Intro

Discover 5 ways to scan inventory efficiently, streamlining stock management with barcode scanning, RFID tracking, and mobile inventory apps, boosting accuracy and productivity in warehouse management and inventory control systems.

The importance of inventory management cannot be overstated, especially in today's fast-paced business environment. Effective inventory management is crucial for companies to stay competitive, reduce costs, and improve customer satisfaction. One key aspect of inventory management is scanning inventory, which involves using technology to track and manage inventory levels. In this article, we will explore the different ways to scan inventory, highlighting the benefits and best practices for each method.

Inventory scanning is a critical process that helps businesses to maintain accurate inventory records, reduce errors, and improve operational efficiency. With the rise of technology, there are now various ways to scan inventory, each with its own advantages and disadvantages. Whether you are a small business owner or a large corporation, understanding the different methods of scanning inventory can help you to make informed decisions and improve your inventory management processes.

Scanning inventory is not just about using a barcode scanner or a mobile app; it involves a range of technologies and techniques that can be tailored to meet the specific needs of your business. From manual scanning to automated scanning, there are various methods to choose from, each with its own benefits and limitations. In this article, we will delve into the different ways to scan inventory, exploring the pros and cons of each method and providing practical examples and tips for implementation.

Introduction to Scan Inventory

Inventory scanning is a process that involves using technology to track and manage inventory levels. It is a critical aspect of inventory management, as it helps businesses to maintain accurate inventory records, reduce errors, and improve operational efficiency. There are various ways to scan inventory, including manual scanning, automated scanning, and mobile scanning. Each method has its own advantages and disadvantages, and the choice of method depends on the specific needs of the business.

Benefits of Scan Inventory

The benefits of scanning inventory are numerous, including improved accuracy, reduced errors, and increased efficiency. Scanning inventory also helps businesses to maintain accurate inventory records, which is critical for making informed decisions about production, pricing, and inventory levels. Additionally, scanning inventory can help businesses to reduce costs, improve customer satisfaction, and stay competitive in the market.Method 1: Manual Scanning

Manual scanning involves using a barcode scanner or a manual data entry system to track and manage inventory levels. This method is simple and cost-effective, making it a popular choice for small businesses or businesses with limited inventory. However, manual scanning can be time-consuming and prone to errors, especially for large inventories. To implement manual scanning, businesses can use barcode scanners or manual data entry systems, such as spreadsheets or inventory management software.

Best Practices for Manual Scanning

To get the most out of manual scanning, businesses should follow best practices, such as: * Using high-quality barcode scanners or manual data entry systems * Training staff on how to use the scanning system * Implementing a regular scanning schedule * Verifying inventory records regularlyMethod 2: Automated Scanning

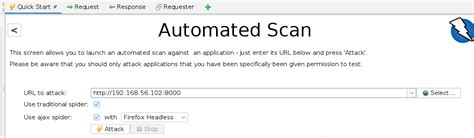

Automated scanning involves using automated systems, such as RFID tags or automated storage and retrieval systems, to track and manage inventory levels. This method is more accurate and efficient than manual scanning, making it a popular choice for large businesses or businesses with complex inventory. However, automated scanning can be expensive to implement and maintain, making it a less viable option for small businesses.

Benefits of Automated Scanning

The benefits of automated scanning include: * Improved accuracy and efficiency * Reduced labor costs * Increased inventory visibility * Improved customer satisfactionMethod 3: Mobile Scanning

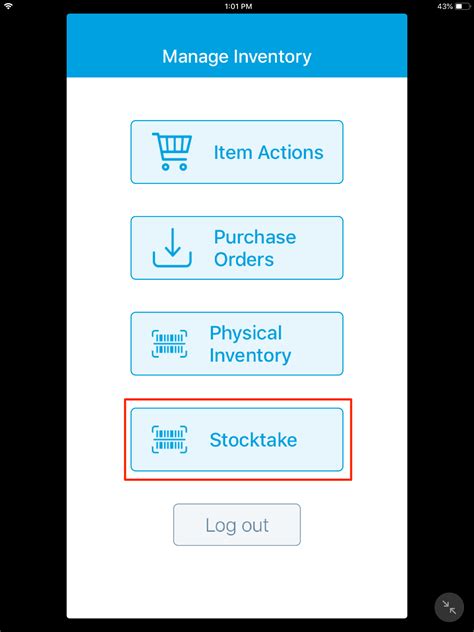

Mobile scanning involves using mobile devices, such as smartphones or tablets, to track and manage inventory levels. This method is flexible and cost-effective, making it a popular choice for businesses with mobile workforces. Mobile scanning can be used to track inventory in real-time, reducing errors and improving operational efficiency.

Best Practices for Mobile Scanning

To get the most out of mobile scanning, businesses should follow best practices, such as: * Using high-quality mobile devices and scanning apps * Training staff on how to use the mobile scanning system * Implementing a regular scanning schedule * Verifying inventory records regularlyMethod 4: Barcode Scanning

Barcode scanning involves using barcode scanners to track and manage inventory levels. This method is simple and cost-effective, making it a popular choice for small businesses or businesses with limited inventory. Barcode scanning can be used to track inventory in real-time, reducing errors and improving operational efficiency.

Benefits of Barcode Scanning

The benefits of barcode scanning include: * Improved accuracy and efficiency * Reduced labor costs * Increased inventory visibility * Improved customer satisfactionMethod 5: RFID Scanning

RFID scanning involves using RFID tags to track and manage inventory levels. This method is more accurate and efficient than barcode scanning, making it a popular choice for large businesses or businesses with complex inventory. RFID scanning can be used to track inventory in real-time, reducing errors and improving operational efficiency.

Best Practices for RFID Scanning

To get the most out of RFID scanning, businesses should follow best practices, such as: * Using high-quality RFID tags and scanning systems * Training staff on how to use the RFID scanning system * Implementing a regular scanning schedule * Verifying inventory records regularlyInventory Scanning Image Gallery

What is inventory scanning?

+Inventory scanning is the process of using technology to track and manage inventory levels.

What are the benefits of inventory scanning?

+The benefits of inventory scanning include improved accuracy, reduced errors, and increased efficiency.

What are the different methods of inventory scanning?

+The different methods of inventory scanning include manual scanning, automated scanning, mobile scanning, barcode scanning, and RFID scanning.

How can I choose the best inventory scanning method for my business?

+To choose the best inventory scanning method for your business, consider factors such as the size and complexity of your inventory, the level of accuracy required, and the cost of implementation and maintenance.

What are the best practices for inventory scanning?

+The best practices for inventory scanning include using high-quality scanning systems, training staff on how to use the scanning system, implementing a regular scanning schedule, and verifying inventory records regularly.

In conclusion, scanning inventory is a critical process that can help businesses to maintain accurate inventory records, reduce errors, and improve operational efficiency. By understanding the different methods of scanning inventory and following best practices, businesses can choose the best method for their needs and improve their inventory management processes. Whether you are a small business owner or a large corporation, scanning inventory is an essential aspect of inventory management that can help you to stay competitive, reduce costs, and improve customer satisfaction. We invite you to share your thoughts and experiences with inventory scanning in the comments below, and to explore our other articles on inventory management and related topics.