the log to fit their specific needs and the types of equipment they are managing. Additionally, Excel provides powerful tools for data analysis, enabling users to track maintenance trends, identify frequently occurring issues, and make informed decisions about equipment upkeep and replacement.

For businesses or individuals managing multiple pieces of equipment, a maintenance log template in Excel can help streamline the process. It allows for the creation of a centralized database where all maintenance records are stored, making it easier to access historical data, plan future maintenance, and ensure compliance with regulatory requirements.

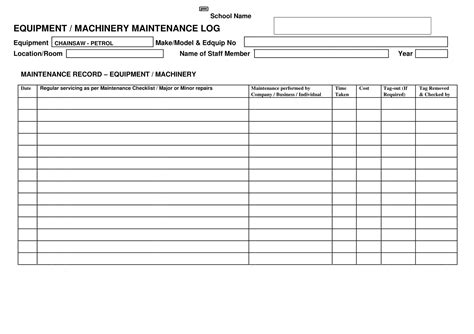

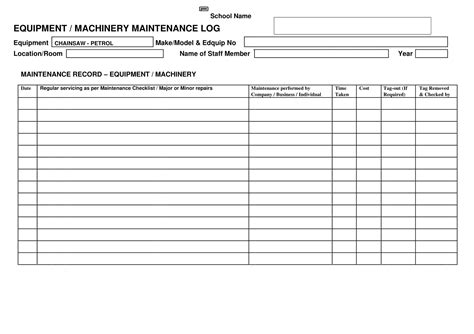

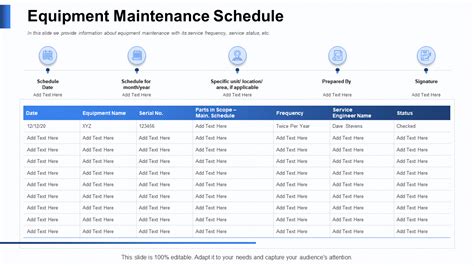

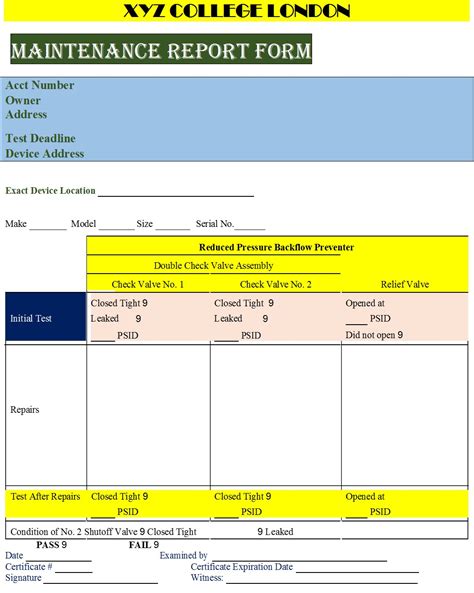

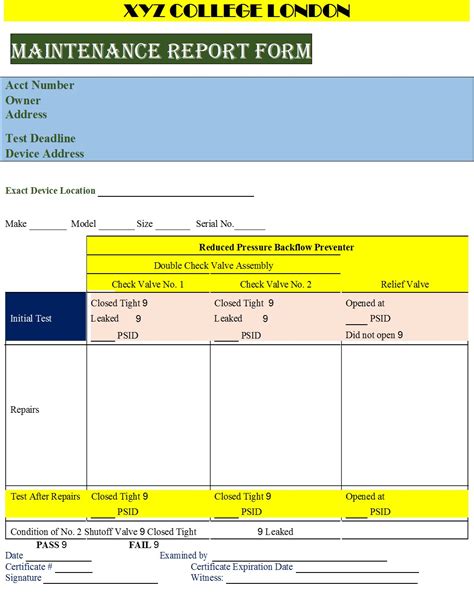

When selecting a free equipment maintenance log Excel template, it's essential to consider the features that will best support your maintenance management needs. A good template should include columns or sections for equipment identification (such as equipment name, model, and serial number), description of the maintenance performed, date of maintenance, parts replaced, and the person performing the maintenance. Some templates may also include spaces for noting the cost of maintenance, scheduling future maintenance, and tracking the equipment's operational hours or mileage.

Implementing an equipment maintenance log can have a significant impact on the efficiency and profitability of an organization. By systematically tracking maintenance, businesses can extend the lifespan of their equipment, reduce maintenance costs over time, and improve overall productivity. Moreover, a well-maintained piece of equipment is safer to operate, reducing the risk of accidents and injuries.

In addition to the direct benefits, maintaining accurate and detailed records of equipment maintenance can also play a critical role in regulatory compliance and audits. Many industries are subject to strict regulations regarding equipment safety and maintenance, and having a comprehensive log can provide the necessary documentation to demonstrate adherence to these standards.

For those new to equipment maintenance management, starting with a simple and free Excel template can be a good introduction to more comprehensive maintenance management systems. As the needs of the organization grow, the template can be expanded or migrated to more sophisticated software solutions that offer additional features such as automated scheduling, reminders, and mobile access.

In summary, utilizing a free equipment maintenance log Excel template is a practical step towards improving equipment reliability, reducing downtime, and enhancing operational efficiency. Its ease of use, flexibility, and analytical capabilities make it an invaluable tool for maintenance professionals and business owners alike.

Benefits of Equipment Maintenance Logging

The benefits of maintaining an equipment maintenance log are multifaceted, ranging from financial savings to enhanced safety and compliance. Some of the key advantages include:

- Extended Equipment Life: Regular maintenance helps in identifying and addressing issues before they cause significant damage, thereby extending the lifespan of the equipment.

- Reduced Downtime: By performing maintenance on a scheduled basis, the likelihood of unexpected equipment failures is minimized, reducing downtime and the associated losses.

- Improved Safety: Well-maintained equipment is safer to operate, reducing the risk of accidents and ensuring a safer working environment.

- Cost Savings: Preventive maintenance can reduce the need for costly repairs and replacements, leading to significant cost savings over time.

- Enhanced Efficiency: Equipment that is properly maintained operates more efficiently, leading to increased productivity and better quality outputs.

How to Use an Equipment Maintenance Log Template

Using an equipment maintenance log template involves several steps, from setting up the template to regularly updating it with maintenance information. Here’s a simplified guide:

- Download and Customize the Template: Start by downloading a free equipment maintenance log Excel template. Customize it according to your needs by adding or removing columns as necessary.

- Enter Equipment Information: Begin by entering the details of each piece of equipment, including its name, model, serial number, and any other relevant identifiers.

- Record Maintenance Activities: Each time maintenance is performed on a piece of equipment, record the details in the log. This should include the date of maintenance, a description of the work done, parts replaced, and the name of the person who performed the maintenance.

- Schedule Future Maintenance: Use the template to schedule future maintenance activities. This can be based on the manufacturer’s recommendations, the equipment’s operational hours, or other relevant factors.

- Regularly Review and Update: Regularly review the maintenance log to identify trends, plan for future maintenance, and ensure that all equipment is up to date with its maintenance schedule.

Features of an Effective Equipment Maintenance Log

An effective equipment maintenance log should have several key features to ensure it meets its purpose of tracking and managing equipment maintenance efficiently. Some of these features include:

- Equipment Identification: A unique identifier for each piece of equipment to ensure that maintenance records are accurately attributed.

- Maintenance History: A detailed record of all maintenance activities performed on the equipment, including dates, descriptions of work, and parts replaced.

- Scheduling Tool: The ability to schedule future maintenance based on various criteria such as time elapsed, operational hours, or manufacturer recommendations.

- Cost Tracking: A section to record the costs associated with maintenance, including labor and parts, to help in budgeting and cost analysis.

- Analysis and Reporting: The capability to generate reports and analyze maintenance data to identify trends, frequent issues, and areas for improvement.

Best Practices for Equipment Maintenance

Adhering to best practices in equipment maintenance is crucial for maximizing the effectiveness of a maintenance program. Some key best practices include:

- Preventive Maintenance: Regularly performing routine maintenance tasks such as cleaning, lubricating, and inspecting equipment to prevent failures.

- Predictive Maintenance: Using techniques such as condition monitoring and predictive analytics to forecast when maintenance should be performed.

- Continuous Improvement: Regularly reviewing maintenance processes and implementing changes to improve efficiency and effectiveness.

- Training and Education: Ensuring that maintenance personnel are properly trained and educated on the equipment they are maintaining and the latest maintenance techniques.

- Safety First: Prioritizing safety in all maintenance activities to protect both the equipment and the personnel performing the maintenance.

Gallery of Equipment Maintenance

Equipment Maintenance Image Gallery

Frequently Asked Questions

What is the purpose of an equipment maintenance log?

+The purpose of an equipment maintenance log is to track and record all maintenance activities performed on equipment, helping in the identification of trends, planning of future maintenance, and ensuring compliance with regulatory requirements.

How often should equipment maintenance be performed?

+The frequency of equipment maintenance depends on several factors including the type of equipment, its usage, and the manufacturer’s recommendations. It can range from daily checks to monthly or yearly maintenance schedules.

What are the benefits of using an Excel template for equipment maintenance logging?

+Using an Excel template for equipment maintenance logging offers several benefits including ease of use, customization, and powerful data analysis capabilities. It helps in streamlining the maintenance process, reducing errors, and improving decision-making.

How can an equipment maintenance log contribute to cost savings?

+An equipment maintenance log can contribute to cost savings by helping in the identification of maintenance needs before they become major issues, reducing the need for costly repairs, and optimizing maintenance schedules to minimize downtime and extend equipment life.

What role does preventive maintenance play in equipment upkeep?

+Preventive maintenance plays a crucial role in equipment upkeep by preventing equipment failures, reducing downtime, and improving safety. It involves performing routine tasks such as cleaning, lubricating, and inspecting equipment on a regular basis.

In conclusion, maintaining an accurate and detailed equipment maintenance log is essential for any organization that relies on equipment for its operations. By leveraging a free equipment maintenance log Excel template and following best practices in equipment maintenance, businesses can ensure their equipment operates efficiently, safely, and reliably. This not only leads to cost savings and improved productivity but also contributes to a safer working environment and better compliance with regulatory standards. We invite readers to share their experiences with equipment maintenance logging and to explore how implementing such a system can benefit their operations. Whether you're looking to streamline your maintenance processes, reduce costs, or simply ensure your equipment is always in good working condition, an equipment maintenance log is a valuable tool that can help you achieve your goals.