Intro

Boost fleet efficiency with 5 expert maintenance tips, covering vehicle inspection, scheduling, and repair strategies to minimize downtime and reduce costs, ensuring optimal fleet performance and reliability.

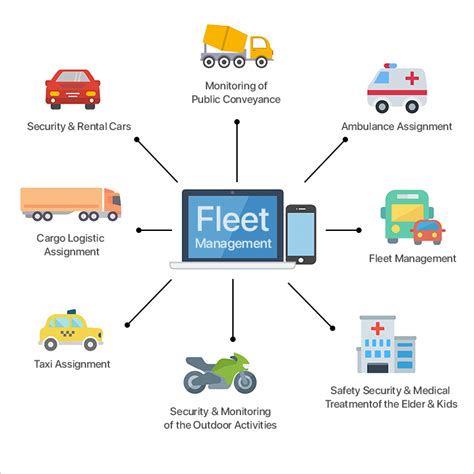

The importance of fleet maintenance cannot be overstated, as it plays a crucial role in ensuring the safety and efficiency of vehicles, as well as reducing costs and environmental impact. A well-maintained fleet is essential for businesses that rely on transportation, such as logistics, delivery services, and construction companies. In this article, we will explore the importance of fleet maintenance and provide valuable tips on how to keep your fleet running smoothly.

Effective fleet maintenance involves a combination of regular inspections, timely repairs, and proactive measures to prevent breakdowns and extend the lifespan of vehicles. By implementing a comprehensive maintenance program, businesses can minimize downtime, reduce fuel consumption, and lower emissions. Moreover, a well-maintained fleet can also improve driver safety, reduce the risk of accidents, and enhance the overall reputation of the company.

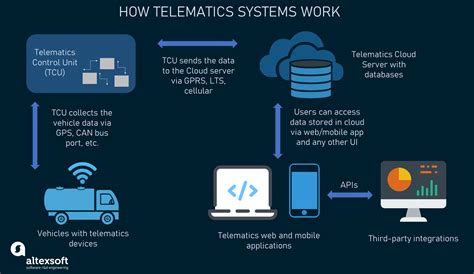

Fleet maintenance is a complex task that requires careful planning, organization, and execution. It involves a range of activities, including vehicle inspections, maintenance scheduling, parts inventory management, and repair services. With the increasing complexity of modern vehicles, fleet maintenance has become a specialized field that requires expertise and resources. In this article, we will provide practical tips and insights on how to maintain a fleet of vehicles, including best practices, tools, and technologies that can help optimize fleet performance.

Fleet Maintenance Strategies

Benefits of Fleet Maintenance

The benefits of fleet maintenance are numerous and well-documented. Some of the key advantages of a well-maintained fleet include: * Improved safety: A well-maintained fleet reduces the risk of accidents and enhances driver safety * Increased efficiency: Regular maintenance can improve fuel efficiency, reduce emissions, and lower operating costs * Reduced downtime: Preventive maintenance can minimize breakdowns and reduce the need for costly repairs * Extended vehicle lifespan: Regular maintenance can extend the lifespan of vehicles, reducing the need for premature replacements * Enhanced reputation: A well-maintained fleet can enhance the reputation of a company, demonstrating a commitment to safety, quality, and customer serviceFleet Maintenance Tips

Best Practices for Fleet Maintenance

Some best practices for fleet maintenance include: * Regular vehicle inspections to identify potential issues before they become major problems * Preventive maintenance, such as oil changes, tire rotations, and brake pad replacements * Repair services, including routine repairs, major overhauls, and collision repairs * Parts inventory management to ensure that essential parts are available when needed * Maintenance scheduling to optimize vehicle availability and minimize downtime * Driver training on vehicle maintenance and repair procedures * Technician training on fleet maintenance best practices and repair techniquesFleet Maintenance Technologies

Challenges in Fleet Maintenance

Some challenges in fleet maintenance include: * Limited resources: Fleet maintenance can be resource-intensive, requiring significant investments in personnel, equipment, and technology. * Complexity: Modern vehicles are complex systems that require specialized knowledge and expertise to maintain and repair. * Downtime: Vehicle downtime can be costly, reducing productivity and impacting customer service. * Regulatory compliance: Fleet maintenance must comply with regulatory requirements, including safety standards, emissions regulations, and labor laws.Fleet Maintenance and Safety

Environmental Impact of Fleet Maintenance

The environmental impact of fleet maintenance is a significant concern, as vehicles can emit greenhouse gases, pollutants, and other harmful emissions. Some key environmental considerations in fleet maintenance include: * Fuel efficiency: Regular maintenance can improve fuel efficiency, reducing emissions and lowering operating costs. * Emissions regulations: Fleet maintenance must comply with emissions regulations, including standards for particulate matter, nitrogen oxides, and other pollutants. * Alternative fuels: Fleet maintenance can involve the use of alternative fuels, such as biodiesel, electric, and hybrid vehicles. * Sustainable practices: Fleet maintenance can involve sustainable practices, such as recycling, waste reduction, and energy-efficient operations.Fleet Maintenance Image Gallery

What is fleet maintenance?

+Fleet maintenance refers to the activities and processes involved in maintaining and repairing a fleet of vehicles, including inspections, preventive maintenance, repair services, and parts inventory management.

Why is fleet maintenance important?

+Fleet maintenance is important because it ensures the safety and efficiency of vehicles, reduces downtime and operating costs, and enhances the reputation of a company.

What are some best practices for fleet maintenance?

+Some best practices for fleet maintenance include regular vehicle inspections, preventive maintenance, repair services, parts inventory management, and maintenance scheduling.

In summary, fleet maintenance is a critical aspect of managing a fleet of vehicles, and it requires careful planning, organization, and execution. By implementing a comprehensive maintenance program, businesses can minimize downtime, reduce costs, and enhance the safety and efficiency of their fleet. We hope this article has provided valuable insights and tips on how to maintain a fleet of vehicles, and we encourage readers to share their own experiences and best practices in the comments below. Additionally, we invite readers to share this article with others who may be interested in fleet maintenance, and to explore other resources and articles on this topic.