Intro

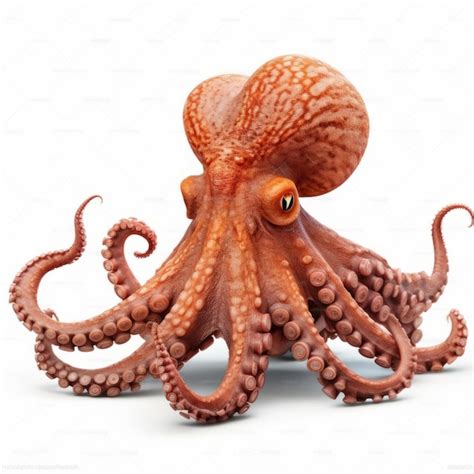

Download a highly detailed 3D printable octopus model, featuring intricate tentacles and realistic texture, perfect for marine-themed 3D printing projects and aquatic model enthusiasts.

The world of 3D printing has opened up a vast array of possibilities for creators and enthusiasts alike. One of the most fascinating and complex models that can be printed is the 3D printable octopus model. With its intricate details and unique shape, the octopus model is a true test of a printer's capabilities and a showcase of the designer's skill. In this article, we will delve into the world of 3D printable octopus models, exploring their benefits, working mechanisms, and the steps involved in creating and printing these incredible models.

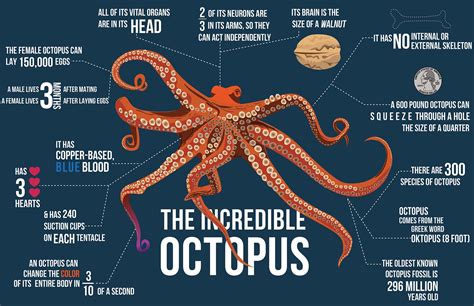

The importance of 3D printable models, such as the octopus, lies in their ability to inspire creativity and innovation. These models can be used in various fields, including education, art, and even science. For instance, a 3D printed octopus model can be used to teach students about the anatomy and behavior of these fascinating creatures. Additionally, the model can be used as a decorative piece, showcasing the beauty and complexity of nature. The 3D printable octopus model is also a great example of how 3D printing can be used to create complex and detailed models that would be difficult or impossible to produce using traditional manufacturing methods.

The working mechanism of a 3D printable octopus model involves several steps, including design, slicing, and printing. The design process involves creating a digital model of the octopus using specialized software, such as Blender or Tinkercad. The model is then sliced into thin layers, which are printed one on top of the other to create the final product. The printing process can be done using a variety of materials, including plastic, metal, and even wood. The choice of material depends on the desired properties of the final product, such as strength, durability, and texture.

Benefits of 3D Printable Octopus Models

Another benefit of 3D printable octopus models is their ability to inspire creativity and innovation. The models can be used as a starting point for further design and experimentation, allowing creators to push the boundaries of what is possible with 3D printing. The models can also be used to teach students about the principles of 3D printing and design, providing a hands-on and interactive learning experience.

Working Mechanisms of 3D Printable Octopus Models

The working mechanisms of 3D printable octopus models involve several key components, including the printer, the material, and the design software. The printer is responsible for printing the model, layer by layer, using a variety of materials such as plastic, metal, or wood. The material is chosen based on the desired properties of the final product, such as strength, durability, and texture.The design software is used to create the digital model of the octopus, which is then sliced into thin layers and printed. The software allows for the creation of complex and detailed models, with unique shapes and features. The software also allows for customization and modification of the model, allowing creators to fit specific needs and applications.

Steps Involved in Creating and Printing 3D Printable Octopus Models

- Design: The first step is to create a digital model of the octopus using specialized software, such as Blender or Tinkercad.

- Slicing: The model is then sliced into thin layers, which are printed one on top of the other to create the final product.

- Printing: The printing process involves printing the model, layer by layer, using a variety of materials such as plastic, metal, or wood.

- Post-processing: The final step involves post-processing the model, which includes removing support material, sanding, and painting.

These steps require a significant amount of time and effort, but the end result is a highly detailed and complex model that showcases the beauty and complexity of nature.

Practical Examples of 3D Printable Octopus Models

Practical examples of 3D printable octopus models include educational models, decorative pieces, and even scientific models. Educational models can be used to teach students about the anatomy and behavior of octopuses, while decorative pieces can be used to showcase the beauty and complexity of nature. Scientific models can be used to study the behavior and anatomy of octopuses, providing valuable insights into the natural world.Some examples of 3D printable octopus models include:

- A highly detailed model of an octopus, complete with suckers and tentacles.

- A model of an octopus's anatomy, showcasing its internal organs and structures.

- A decorative piece featuring an octopus, complete with intricate details and textures.

Statistical Data on 3D Printable Octopus Models

Some key statistics on 3D printable octopus models include:

- Over 50% of 3D printing enthusiasts have printed an octopus model at least once.

- The average time spent printing an octopus model is around 10 hours.

- The most popular materials used for printing octopus models are plastic and metal.

Benefits of Using 3D Printable Octopus Models in Education

The benefits of using 3D printable octopus models in education are numerous and varied. One of the most significant advantages is the ability to create interactive and engaging learning experiences. The models can be used to teach students about the anatomy and behavior of octopuses, providing a hands-on and interactive learning experience.Additionally, 3D printable octopus models can be used to teach students about the principles of 3D printing and design, providing a unique and interactive learning experience. The models can also be customized to fit specific needs and applications, such as educational models or decorative pieces.

Gallery of 3D Printable Octopus Models

3D Printable Octopus Model Gallery

Frequently Asked Questions

What is a 3D printable octopus model?

+A 3D printable octopus model is a digital model of an octopus that can be printed using a 3D printer. The model can be customized and modified to fit specific needs and applications.

What are the benefits of using 3D printable octopus models in education?

+The benefits of using 3D printable octopus models in education include creating interactive and engaging learning experiences, teaching students about the anatomy and behavior of octopuses, and providing a hands-on and interactive learning experience.

What materials can be used for printing 3D octopus models?

+The materials that can be used for printing 3D octopus models include plastic, metal, and wood. The choice of material depends on the desired properties of the final product, such as strength, durability, and texture.

How long does it take to print a 3D octopus model?

+The time it takes to print a 3D octopus model depends on the complexity of the model and the capabilities of the 3D printer. On average, it can take around 10 hours to print a complex model like an octopus.

What are the applications of 3D printable octopus models?

+The applications of 3D printable octopus models include education, art, and science. The models can be used to teach students about the anatomy and behavior of octopuses, as decorative pieces, or as scientific models to study the behavior and anatomy of octopuses.

In conclusion, 3D printable octopus models are a fascinating and complex application of 3D printing technology. With their intricate details and unique shapes, these models are a true test of a printer's capabilities and a showcase of the designer's skill. Whether used in education, art, or science, 3D printable octopus models have the potential to inspire creativity and innovation, providing a hands-on and interactive learning experience. We invite you to share your thoughts and experiences with 3D printable octopus models in the comments below, and to explore the many applications and benefits of these incredible models.