Intro

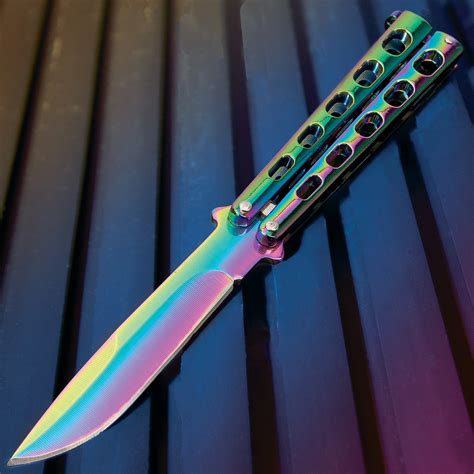

Discover the art of 3D print butterfly knife design, featuring intricate mechanisms, customizable models, and precise printing techniques for a unique pocket knife experience.

The art of creating a 3D print butterfly knife is a fascinating topic that has garnered significant attention in recent years. With the advancements in 3D printing technology, enthusiasts and makers can now design and create complex objects, including functional knives. In this article, we will delve into the world of 3D printing and explore the process of creating a butterfly knife, highlighting the benefits, challenges, and key considerations.

The importance of 3D printing in modern manufacturing cannot be overstated. This technology has revolutionized the way we design, prototype, and produce objects, allowing for increased complexity, customization, and speed. The application of 3D printing in the creation of functional items, such as knives, has opened up new avenues for innovation and experimentation. For those interested in creating a 3D print butterfly knife, it is essential to understand the basics of 3D printing, knife design, and the materials used in the process.

Butterfly knives, also known as balisongs, have been a popular choice among knife enthusiasts for their unique design and functionality. These knives feature a distinctive folding mechanism, which allows the blade to be concealed within the handle. The process of creating a 3D print butterfly knife requires careful consideration of the design, materials, and printing techniques. With the right tools and knowledge, makers can create a functional and visually stunning butterfly knife that showcases their creativity and skill.

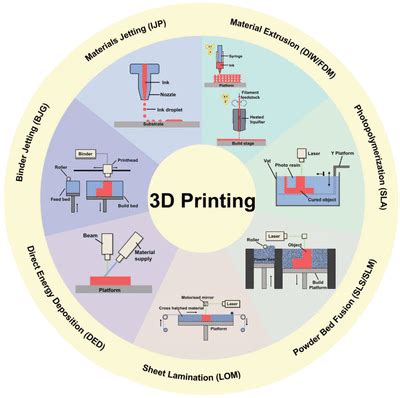

Introduction to 3D Printing

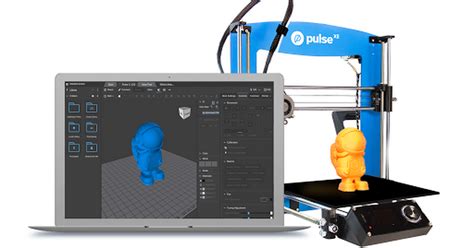

To create a 3D print butterfly knife, it is essential to understand the basics of 3D printing. This technology involves the layer-by-layer creation of objects using a variety of materials, including plastics, metals, and ceramics. The most common 3D printing techniques used for creating functional items, such as knives, are Fused Deposition Modeling (FDM) and Stereolithography (SLA). FDM is a popular choice for its affordability and versatility, while SLA offers higher resolution and accuracy.

Designing a Butterfly Knife

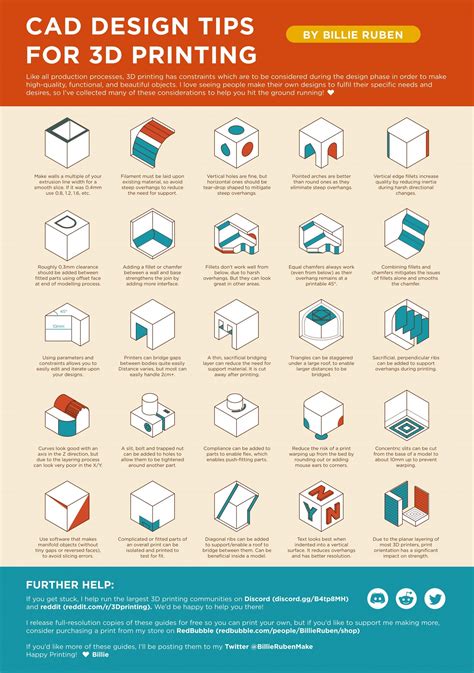

Designing a butterfly knife requires careful consideration of the mechanics, ergonomics, and aesthetics. The knife's folding mechanism, blade shape, and handle design must be carefully planned to ensure smooth operation and functionality. Makers can use computer-aided design (CAD) software to create a digital model of the knife, taking into account the materials, printing techniques, and intended use.

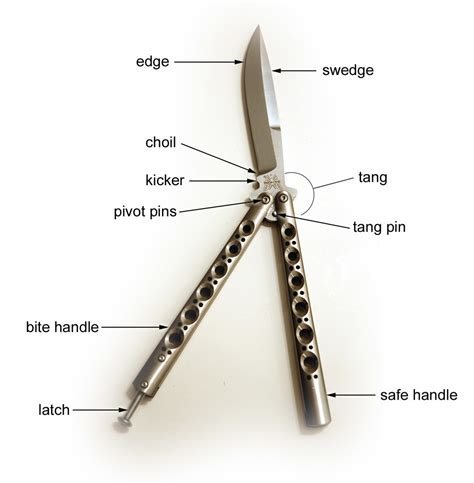

Key Components of a Butterfly Knife

The main components of a butterfly knife include: * Handle: The handle is the outer casing of the knife, which houses the blade and folding mechanism. * Blade: The blade is the cutting edge of the knife, which is typically made from a high-carbon steel or other durable materials. * Pivot: The pivot is the hinge that connects the blade to the handle, allowing it to fold and unfold. * Tang: The tang is the portion of the blade that extends into the handle, providing additional strength and stability.Materials and Printing Techniques

The choice of materials and printing techniques is crucial when creating a 3D print butterfly knife. The most common materials used for 3D printing knives are:

- PLA (Polylactic Acid): A biodegradable and renewable plastic, suitable for prototype development and proof-of-concept designs.

- ABS (Acrylonitrile Butadiene Styrene): A strong and impact-resistant plastic, commonly used for functional items, such as knives.

- Metal-filled filaments: These filaments contain metal powders or fibers, which provide increased strength, durability, and thermal conductivity.

Post-Printing Processing

After printing, the knife may require additional processing to achieve the desired finish and functionality. This can include: * Sanding and polishing: To smooth out the surface and remove any layer lines or imperfections. * Heat treatment: To increase the hardness and durability of the blade. * Assembly: To attach the blade, pivot, and other components to the handle.Challenges and Considerations

Creating a 3D print butterfly knife can be a complex and challenging process, requiring careful consideration of several factors, including:

- Material limitations: The strength, durability, and thermal conductivity of 3D printed materials may not match those of traditionally manufactured knives.

- Printing accuracy: The accuracy and resolution of the 3D printing process can affect the overall quality and functionality of the knife.

- Safety concerns: The creation and use of functional knives pose safety risks, which must be carefully managed and mitigated.

Tips and Best Practices

To ensure a successful and safe 3D printing experience, follow these tips and best practices: * Use high-quality materials and printing equipment to minimize defects and errors. * Follow proper safety protocols when handling and using functional knives. * Continuously test and refine the design to ensure optimal performance and functionality.Butterfly Knife Image Gallery

What is the best material for 3D printing a butterfly knife?

+The best material for 3D printing a butterfly knife depends on the intended use and desired properties. Common materials used for 3D printing knives include PLA, ABS, and metal-filled filaments.

How do I ensure the safety of my 3D printed butterfly knife?

+To ensure the safety of your 3D printed butterfly knife, follow proper safety protocols when handling and using the knife, and continuously test and refine the design to ensure optimal performance and functionality.

Can I use my 3D printed butterfly knife for everyday carry?

+While it is possible to use a 3D printed butterfly knife for everyday carry, it is essential to consider the material limitations, printing accuracy, and safety concerns before doing so. It is recommended to consult with local authorities and experts to ensure compliance with relevant laws and regulations.

In conclusion, creating a 3D print butterfly knife is a complex and challenging process that requires careful consideration of design, materials, and printing techniques. By following the tips and best practices outlined in this article, makers can create a functional and visually stunning butterfly knife that showcases their creativity and skill. We invite you to share your experiences and thoughts on 3D printing and knife making, and to explore the possibilities of this exciting and rapidly evolving field.