Intro

Streamline equipment management with 5 customizable log templates, featuring maintenance tracking, inventory control, and asset monitoring, to boost efficiency and reduce downtime in industrial operations and equipment maintenance schedules.

The importance of equipment log templates cannot be overstated, particularly in industries where machinery and equipment play a crucial role in daily operations. Whether it's manufacturing, construction, or healthcare, keeping track of equipment usage, maintenance, and repairs is essential for ensuring efficiency, safety, and compliance with regulatory standards. In this article, we will delve into the world of equipment log templates, exploring their benefits, types, and how to create effective ones.

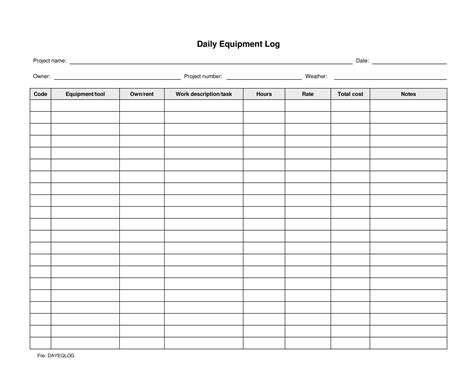

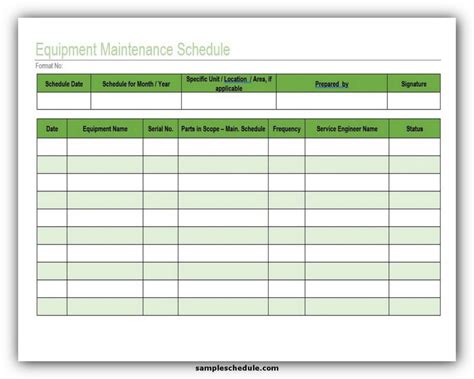

Effective equipment management is key to minimizing downtime, reducing costs, and optimizing resource allocation. One of the primary tools in achieving this is the equipment log, a detailed record of all activities related to a piece of equipment. This includes installation dates, usage hours, maintenance schedules, repair histories, and even operator training records. By maintaining accurate and up-to-date equipment logs, organizations can make informed decisions about equipment replacement, predict potential failures, and ensure that all machinery is functioning at its best.

The use of equipment log templates simplifies the process of creating and maintaining these records. Templates provide a structured format, ensuring that all necessary information is captured consistently across different types of equipment and over time. This consistency is crucial for analyzing trends, identifying areas for improvement, and facilitating audits or inspections. Moreover, with the advancement in digital technologies, equipment log templates can be easily created, shared, and updated electronically, enhancing accessibility and reducing the clutter associated with paper-based systems.

Benefits of Equipment Log Templates

The benefits of using equipment log templates are multifaceted. Firstly, they enhance organization and efficiency by providing a standardized method for recording equipment data. This standardization makes it easier to compare and analyze the performance of different equipment, aiding in strategic decision-making. Secondly, these templates contribute to improved safety by ensuring that maintenance and inspections are conducted regularly and thoroughly, reducing the risk of accidents caused by malfunctioning equipment. Lastly, equipment log templates play a significant role in compliance, as they help organizations meet regulatory requirements by maintaining detailed, auditable records of equipment maintenance and usage.

Types of Equipment Log Templates

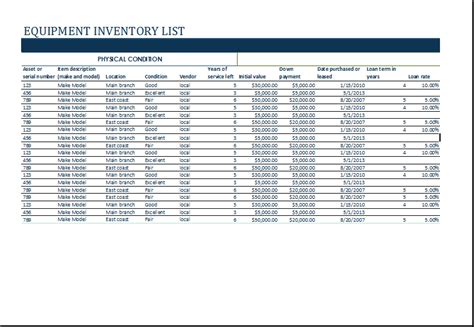

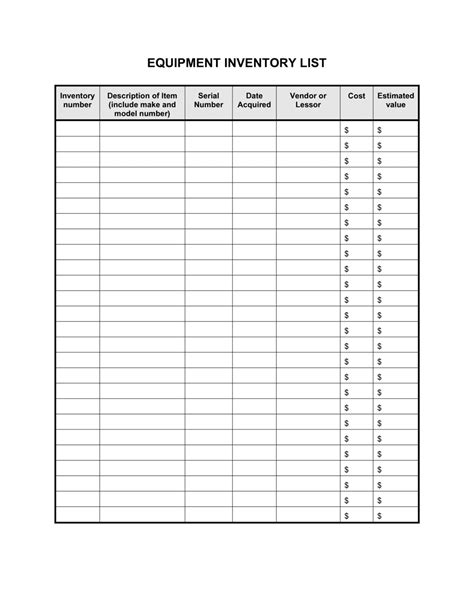

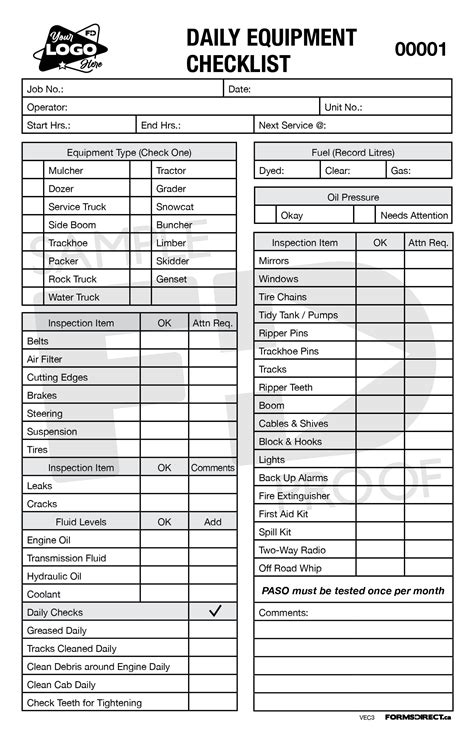

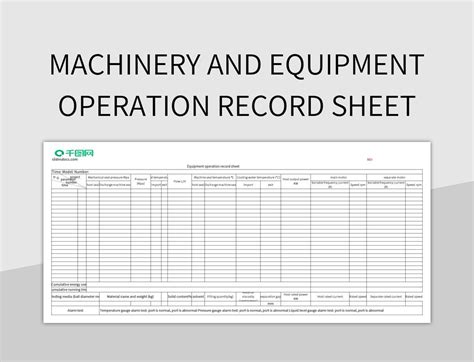

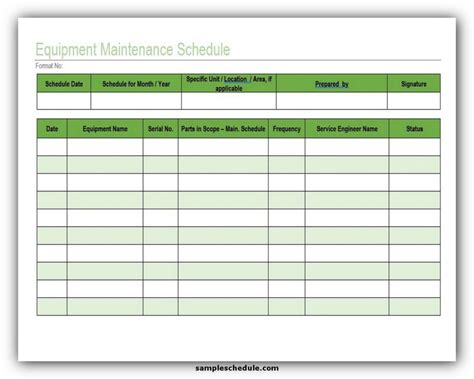

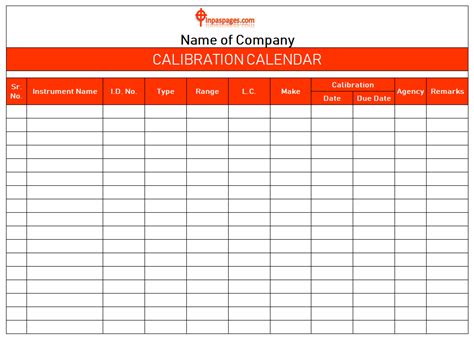

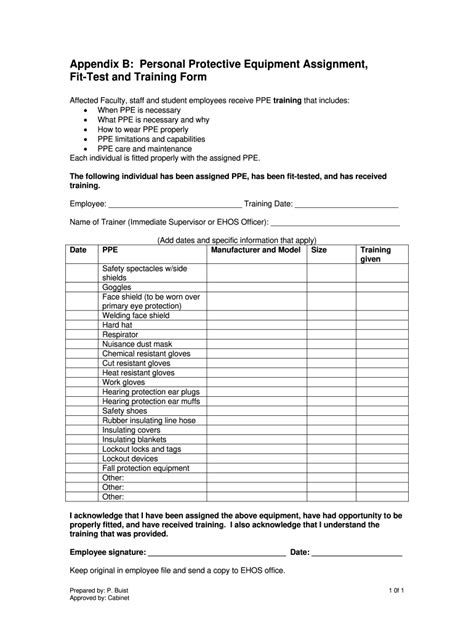

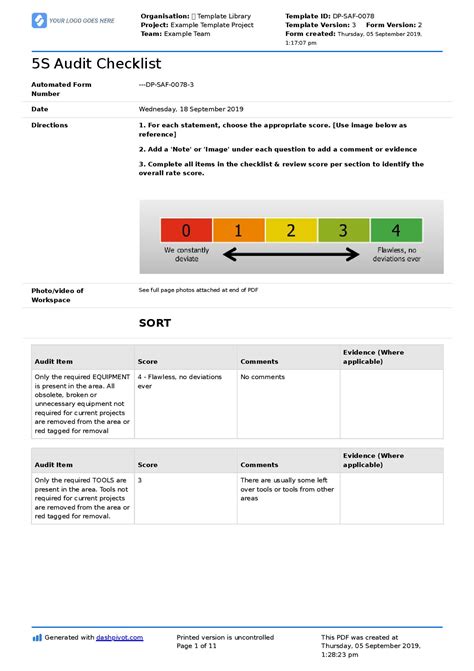

Equipment log templates can be categorized based on their application, complexity, and the type of information they capture. Simple templates might focus on basic details such as equipment identification, location, and maintenance schedules. More complex templates, on the other hand, can include detailed operational logs, performance metrics, and even space for noting observations or issues encountered during use. The choice of template depends on the specific needs of the organization, the nature of the equipment, and the regulatory environment in which it operates.Creating Effective Equipment Log Templates

Creating effective equipment log templates involves several key steps. Firstly, it's essential to identify the types of equipment that need to be tracked and the specific information that must be recorded for each. This could include serial numbers, model numbers, purchase dates, and warranty information. Secondly, the template should be designed to capture both routine and exceptional data, such as scheduled maintenance, unscheduled repairs, and any safety incidents. The template's layout should be intuitive and easy to use, minimizing the time spent on data entry and reducing the likelihood of errors.

A critical aspect of effective equipment log templates is their adaptability. As operations evolve, and new equipment is introduced, the templates should be flexible enough to accommodate these changes without requiring a complete overhaul. This might involve using digital tools that allow for easy modification of template fields or the creation of new templates from existing ones.

Steps to Implement Equipment Log Templates

Implementing equipment log templates within an organization involves several practical steps: - **Identification of Needs**: Determine which equipment requires logging and what information needs to be tracked. - **Template Design**: Create or select templates that meet these needs, considering both the type of equipment and the regulatory requirements. - **Training**: Ensure that all personnel responsible for maintaining the equipment logs are trained on how to use the templates correctly. - **Integration**: Integrate the equipment log system with existing maintenance and operational processes to ensure seamless data flow and minimize additional workload. - **Review and Update**: Regularly review the effectiveness of the templates and update them as necessary to reflect changes in operations or equipment.Practical Examples of Equipment Log Templates

In practice, equipment log templates can vary significantly depending on the industry and the specific application. For instance, in healthcare, an equipment log template for a dialysis machine might include fields for patient identification, treatment duration, and dialysate flow rates, alongside maintenance and calibration records. In contrast, a template for a construction crane would focus on operational hours, load tests, and maintenance of wire ropes and other critical components.

Statistical Data on Equipment Log Templates

Studies and surveys have shown that organizations using equipment log templates experience a significant reduction in equipment downtime and an improvement in overall operational efficiency. For example, a manufacturing plant that implemented a comprehensive equipment logging system reported a 25% decrease in unplanned maintenance and a 15% increase in production capacity within the first year. Such statistics underscore the importance of adopting and effectively utilizing equipment log templates in various industries.Gallery of Equipment Log Templates

Equipment Log Templates Gallery

FAQs on Equipment Log Templates

What is the primary purpose of using equipment log templates?

+The primary purpose of using equipment log templates is to maintain accurate and detailed records of equipment usage, maintenance, and repairs, ensuring efficiency, safety, and compliance with regulatory standards.

How do equipment log templates contribute to operational efficiency?

+Equipment log templates contribute to operational efficiency by providing a standardized method for recording equipment data, facilitating the identification of trends, prediction of potential failures, and optimization of maintenance schedules.

Can equipment log templates be customized for specific industries or equipment types?

+Yes, equipment log templates can be customized to meet the specific needs of different industries or equipment types, ensuring that they capture all relevant information necessary for effective equipment management.

What are the benefits of using digital equipment log templates?

+The benefits of using digital equipment log templates include enhanced accessibility, ease of updates, and the ability to automate certain processes, such as scheduling maintenance and generating reports.

How often should equipment log templates be reviewed and updated?

+Equipment log templates should be reviewed and updated regularly, ideally every 6-12 months, or as needed based on changes in operations, equipment, or regulatory requirements.

In conclusion, equipment log templates are indispensable tools for organizations seeking to optimize their equipment management practices. By understanding the benefits, types, and best practices for creating and implementing these templates, businesses can enhance their operational efficiency, ensure compliance, and ultimately improve their bottom line. Whether you're in the process of adopting equipment log templates for the first time or looking to refine your existing systems, the insights provided here aim to guide you toward more effective equipment management. We invite you to share your experiences, ask questions, or explore further resources on this topic, contributing to a community that values excellence in equipment management.