Intro

Discover 5 essential flange size charts for precise piping measurements, including nominal pipe sizes, pressure ratings, and material specs for seamless connections and fittings.

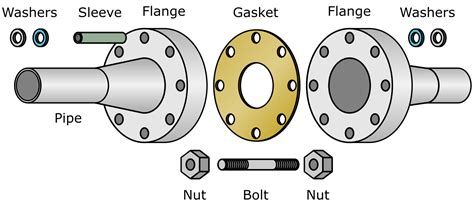

The importance of accurate measurements and specifications cannot be overstated in various industries, including engineering, construction, and manufacturing. One crucial aspect of ensuring the integrity and safety of systems and structures is the use of flanges. Flanges are essential components that connect pipes, valves, and other equipment, facilitating the transportation of fluids and gases. The size and type of flange used can significantly impact the performance and reliability of these systems. In this article, we will delve into the world of flange size charts, exploring their significance, types, and applications.

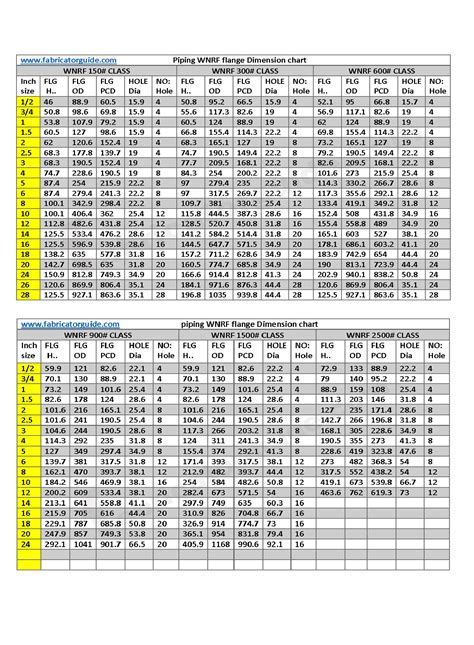

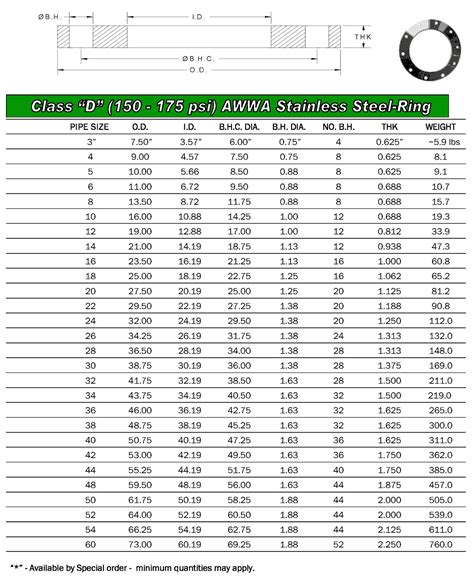

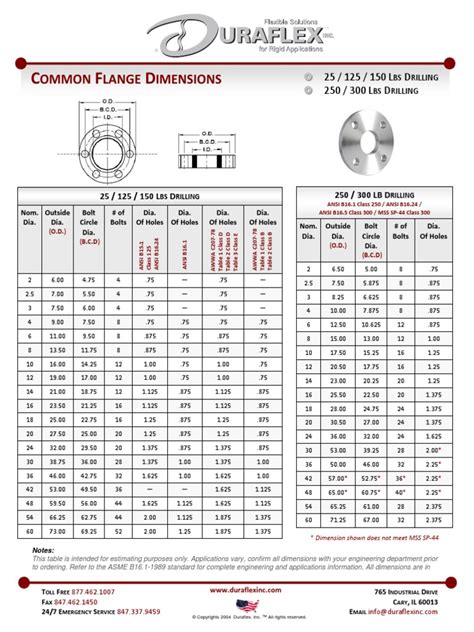

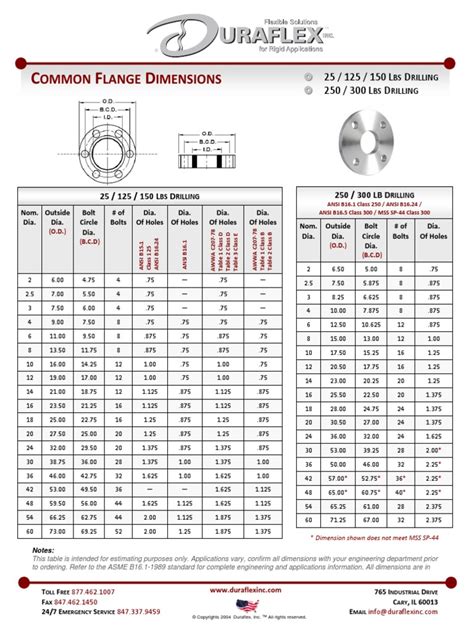

Flange size charts are comprehensive guides that provide detailed information on the dimensions, ratings, and specifications of various flanges. These charts are invaluable resources for engineers, technicians, and industry professionals, enabling them to select the correct flange for their specific needs. With numerous types of flanges available, each designed for particular applications and operating conditions, the use of flange size charts helps ensure that the chosen flange meets the required standards and regulations.

The selection of the appropriate flange size is critical to prevent leaks, ruptures, and other failures that can lead to costly repairs, downtime, and even safety hazards. Flange size charts offer a systematic approach to identifying the correct flange size, taking into account factors such as pipe size, pressure rating, material, and connection type. By referencing these charts, professionals can verify the compatibility of flanges with other system components, guaranteeing a secure and efficient connection.

Introduction to Flange Size Charts

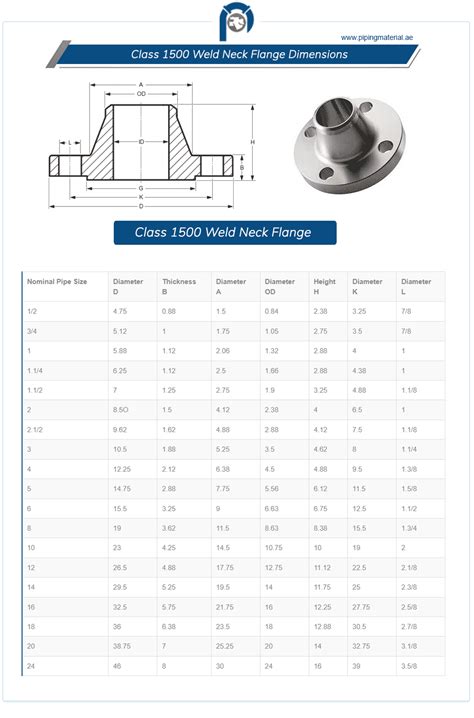

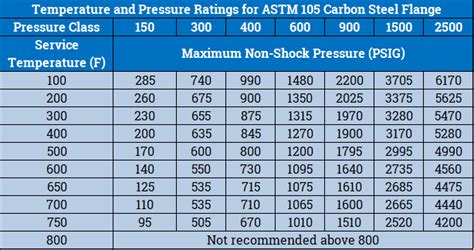

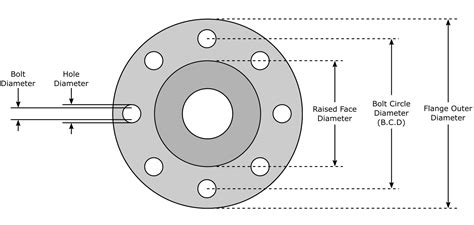

Flange size charts are typically organized by flange type, size, and rating, making it easier to locate specific information. These charts may include dimensions such as the flange outer diameter, inner diameter, bolt circle diameter, and bolt hole diameter. Additionally, they may provide information on the flange's pressure rating, temperature range, and material specifications. By consulting flange size charts, users can quickly determine the suitable flange for their application, reducing the risk of errors and ensuring compliance with industry standards.

Types of Flange Size Charts

There are several types of flange size charts available, catering to different industries and applications. Some common types include:

- ASME flange size charts, which conform to the standards set by the American Society of Mechanical Engineers

- API flange size charts, designed for use in the oil and gas industry

- DIN flange size charts, which adhere to German industry standards

- JIS flange size charts, used in Japanese industries Each type of flange size chart is tailored to specific requirements and regulations, ensuring that users can find the information they need for their particular application.

Applications of Flange Size Charts

Flange size charts have a wide range of applications across various industries, including:

- Oil and gas production and transportation

- Chemical processing and manufacturing

- Power generation and distribution

- Water treatment and supply

- HVAC and piping systems In each of these industries, flange size charts play a vital role in ensuring the safe and efficient operation of systems and equipment. By selecting the correct flange size and type, professionals can prevent accidents, reduce maintenance costs, and optimize system performance.

Benefits of Using Flange Size Charts

The use of flange size charts offers numerous benefits, including:

- Improved safety: By selecting the correct flange size and type, professionals can reduce the risk of accidents and injuries

- Increased efficiency: Flange size charts enable users to quickly identify the suitable flange for their application, streamlining the design and installation process

- Cost savings: Using the correct flange size and type can help prevent costly repairs, downtime, and replacement of faulty components

- Enhanced reliability: Flange size charts ensure that systems and equipment are designed and installed to meet industry standards and regulations, guaranteeing reliable operation and performance

How to Read Flange Size Charts

Reading flange size charts requires a basic understanding of the terminology and symbols used. Here are some steps to follow:

- Identify the flange type and size: Locate the relevant section of the chart and find the specified flange size and type.

- Determine the pressure rating: Check the chart for the recommended pressure rating for the selected flange size and type.

- Verify the material specifications: Ensure that the flange material meets the required standards and regulations for the application.

- Check the dimensions: Verify the flange dimensions, including the outer diameter, inner diameter, bolt circle diameter, and bolt hole diameter.

Common Mistakes to Avoid When Using Flange Size Charts

When using flange size charts, it is essential to avoid common mistakes that can lead to incorrect flange selection. Some mistakes to watch out for include:

- Misinterpreting the chart: Ensure that you understand the terminology and symbols used in the chart.

- Selecting the wrong flange type: Choose the correct flange type for your application, considering factors such as pressure rating, material, and connection type.

- Ignoring industry standards: Always adhere to relevant industry standards and regulations when selecting and installing flanges.

Gallery of Flange Size Charts

Flange Size Charts Image Gallery

What is the purpose of flange size charts?

+Flange size charts provide detailed information on the dimensions, ratings, and specifications of various flanges, enabling users to select the correct flange for their specific needs.

How do I read a flange size chart?

+To read a flange size chart, identify the flange type and size, determine the pressure rating, verify the material specifications, and check the dimensions.

What are the benefits of using flange size charts?

+The benefits of using flange size charts include improved safety, increased efficiency, cost savings, and enhanced reliability.

What are the common mistakes to avoid when using flange size charts?

+Common mistakes to avoid include misinterpreting the chart, selecting the wrong flange type, and ignoring industry standards.

How do I select the correct flange size and type for my application?

+To select the correct flange size and type, consult the relevant flange size chart, considering factors such as pressure rating, material, and connection type.

In conclusion, flange size charts are indispensable tools for industry professionals, providing critical information for the selection and installation of flanges. By understanding the importance of flange size charts, their types, applications, and benefits, users can ensure the safe and efficient operation of systems and equipment. Remember to avoid common mistakes and always adhere to industry standards and regulations when working with flanges. If you have any further questions or would like to share your experiences with flange size charts, please feel free to comment below or share this article with your colleagues and friends.