Intro

Boost aerospace quality with 5 AS9100 tips, enhancing ISO standards, audit preparedness, and risk management for optimal compliance and certification success.

Implementing AS9100, a quality management standard for the aerospace industry, can be a complex and challenging process. However, with the right approach, organizations can achieve significant benefits, including improved quality, increased efficiency, and enhanced customer satisfaction. In this article, we will explore five tips for implementing AS9100, providing guidance on how to navigate the standard's requirements and achieve certification.

The importance of AS9100 cannot be overstated. The aerospace industry is heavily regulated, and companies that supply products or services to this sector must demonstrate their commitment to quality and reliability. AS9100 provides a framework for achieving this, outlining the requirements for a quality management system (QMS) that can help organizations meet the industry's stringent standards. By implementing AS9100, companies can improve their reputation, increase customer trust, and gain a competitive advantage in the market.

AS9100 is based on the ISO 9001 standard, but it includes additional requirements that are specific to the aerospace industry. These requirements include risk management, configuration management, and control of external providers. To implement AS9100, organizations must first understand these requirements and how they apply to their business. This involves reviewing the standard, identifying the relevant clauses, and determining how to implement them in their QMS. It also requires a commitment to continuous improvement, as the standard is regularly updated to reflect changes in the industry and best practices.

Understanding the AS9100 Standard

Key Components of AS9100

The key components of AS9100 include: * Quality policy and objectives * Quality manual * Procedures and records * Training and awareness * Internal audits and management review * Continuous improvement These components are essential to the QMS, as they provide the framework for achieving quality and reliability. By implementing these components, organizations can demonstrate their commitment to AS9100 and achieve certification.Implementing AS9100

Steps to Implement AS9100

The steps to implement AS9100 include: 1. Review the standard and assess the current QMS 2. Identify the gaps and develop a plan to address them 3. Establish a quality policy and objectives 4. Develop a quality manual and procedures 5. Implement training and awareness programs 6. Conduct internal audits and management review 7. Continuously improve the QMSMaintaining AS9100 Certification

Benefits of AS9100 Certification

The benefits of AS9100 certification include: * Improved quality and reliability * Increased efficiency and productivity * Enhanced customer satisfaction * Increased competitiveness * Access to new markets and customersCommon Challenges in AS9100 Implementation

Overcoming AS9100 Implementation Challenges

To overcome these challenges, organizations can: * Seek guidance from consultants and experts * Develop a phased implementation plan * Provide training and awareness programs for employees * Establish a strong quality culture * Continuously monitor and improve the QMSAS9100 Audit and Certification Process

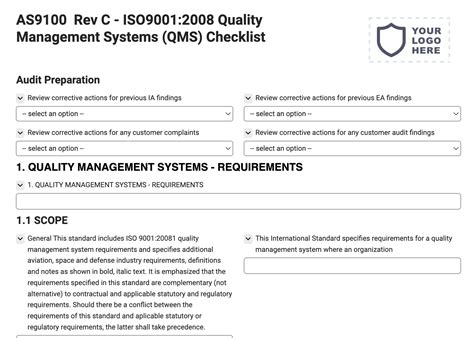

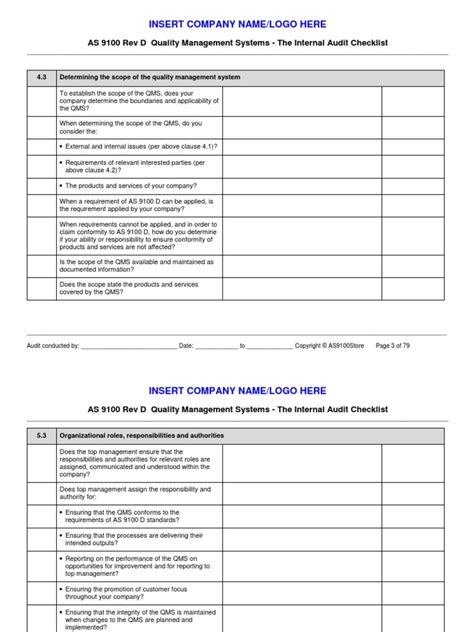

Preparing for an AS9100 Audit

To prepare for an AS9100 audit, organizations should: * Review the standard and ensure compliance * Develop a quality manual and procedures * Establish a strong quality culture * Provide training and awareness programs for employees * Continuously monitor and improve the QMSAS9100 Image Gallery

What is AS9100 and why is it important?

+AS9100 is a quality management standard for the aerospace industry. It is important because it provides a framework for achieving quality and reliability, which are critical in the aerospace sector.

How do I implement AS9100 in my organization?

+To implement AS9100, you should review the standard, assess your current QMS, identify gaps, and develop a plan to address them. You should also establish a quality policy and objectives, develop a quality manual and procedures, and provide training and awareness programs for employees.

What are the benefits of AS9100 certification?

+The benefits of AS9100 certification include improved quality and reliability, increased efficiency and productivity, enhanced customer satisfaction, increased competitiveness, and access to new markets and customers.

How do I prepare for an AS9100 audit?

+To prepare for an AS9100 audit, you should review the standard, ensure compliance, develop a quality manual and procedures, establish a strong quality culture, provide training and awareness programs for employees, and continuously monitor and improve the QMS.

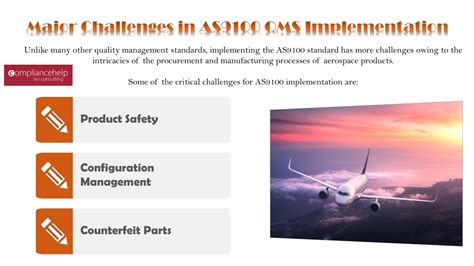

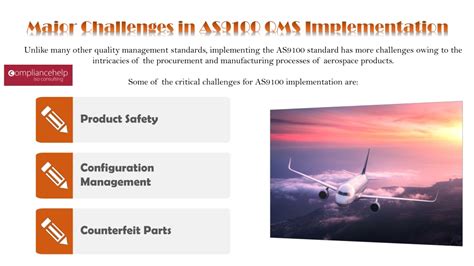

What are the common challenges in AS9100 implementation?

+The common challenges in AS9100 implementation include lack of resources and expertise, limited budget and funding, insufficient training and awareness, difficulty in implementing the standard's requirements, and limited support from top management.

In conclusion, implementing AS9100 requires a structured approach, starting with a review of the standard and an assessment of the organization's current QMS. By following the tips outlined in this article, organizations can navigate the standard's requirements, achieve certification, and improve their quality and reliability. We encourage readers to share their experiences and tips for implementing AS9100, and to ask questions about the standard and its requirements. By working together, we can promote a culture of quality and excellence in the aerospace industry.