Intro

Discover 3D print chainmail, a revolutionary technique combining additive manufacturing and medieval armor, utilizing metal printing, chainmail patterns, and 3D modeling for innovative, flexible, and protective designs.

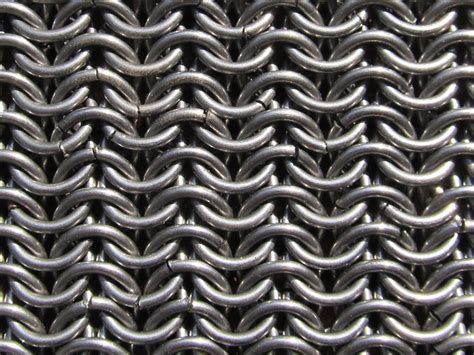

The concept of 3D printing chainmail has garnered significant attention in recent years, particularly among enthusiasts of historical armor and innovative manufacturing techniques. Chainmail, a type of armor made from interlocking metal rings, has been a cornerstone of protective gear throughout history, from ancient civilizations to medieval knights. The advent of 3D printing technology has opened new avenues for the creation of chainmail, offering unprecedented flexibility, precision, and accessibility. This article delves into the importance of 3D printing chainmail, its benefits, the working mechanisms behind its creation, and the potential applications of this innovative technique.

The historical significance of chainmail as a protective armor is undeniable. Its flexibility and strength made it a preferred choice for warriors across various cultures. However, the traditional method of crafting chainmail is labor-intensive and requires a high level of skill, limiting its accessibility and making it a time-consuming process. The integration of 3D printing technology into the manufacturing process of chainmail addresses these challenges, enabling the rapid production of complex patterns and designs that would be difficult or impossible to achieve through traditional methods.

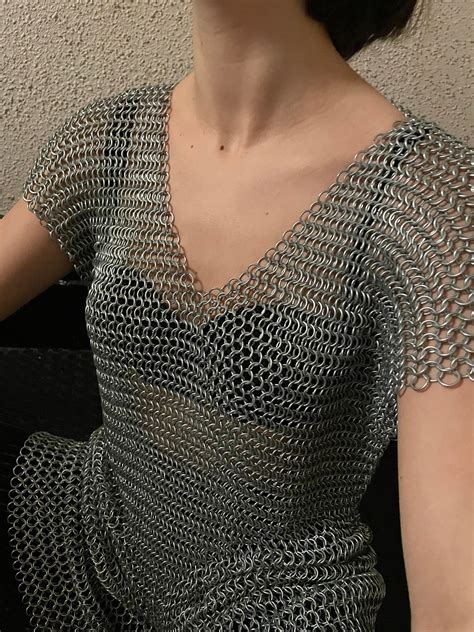

Furthermore, 3D printing chainmail offers a unique blend of historical authenticity and modern innovation. Enthusiasts and historians can now recreate historical armor with precision, while designers and engineers can explore new materials and patterns that enhance the protective qualities of chainmail. This fusion of old and new has the potential to revolutionize not only the field of historical reenactments but also the development of modern protective gear, such as body armor for military and law enforcement personnel.

Introduction to 3D Printing Chainmail

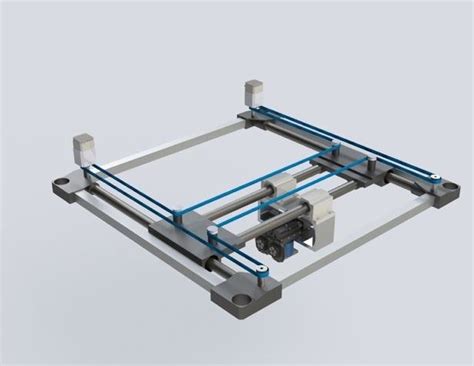

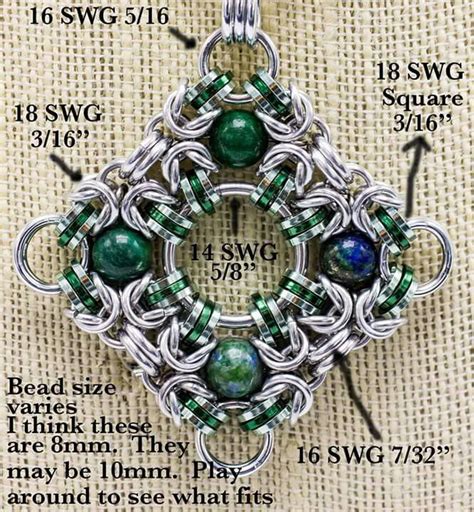

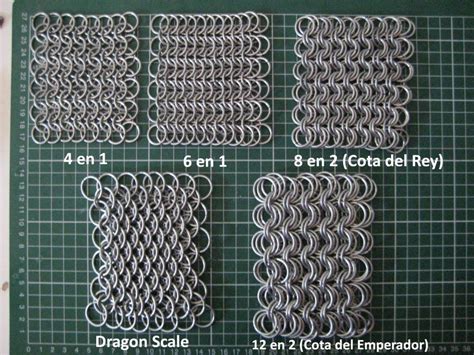

The process of 3D printing chainmail involves several key steps, starting with design. Computer-aided design (CAD) software is used to create the digital model of the chainmail pattern, taking into account the desired level of protection, flexibility, and aesthetic appeal. Once the design is finalized, it is sent to a 3D printer, which lays down the material, typically metal or a metal-infused filament, layer by layer, according to the design specifications. The choice of material is crucial, as it affects the durability, weight, and protective capabilities of the chainmail.

Benefits of 3D Printed Chainmail

The benefits of 3D printed chainmail are multifaceted: - **Customization**: Allows for the creation of tailored fit and design, enhancing comfort and protection. - **Innovation**: Enables the experimentation with new materials and patterns that can improve the protective qualities of chainmail. - **Accessibility**: Makes chainmail more accessible to a wider audience, including historical reenactors, cosplayers, and potentially, military and law enforcement personnel. - **Efficiency**: Significantly reduces the time and skill required to produce chainmail compared to traditional methods.The Working Mechanism of 3D Printing Chainmail

Understanding the working mechanism of 3D printing chainmail requires a look into the 3D printing process itself. There are several types of 3D printing technologies, but for metal or metal-infused materials, techniques like Selective Laser Sintering (SLS) or Fused Deposition Modeling (FDM) are commonly used. SLS involves the use of a laser to fuse together metal powders, layer by layer, while FDM melts and extrudes metal-infused filament to build the chainmail pattern. The choice of technology depends on the desired properties of the final product, including strength, durability, and cost.

Steps Involved in 3D Printing Chainmail

The steps involved in 3D printing chainmail include: 1. **Design**: Creating a digital model of the chainmail using CAD software. 2. **Material Selection**: Choosing the appropriate material based on the intended use of the chainmail. 3. **3D Printing**: Sending the design to a 3D printer and initiating the printing process. 4. **Post-processing**: Removing the printed chainmail from the printer and performing any necessary finishing touches, such as polishing or assembling the pieces.Applications of 3D Printed Chainmail

The applications of 3D printed chainmail are diverse and expanding. Historically, chainmail was used primarily for armor, but with the advent of 3D printing, its potential uses extend beyond historical reenactments and into modern protective gear. For instance, 3D printed chainmail could be used to create innovative body armor for military and law enforcement personnel, offering improved protection without sacrificing mobility. Additionally, its unique aesthetic appeal makes it an attractive material for fashion and art, allowing designers to create intricate and complex designs that were previously impossible to produce.

Future Perspectives

Looking into the future, the potential of 3D printed chainmail seems limitless. As 3D printing technology continues to evolve, we can expect to see advancements in material science, leading to stronger, lighter, and more versatile chainmail. The integration of smart materials and technologies, such as sensors and monitoring systems, could further enhance the protective and functional capabilities of chainmail. Moreover, the democratization of 3D printing technology could lead to a community-driven approach to chainmail design and production, fostering innovation and collaboration among enthusiasts and professionals alike.Gallery of 3D Printed Chainmail

3D Printed Chainmail Image Gallery

What is 3D printed chainmail used for?

+3D printed chainmail is used for a variety of purposes, including historical reenactments, fashion, art, and potentially, as a material for modern protective gear.

How is 3D printed chainmail made?

+3D printed chainmail is made using 3D printing technology, where a digital design of the chainmail pattern is sent to a 3D printer, which then lays down the material, layer by layer, according to the design specifications.

What are the benefits of 3D printed chainmail over traditional chainmail?

+The benefits include customization, innovation, accessibility, and efficiency. 3D printed chainmail can be tailored to fit specific needs, allows for the creation of complex designs, is more accessible to produce, and can be made more quickly than traditional chainmail.

As we continue to explore the possibilities of 3D printing chainmail, it's clear that this technology has the potential to not only preserve historical practices but also to push the boundaries of innovation and creativity. Whether you're a historian, a designer, or simply someone fascinated by the intersection of technology and tradition, 3D printed chainmail offers a compelling glimpse into what the future of manufacturing and design might hold. We invite you to share your thoughts, experiences, and ideas about 3D printed chainmail, and to explore how this technology can be harnessed to create new and exciting applications across various fields.